Hexagon’s approach and value in the manufacturing ecosystem

What if you could view any product from concept to customer, through service life to recycling, while minimising waste?

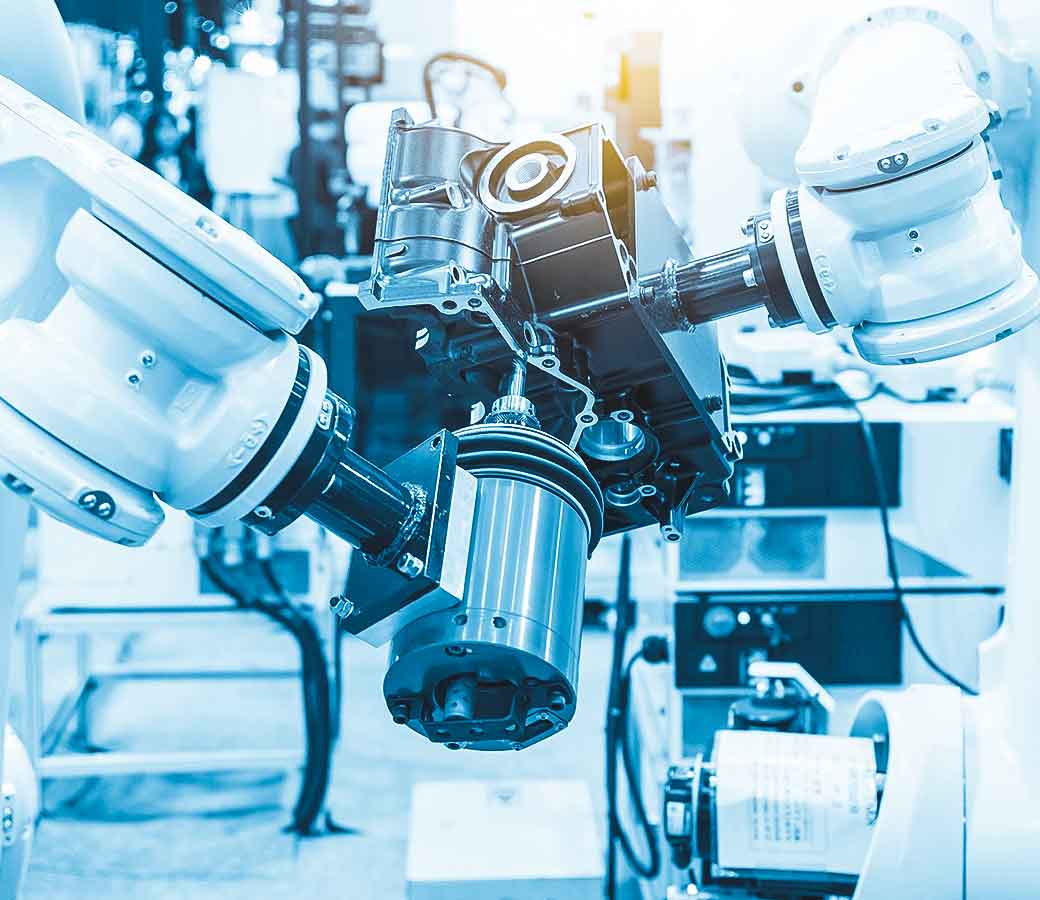

A smarter approach to manufacturing

Hexagon’s manufacturing technology solutions create a digital thread throughout all manufacturing processes that provide insights to help you continuously improve time-to-market, quality and productivity, enabling the entire ecosystem to connect, analyse , learn and improve over time. Hexagon’s approach can help you:

- Unlock value from data you already have but don’t use — Every factory generates a vast amount of data throughout the entire manufacturing process. We digitalise the manufacturing ecosystem, putting this data to work to connect entire workflows and build autonomy and intelligence into every process.

- Change incrementally, improve exponentially — Hexagon recognises that digital transformation is a process, not a single act. Even incremental steps in digitalisation can vastly improve quality while reducing costs and waste.

- Create a Smart Digital Reality — Hexagon’s approach is to create a Smart Digital Reality — a living digital twin of the manufacturing process, so the entire product lifecycle can be simulated, visualised and optimised in real time.

What's holding you back?

- Siloed, inaccessible or static data

- Limited data-sharing or connectivity across the entire asset and product lifecycle and between departments, OEMs and the supply network

- Increasingly shorter product lifecycles

- Maintaining quality at lower price thresholds

- Slow response time and lack of agility to supply/demand interruptions

- No resilience plan for physical and digital assets