Grade Control

Standardise and integrate the grade control process by ensuring tasks are completed sequentially.

Standardise your mine’s grade control into an auditable process

Hexagon ensures your grade control process is repeatable, auditable, and integrated into daily operational processes.

Hexagon’s mine planning software allows you to integrate workflows into a mine's daily operational processes to optimise the recovery of the mineral resource. Standardising the entire grade control process ensures that tasks are completed sequentially with no missed steps.

Overview

Grade control is key to a mine’s downstream processes and integral to optimising recovery of its primary resource. Determining where each material should be routed depends on having all the information in front of you.

Hexagon software answers this need by consolidating and streamlining processes to manage blasthole survey, geology and grades using a database and quality assurance/quality control (QAQC) workflow.

Once blasthole data is approved, a rapid, standardised and auditable tool executes the block model interpolation process using highly customisable functions assembled in a workflow. Dig blocks are defined and materials routed to optimise accounting for dilution, grade and other geological factors.

After dig blocks are optimised, a click of a button sends polygons to fleet supervisors, surveyors and other stakeholders. When the shovel starts mining the routed material, Hexagon software reports daily shovel progress and available muck.

Explore

$ProductName

$SustainabilityImpactLabel

$SustainabilityCTABandHeadingLabel

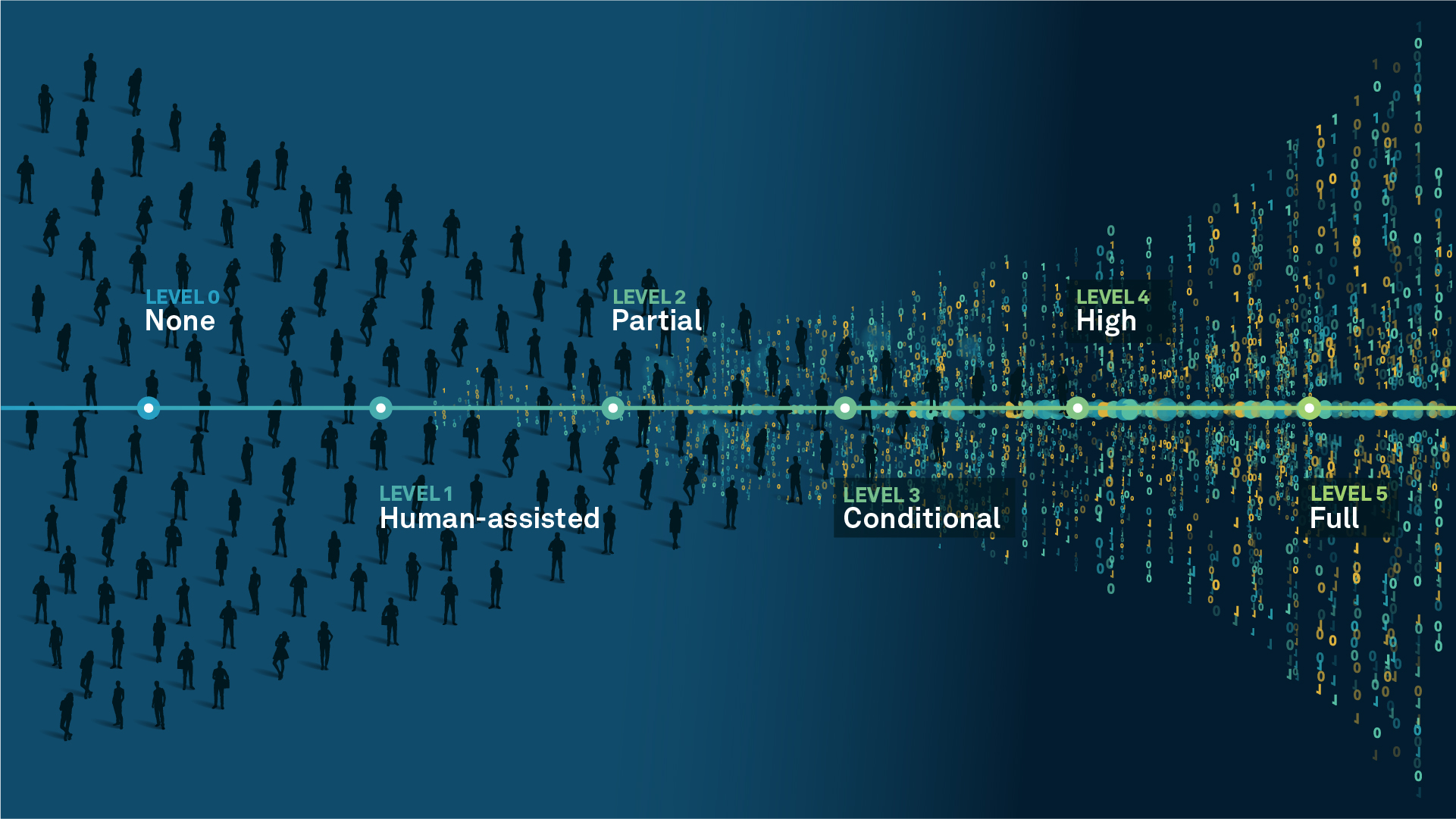

We’re climbing the automation curve

Our transition to Intelligent automation is accelerating. Ultimately, our innovations will give rise to new technologies and applications - many of which we’ve yet to imagine. Today, every Hexagon solution is mapped and tagged according to its level of automation, so customers can clearly track our progress towards the freedom of autonomy.

Human-driven

All tasks completed by human labour; no data is leveraged across the operation.

Human-assisted

Labour is primarily conducted by a human workforce. Some functions have been automated to simplify control.

Partial automation

Some tasks are automated for short periods of time, accompanied by occasional human intervention.

Conditional automation

Human workforce is used for intervention as autonomous operations begin to increase productivity.

Highly autonomous

Autonomous systems complete required tasks within specific bounds, unleashing data and building smart digital realities.

Full autonomy

A smart digital reality™ enables autonomous systems to complete all tasks without human intervention.

Land

Products that make an environmental impact in forest monitoring, material reusability, farming or water usage.

Air

Products that make an environmental impact in renewable energy, noise pollution elimination and e-mobility.

Water

Products that make an environmental impact in saving our oceans, reducing pollution and increasing access to clean water.