Aircraft structural frames and stringers dimensional measurement

Enhancing measurement cycle times for aircraft frames and stringers in shop-floor environments

Contact us

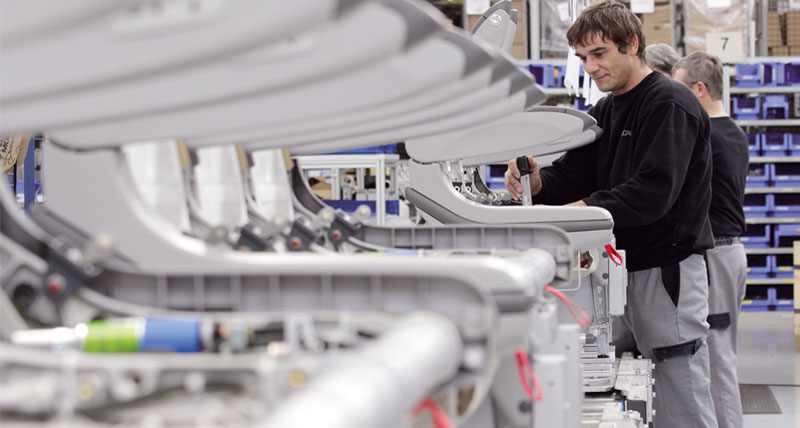

Producing parts of a high enough quality to guarantee the structural safety of an aircraft is the top priority for manufacturers of frames and stringers. But OEMs and suppliers also need to ensure high levels of production efficiency if they are to keep their costs under control and meet high demand for parts.

Dimensional measurement plays a crucial role in assuring that aircraft frames and stringers meet exacting quality standards. But manufacturers of large aircraft structures need to choose their metrology system carefully if it is to have a positive impact on measurement cycle times and, by extension, cost.

Because stringers and frames are large, linear, metal parts that are difficult to transport and easy to damage they need to be controlled for quality either on the shop floor or as close as possible to the machining centre. And since there are hundreds of frames and stringers in each aircraft, manufacturers need a metrology system that can measure them efficiently while consistently attaining high levels of accuracy, which can be as tight as 0.01 mm.

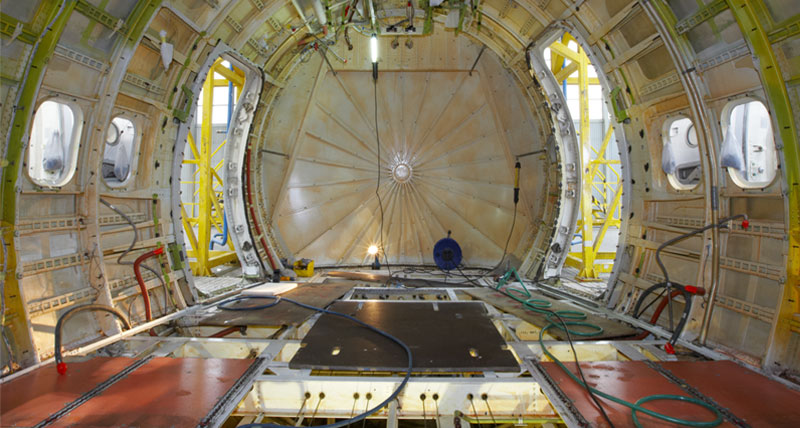

To be effective any metrology system must be able to accommodate a challenging shop-floor environment and include features such as structural thermal compensation software, which cancels out the influence of temperature on the accuracy of measurement results. It also needs to be versatile enough to switch between different parts and cope with different surfaces.

Hexagon’s gantry coordinate measuring machines (CMMs) and laser tracker measurement solutions have been developed to meet the aerospace industry’s exacting requirements when inspecting large aerospace tooling, components and assemblies on or near the shop floor. They deliver high-accuracy measurement off-line, near-line or in-line for large parts with a wide range of surfaces and finishes, supported by Hexagon’s industry-leading metrology software.

Our solutions

Large volume CMMs

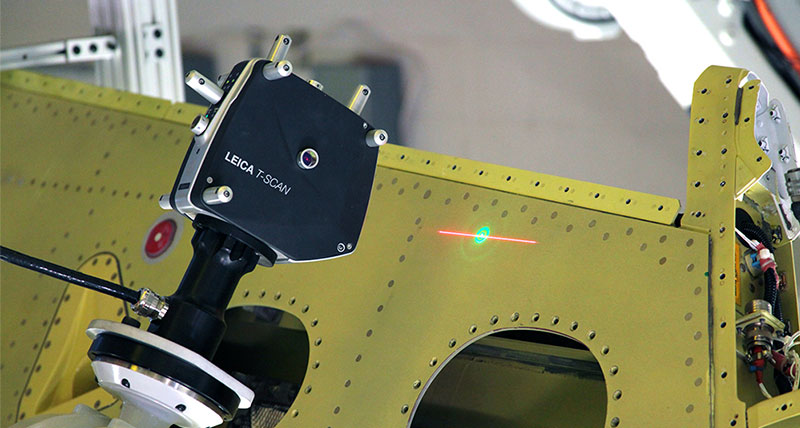

Automated laser tracker scanning

Large-volume metrology software

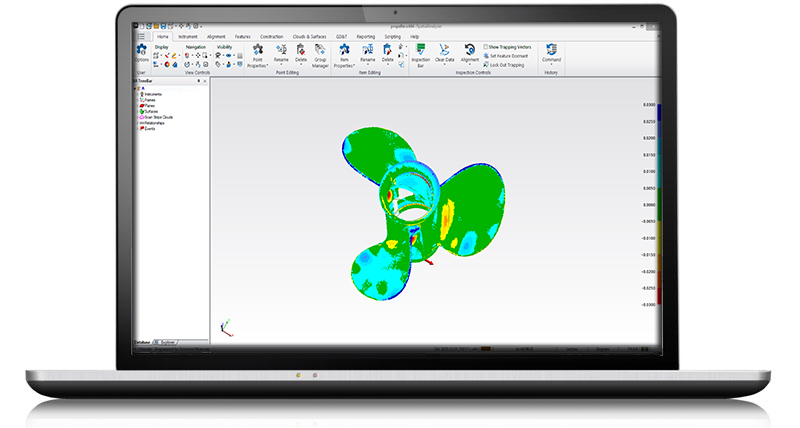

Designed specifically for large-volume spatial measurement, SpatialAnalyzer is the ideal software for aircraft assembly operations.

.jpg?h=428&iar=0&w=800&hash=DDCB977F4EB4679941709078EB9BE0CF)