Mould and die design and manufacturing

Ensure quality in tooling, mould and die with CAD CAM for mould and die design and manufacturing.

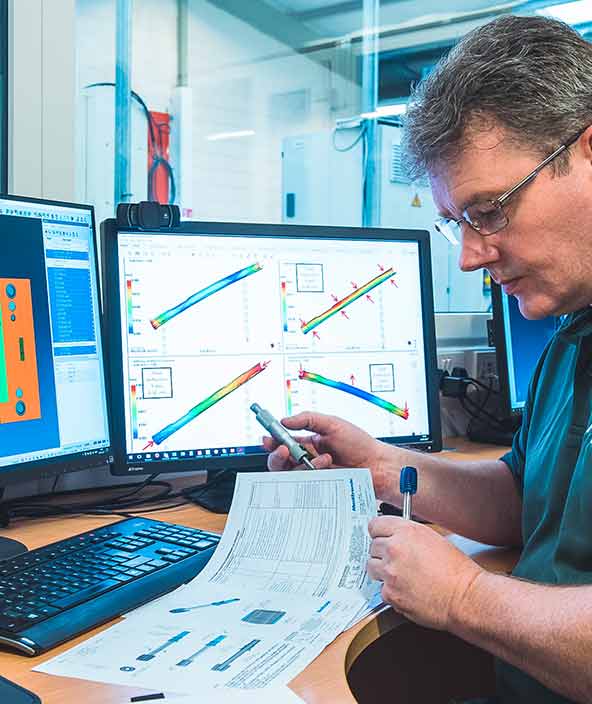

Bringing accuracy to mould and die design and manufacturing

Put data to work to improve accuracy in mould and die design for better quality production.

To be competitive in the tooling, mould and die industry, quality and efficiency are key. Hexagon’s solutions streamline the mould and die development process from design to manufacturing, ensuring accurate manufacturing for both tooling and end products.

Overview

Mould and die is a highly efficient way to manufacture parts in plastics, metal and a number of other materials. Whether using a mould or a die, accurate design and production of the tooling is essential to ensure the quality of the final part. Toolmakers, die makers and mould-makers in every industry therefore rely on specialist mould and die design and manufacturing solutions to ensure efficient production.

Hexagon’s CAD CAM portfolio features dedicated solutions for the 3D design of plastic injection moulds and progressive dies, plastic injection moulding flow simulation, sheet metal stamping, surface and solid modelling and multi-axis machining. They enable mould and die manufacturers to better control every stage of the process, reducing rework and costly production errors and ensuring delivery of projects on time and budget.

Explore

$ProductName

$SustainabilityImpactLabel

$SustainabilityCTABandHeadingLabel

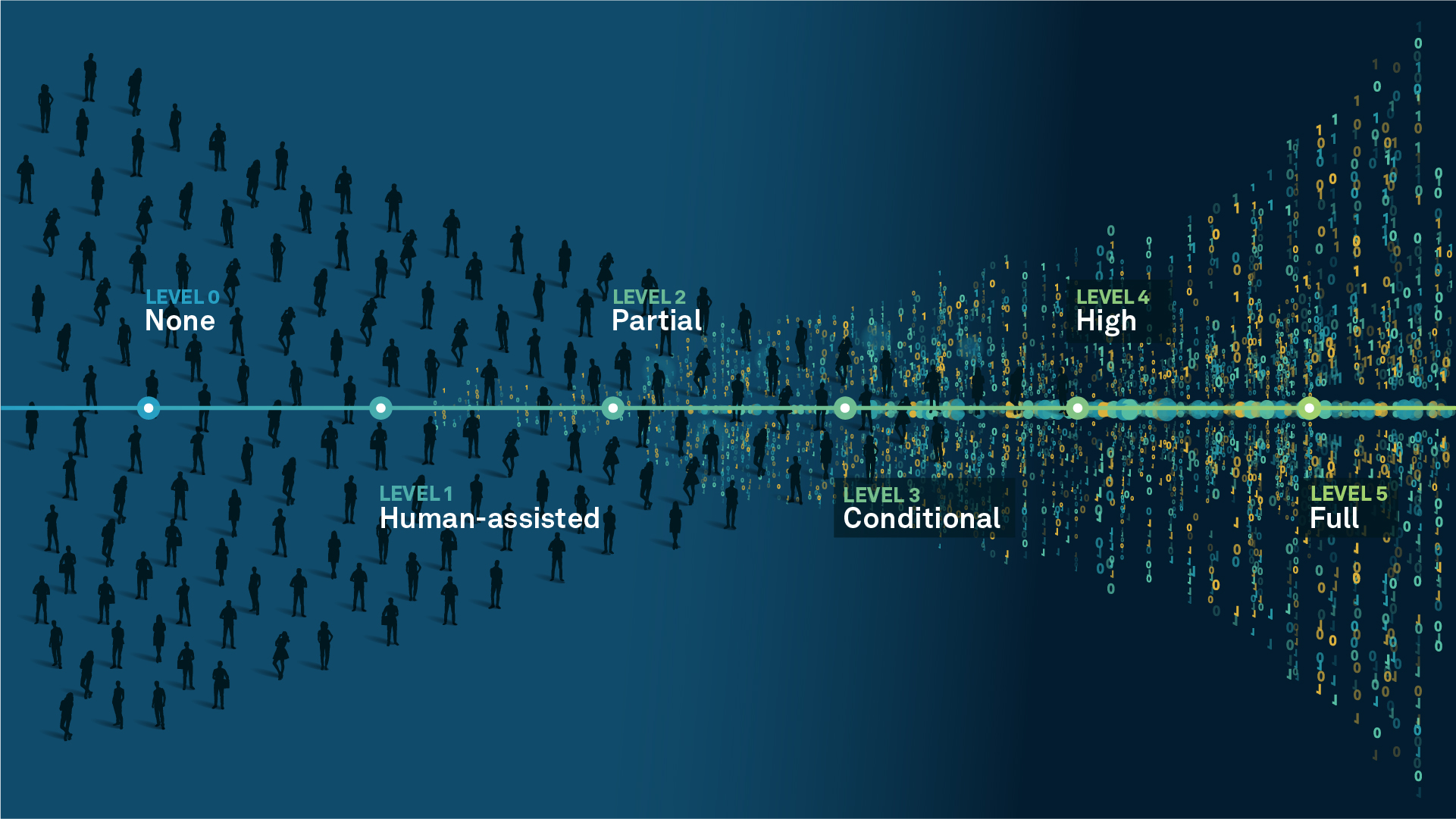

We’re climbing the automation curve

Our transition to Intelligent automation is accelerating. Ultimately, our innovations will give rise to new technologies and applications - many of which we’ve yet to imagine. Today, every Hexagon solution is mapped and tagged according to its level of automation, so customers can clearly track our progress towards the freedom of autonomy.

Human-driven

All tasks completed by human labour; no data is leveraged across the operation.

Human-assisted

Labour is primarily conducted by a human workforce. Some functions have been automated to simplify control.

Partial automation

Some tasks are automated for short periods of time, accompanied by occasional human intervention.

Conditional automation

Human workforce is used for intervention as autonomous operations begin to increase productivity.

Highly autonomous

Autonomous systems complete required tasks within specific bounds, unleashing data and building smart digital realities.

Full autonomy

A smart digital reality™ enables autonomous systems to complete all tasks without human intervention.

Land

Products that make an environmental impact in forest monitoring, material reusability, farming or water usage.

Air

Products that make an environmental impact in renewable energy, noise pollution elimination and e-mobility.

Water

Products that make an environmental impact in saving our oceans, reducing pollution and increasing access to clean water.