Keeping oil-hydraulic component supplier’s production cell at full flow

3B Fluid Power - Italy

Contact us

Formed in 2002, 3B FLUID POWER SRL started as a contract inspection firm, working mainly with aerodynamic components. Gradually the company has moved into other industries, and now operates across the agricultural, aerospace and automotive sectors as well. The products manufactured at the site in Novellara, Italy, are primarily oil-hydraulic control units in cast iron or aluminium, but the company also produces some plastic parts such as oil filters.

In the years since its foundation, 3B FLUID POWER has been driven by a commitment to meet the needs of its customers – both in terms of delivery and in terms of quality.

As the business scaled up, investing in new technologies to optimise their production workflows became a real priority to enable continued growth. The company philosophy was to implement new systems capable of handling greater volumes of products, enabling it to gain ground when customers’ requirements increased.

Today, measuring systems play an important role in the production process, enabling 3B FLUID POWER to reach a high standard of quality in their products. But at implementation, the challenge was to achieve this quality as well as saving time and costs. The strategy was to integrate a new coordinate measuring machine (CMM) directly into the production workflow to help reduce inspection times, but also to achieve better accuracies at the same time, and this meant investing in a new and more efficient machine.

It was these drivers, and the need to increase the sampling rate of measurement within the machining cycle for optimal quality, that led the company to purchase a TIGO SF from Hexagon Manufacturing Intelligence. 3B FLUID POWER was looking for a measuring machine suitable for a manufacturing environment and approached Hexagon as a consultant to identify the best solution for their plant. After assessing the needs of the production line, the two companies agreed that a TIGO SF shop-floor CMM would be the ideal choice.

“We opted for a TIGO SF CMM because this machine has characteristics that make it suitable for operations in a shop-floor environment,” says Andrea Barani, General Manager at 3B FLUID POWER.

Not only is the TIGO SF a fully-protected CMM designed specifically for the shop floor, but it is also supplied ready for integration directly within the production workflow. This in-line measurement potential was a big deciding factor for 3B FLUID POWER as it enabled the company to make more accurate measurements than previously, while also moving towards more automated processes.

3B FLUID POWER typically produces components such as housings for small gearboxes and fluid hydraulic equipment, so its part tolerances are usually in the region of 10 microns. This requires precision machining equipment and consequently accurate dimensional inspection. The TIGO SF was installed in a cell with the support of Hexagon technicians.

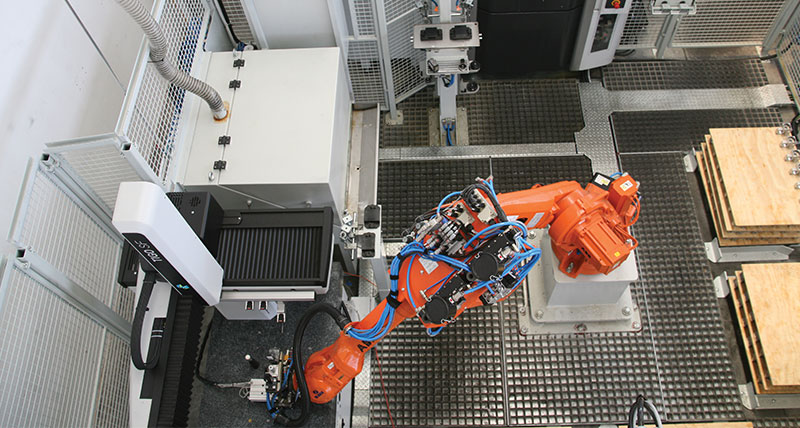

Application engineers from the measurement and manufacturing equipment company provided extensive assistance to 3B FLUID POWER, programming all the parts that the cell will manage and optimising measuring cycles to ensure the new machine was up and running quickly. The cell is an automated part of the production cycle, producing micro gear motors that start life as raw aluminium die-cast parts that are loaded on to the machining centre by a robot. After machining, the part is taken by the robot, deburred and washed before loading on to the new TIGO SF for critical dimensions to be verified.

Prior to the automated cell’s installation, measurements were performed in a separate quality control room. The new CMM’s integration into this fully-automatic manufacturing cell allows 3B FLUID POWER to maintain a higher sampling rate in part inspection, as well as facilitating significant productivity gains that have contributed to the company trebling its turnover within just a few years.

“We have increased sampling from 10% of products measured daily to 50% and all the inspection is performed without slowing down the work cycle of the machine. The whole process is automated, so we can work 24 hours a day, 7 days a week,” continues Barani. “The installation of this automatic cell for machining, coupled with this kind of dimensional inspection has certainly meant a quantum leap in quality for 3B.”

In the years since its foundation, 3B FLUID POWER has been driven by a commitment to meet the needs of its customers – both in terms of delivery and in terms of quality.

As the business scaled up, investing in new technologies to optimise their production workflows became a real priority to enable continued growth. The company philosophy was to implement new systems capable of handling greater volumes of products, enabling it to gain ground when customers’ requirements increased.

Today, measuring systems play an important role in the production process, enabling 3B FLUID POWER to reach a high standard of quality in their products. But at implementation, the challenge was to achieve this quality as well as saving time and costs. The strategy was to integrate a new coordinate measuring machine (CMM) directly into the production workflow to help reduce inspection times, but also to achieve better accuracies at the same time, and this meant investing in a new and more efficient machine.

It was these drivers, and the need to increase the sampling rate of measurement within the machining cycle for optimal quality, that led the company to purchase a TIGO SF from Hexagon Manufacturing Intelligence. 3B FLUID POWER was looking for a measuring machine suitable for a manufacturing environment and approached Hexagon as a consultant to identify the best solution for their plant. After assessing the needs of the production line, the two companies agreed that a TIGO SF shop-floor CMM would be the ideal choice.

“We opted for a TIGO SF CMM because this machine has characteristics that make it suitable for operations in a shop-floor environment,” says Andrea Barani, General Manager at 3B FLUID POWER.

Not only is the TIGO SF a fully-protected CMM designed specifically for the shop floor, but it is also supplied ready for integration directly within the production workflow. This in-line measurement potential was a big deciding factor for 3B FLUID POWER as it enabled the company to make more accurate measurements than previously, while also moving towards more automated processes.

3B FLUID POWER typically produces components such as housings for small gearboxes and fluid hydraulic equipment, so its part tolerances are usually in the region of 10 microns. This requires precision machining equipment and consequently accurate dimensional inspection. The TIGO SF was installed in a cell with the support of Hexagon technicians.

Application engineers from the measurement and manufacturing equipment company provided extensive assistance to 3B FLUID POWER, programming all the parts that the cell will manage and optimising measuring cycles to ensure the new machine was up and running quickly. The cell is an automated part of the production cycle, producing micro gear motors that start life as raw aluminium die-cast parts that are loaded on to the machining centre by a robot. After machining, the part is taken by the robot, deburred and washed before loading on to the new TIGO SF for critical dimensions to be verified.

Prior to the automated cell’s installation, measurements were performed in a separate quality control room. The new CMM’s integration into this fully-automatic manufacturing cell allows 3B FLUID POWER to maintain a higher sampling rate in part inspection, as well as facilitating significant productivity gains that have contributed to the company trebling its turnover within just a few years.

“We have increased sampling from 10% of products measured daily to 50% and all the inspection is performed without slowing down the work cycle of the machine. The whole process is automated, so we can work 24 hours a day, 7 days a week,” continues Barani. “The installation of this automatic cell for machining, coupled with this kind of dimensional inspection has certainly meant a quantum leap in quality for 3B.”