Material modelling

Empowering materials autonomy to drive digital transformation and accelerate sustainable innovation.

Empowered by synergistic integrated computational material engineering (ICME) and modelling, data management and artificial intelligence capabilities, Hexagon’s materials autonomy solutions ensure the ability to meet the evolving needs of new markets and drive sustainable product design.

-

Use

-

Manage

-

Design

-

Manufacture

-

Digitalise

Sustainable product design

Sustainability requires true innovation in the connection of materials, manufacturing and product design.

Hexagon’s integrated computational materials engineering (ICME) tools serve as a low-cost, high-speed solution for minimising the time, cost and risk associated with part design, material development/selection, processing optimisation, performance simulation and production scaling.

Materials lifecycle data management

Accelerate sustainable innovation with reliable access to critical materials information. Hexagon’s class-leading material data management solution ensures a ‘single source of truth’ for the entire organisation, including full-lifecycle data traceability, regulatory compliance and certification.

An enterprise-calibre data management solution ensures engineers have quick and easy access to critical materials information, thus maximising productivity and innovation. Additionally, access to commercial material databanks and advanced AI technologies ensure Hexagon’s solution is both well-stocked with valuable data and well-equipped to handle both current and future needs.

Materials by design

Material engineering is largely an empirical process, requiring accurate information, experimentation and optimisation. Hexagon’s class-leading material modelling capabilities digitalise the development process and provide an end-to-end solution for accelerating materials innovations.

Hexagon’s digital transformation solutions support the development of material digital twins, or ‘material cards’, leading to a reduction in the time, cost and risk associated with development. Additionally, these material cards can be integrated into both internal and customer multiphysics workflows, ensuring that simulations take into account the nuances of complex material systems.

Smart manufacturing of sustainable products

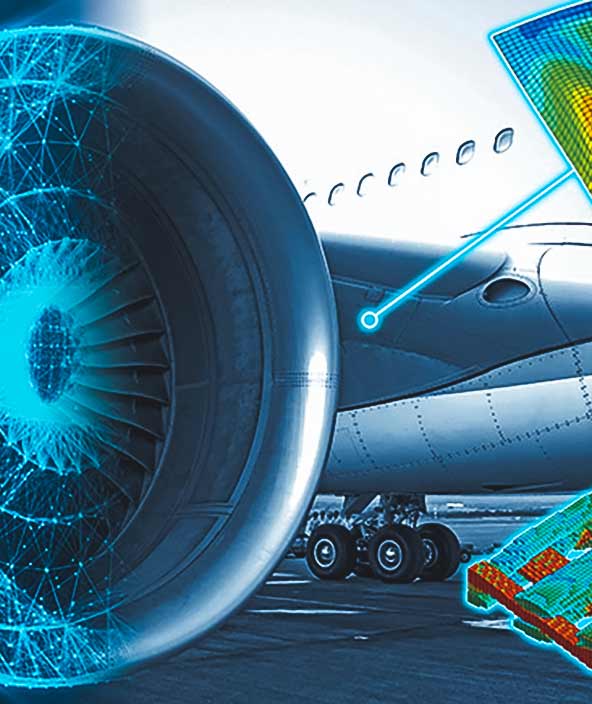

Design and manufacturing innovation aids sustainable product development and supports a circular economy. Simulating and optimising variables is also key to maximising product performance. That said, even a perfect material model is limited if manufacturing creates defects like voids, wrinkles or residual stresses.

Hexagon’s materials solutions can reveal the effects of manufacturing processes and defects, enhancing accuracy in part performance predictions and allowing engineers to optimise process variables, material selection and/or part design.

For additive, process simulations optimise the printing strategy, minimising warpage and enabling ‘first time right’ prints. For continuous fibre composites (CFRPs), simulating fibre and curing defects enables optimal material usage and accurate part performance predictions. For injection moulded parts like short fibre composites (SFRPs), simulation as a means to optimise gate location positively affects efficiencies and part performance.

The age of digitalisation

To be more competitive and successful in the digital era, a seamless digital transformation journey is critical. Hexagon’s materials autonomy solutions are a vector of innovation supporting efficiency within both design and manufacturing at scale. Leveraging technologies such as cloud computing and artificial intelligence (AI), Hexagon’s materials solutions enable the realisation of efficiencies via the autonomous processing of vast amounts of material data, providing reliable access to critical information and bridging gaps where data may be lacking.

Materials autonomy turns data into innovative power, integrating material modelling and data management synergistically to explore the link between design and manufacturing. Advanced, intelligent and scalable, these material digital twins help to accelerate the innovation of sustainable products, as well as set new standards of excellence.

Explore

$ProductName

$SustainabilityImpactLabel

$SustainabilityCTABandHeadingLabel

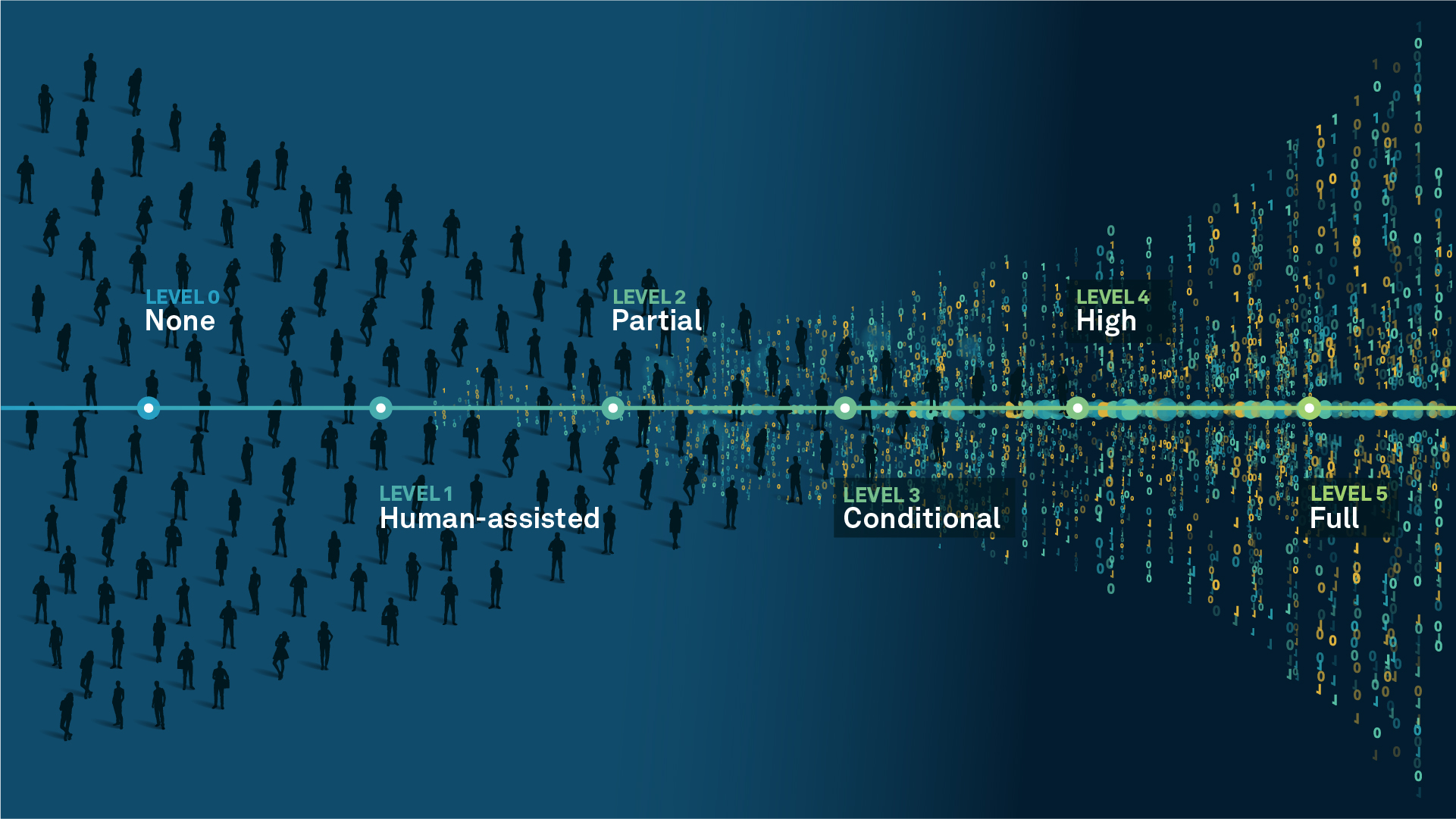

We’re climbing the automation curve

Our transition to Intelligent automation is accelerating. Ultimately, our innovations will give rise to new technologies and applications - many of which we’ve yet to imagine. Today, every Hexagon solution is mapped and tagged according to its level of automation, so customers can clearly track our progress towards the freedom of autonomy.

Human-driven

All tasks completed by human labour; no data is leveraged across the operation.

Human-assisted

Labour is primarily conducted by a human workforce. Some functions have been automated to simplify control.

Partial automation

Some tasks are automated for short periods of time, accompanied by occasional human intervention.

Conditional automation

Human workforce is used for intervention as autonomous operations begin to increase productivity.

Highly autonomous

Autonomous systems complete required tasks within specific bounds, unleashing data and building smart digital realities.

Full autonomy

A smart digital reality™ enables autonomous systems to complete all tasks without human intervention.

Land

Products that make an environmental impact in forest monitoring, material reusability, farming or water usage.

Air

Products that make an environmental impact in renewable energy, noise pollution elimination and e-mobility.

Water

Products that make an environmental impact in saving our oceans, reducing pollution and increasing access to clean water.