Machine Control and Automation

Solutions to increase accuracy, productivity, and uptime on-site.

Hexagon’s machine control and automation technology provides the construction professional with simplified and connected solutions for increasing staff productivity on site and unifying design data for seamless workflows in order to keep margin gains and generate profits.

-

Overview

-

Software

-

Connectivity & Data Management

-

Construction survey

-

Safety Awareness

Digitise your construction site with machine control and automation solutions.

Hexagon offers a complete portfolio of solutions with a unified hardware platform with common software interface across our machine control and automation portfolio. Interchangeable between several heavy construction machines, the Leica MCP80 control unit integrates into the common software platform, Leica MC1, while Leica ConX, the cloud-based and user-friendly productivity platform for increased project efficiency, rounds off Leica Geosystems’ goal to achieve a digitised construction site.

Consolidating all machine applications, Leica MC1 is the one-for-all software solution platform to guide and automate all heavy construction machines.

Leica MC1 is carried by the rugged hardware platform, the Leica MCP80 panel and MDS Series docking station, ensuring an interchangeable panel between machines on a job site.

Reduce costs, increase productivity

Consistency in software design throughout all heavy machine control and automation applications reduces our customers’ training efforts and optimises their learning curve. The same software platform can be used with different sensor configurations, which improves scalability and training.

Simplified work progress

An intuitive graphical interface with custom-centred design supports our customers in getting their job done faster and more precise.

Improved Data handling

MC1 software simplifies design data handling and is open to all standard design data types, enabling a flexible dataflow to support common workflows on a job site.

Leica ConX is a cloud-based collaboration tool allows you to efficiently manage all your connected construction projects and to share job-related data with all stakeholders. Visualise and validate localised reference models, survey data and constructed data with powerful analysis tools for monitoring and reporting site productivity.

Minimise operator downtime with remote real-time communication between office and machine for troubleshooting, on-the-fly training and setup without travel costs and delays.

iCON office is an application that can import and export data formats that have become de facto industry standards as well as many data formats that are used only in specific regions.

Offers a seamless data flow from office to field through an API integration to Leica ConX. Available machines and their locations can be displayed in iCON office. The integration also allows sharing of design and as-built data directly between iCON office and equipment on site.

Invest in the solution you need today and have the flexibility to expand your product portfolio based on your future needs tomorrow. Maximise your investment with flexible hardware and software solutions that allow you to carry out critical positioning tasks with confidence. These on-the-ground solutions not only increase your efficiency, but your peace of mind as well.

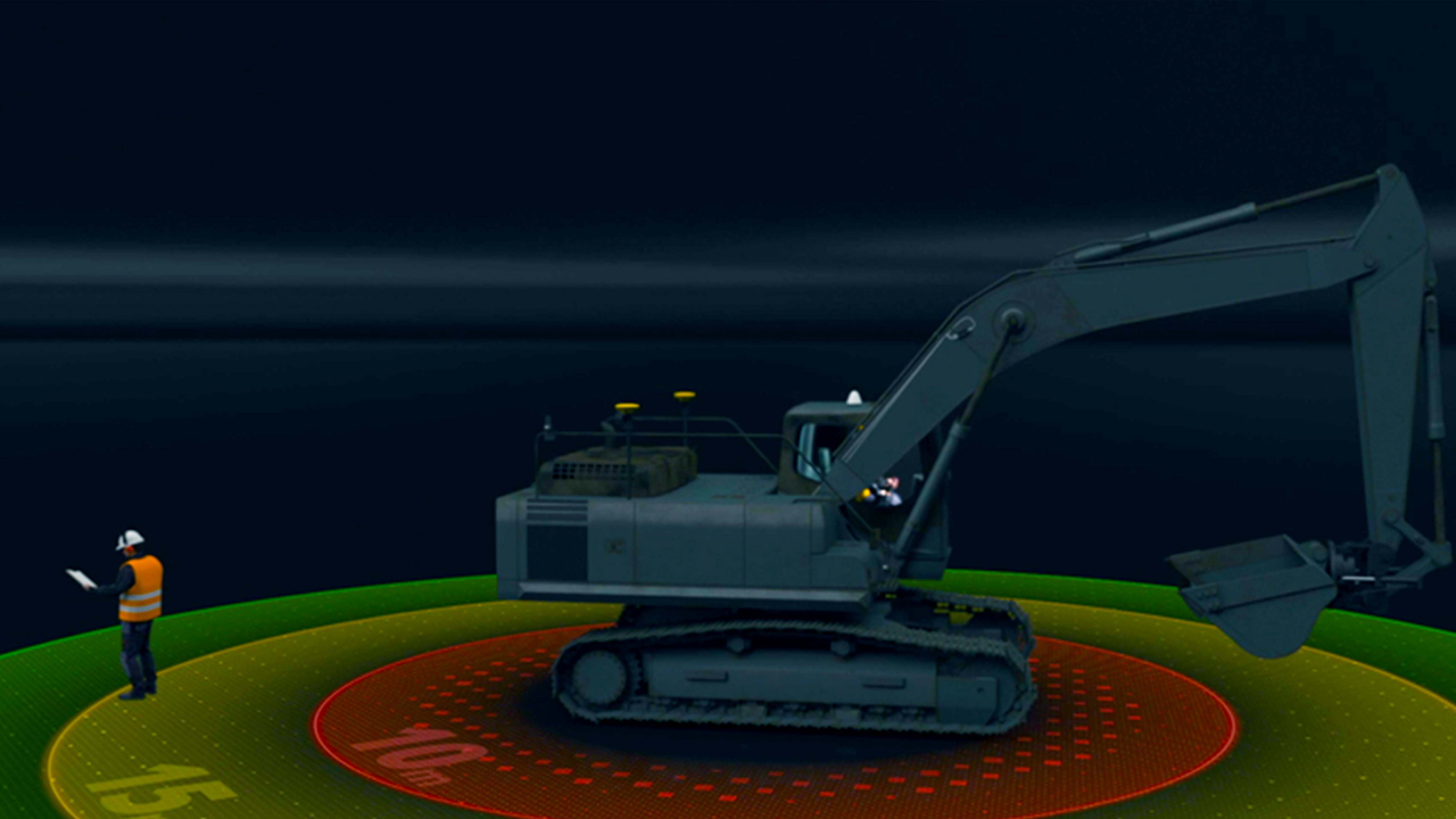

Modular Safety Awareness Solutions to increase worker safety awareness and visibility between workers and machine operators to prevent machine-to-people, machine-to-machine, and machine-to-objects collisions.

Personal Alert, PA10

Leica PA10 combines a tag worn by personnel moving around on foot that can communicate with a stand-alone panel inside machines or vehicles on sites.

Personal Alert, PA80

Leica PA80 combines the tag worn by personnel moving around on foot and the MC1 machine control solution.

Collision Avoidance, CAS

CAS can be added to both PA10 and PA80 solutions.With a CAS system, we can “talk” to other machines over 800 m away and calculate potential collisions from much further distance than the PA anchors.

Tracking and Reporting

Reporting and documentation can help your Health and Safety organisation to learn about behavior and increase safety, save costs, decrease downtime, and improve productivity.

Explore

$ProductName

$SustainabilityImpactLabel

$SustainabilityCTABandHeadingLabel

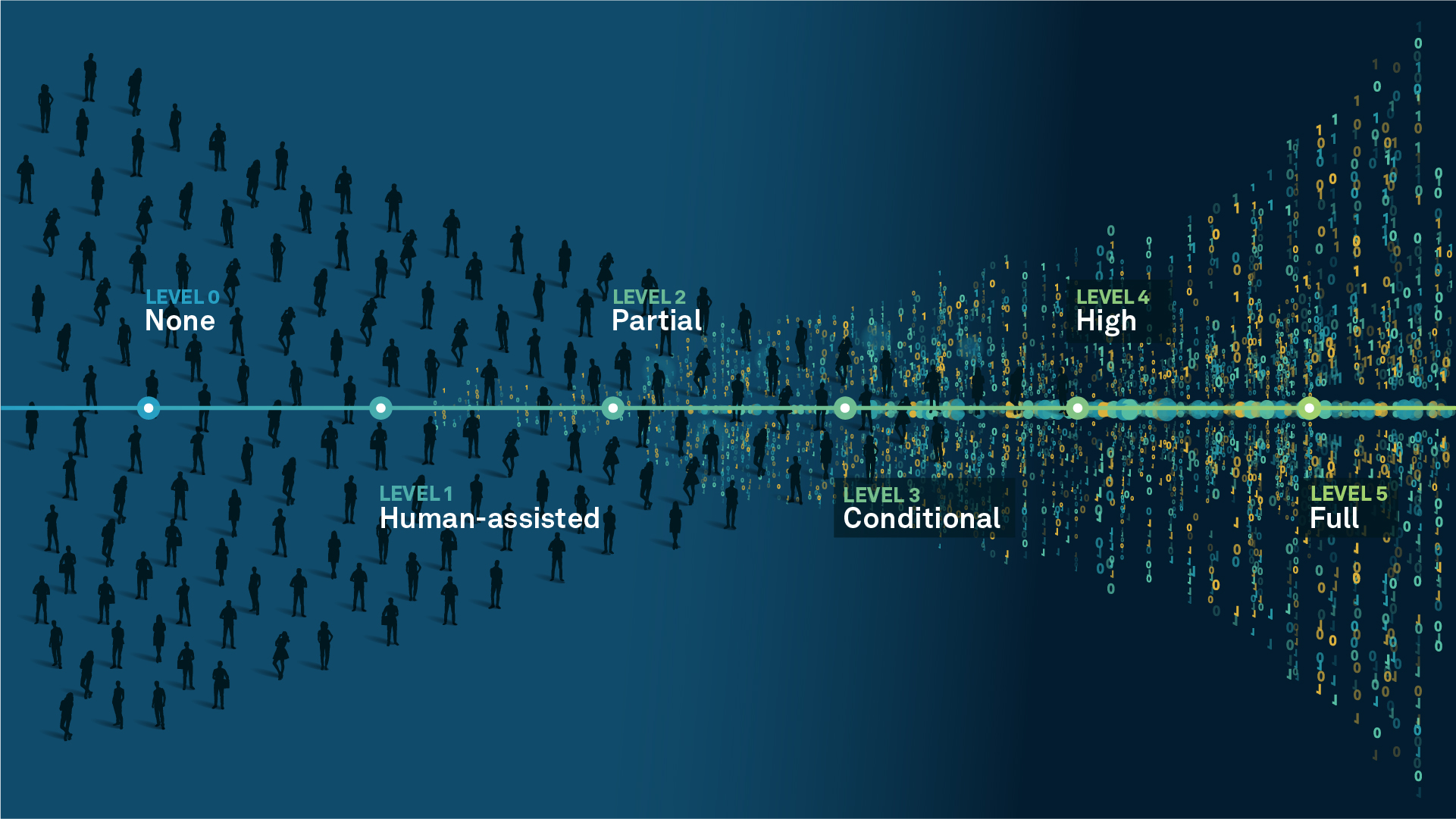

We’re climbing the automation curve

Our transition to Intelligent automation is accelerating. Ultimately, our innovations will give rise to new technologies and applications - many of which we’ve yet to imagine. Today, every Hexagon solution is mapped and tagged according to its level of automation, so customers can clearly track our progress towards the freedom of autonomy.

Human-driven

All tasks completed by human labour; no data is leveraged across the operation.

Human-assisted

Labour is primarily conducted by a human workforce. Some functions have been automated to simplify control.

Partial automation

Some tasks are automated for short periods of time, accompanied by occasional human intervention.

Conditional automation

Human workforce is used for intervention as autonomous operations begin to increase productivity.

Highly autonomous

Autonomous systems complete required tasks within specific bounds, unleashing data and building smart digital realities.

Full autonomy

A smart digital reality™ enables autonomous systems to complete all tasks without human intervention.

Land

Products that make an environmental impact in forest monitoring, material reusability, farming or water usage.

Air

Products that make an environmental impact in renewable energy, noise pollution elimination and e-mobility.

Water

Products that make an environmental impact in saving our oceans, reducing pollution and increasing access to clean water.