Leitz Reference Flexibility

アプリケーションの適応性を最大限に高めた、厳しい公差部品の高精度測定

アプリケーションの柔軟性を備えた高い測定精度が必要ですか?

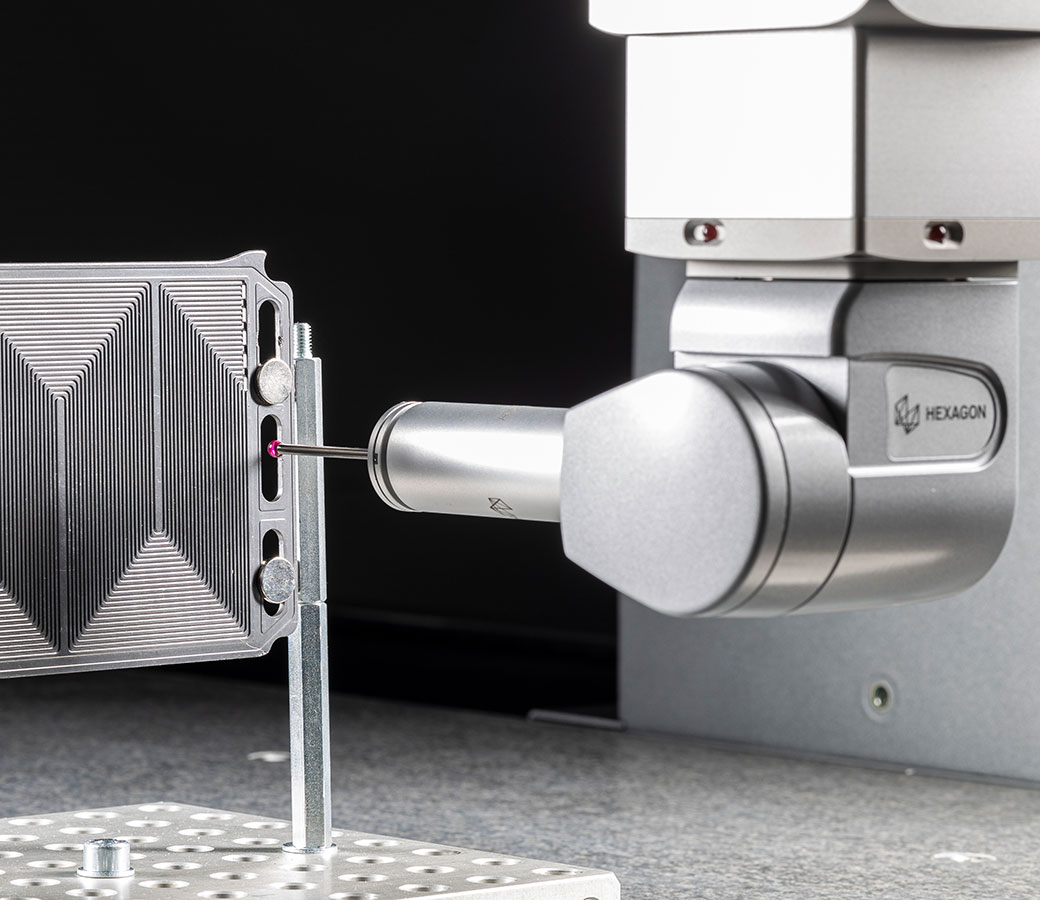

スマートセンサー自動化は、測定サイクルの効率を向上します。

詳しい情報をご希望ですか?

Leitz Reference Flexible は Precision モデルの構成に基づいて構築されているため、より困難な測定作業へのマシンの適応性を高め、サイクルタイムを削減する能力があります。

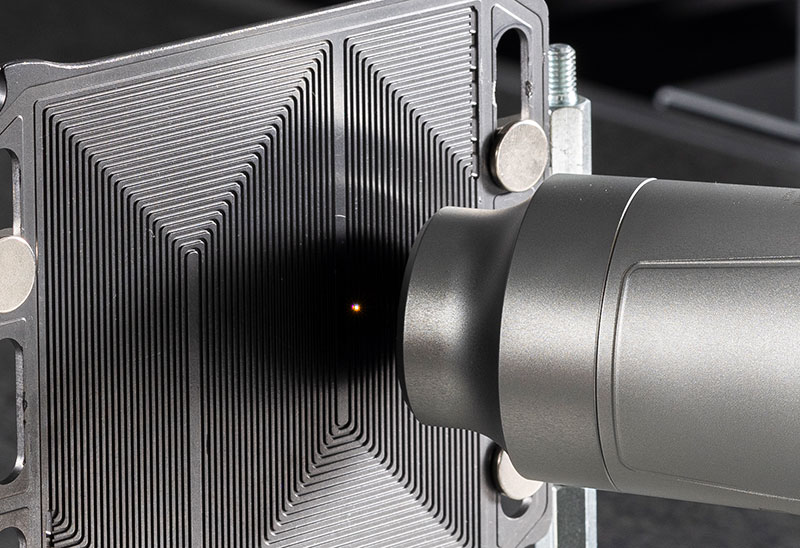

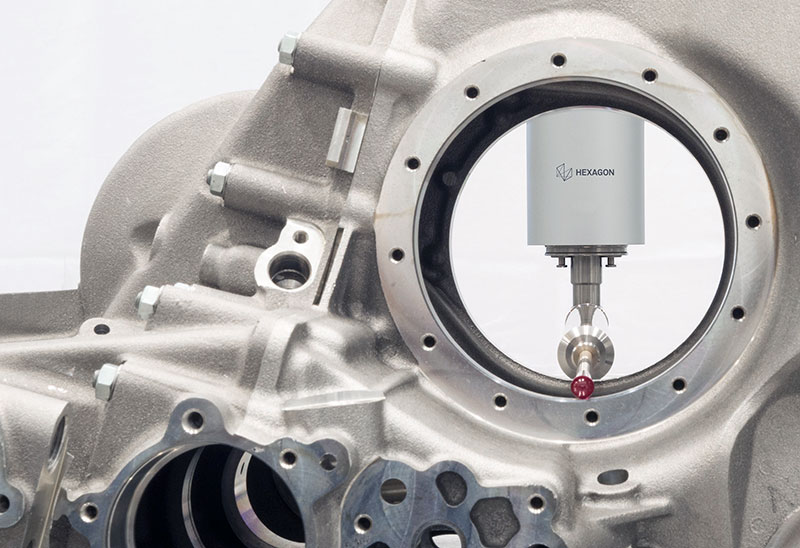

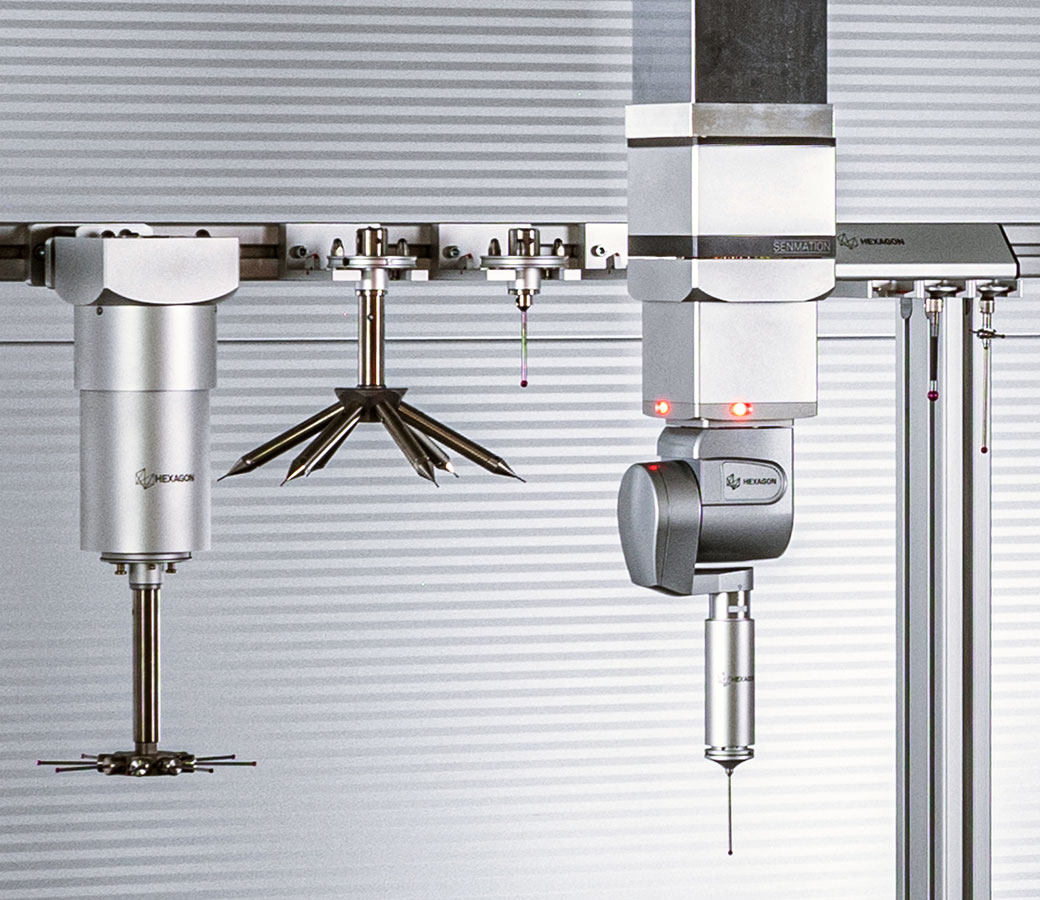

CMM には、どのような角度でも測定できる関節式プローブヘッドが搭載され、複雑な 3D 部品形状へのアクセスを可能にします。さらに SENMATION センサー自動化システムは、複数の部品やアプリケーションに対応するために、1 回の測定ルーチン内にさまざまな触覚および光学センサーをシームレスに統合し、測定の柔軟性を高めます。

主な活用現場

アプリケーションの課題

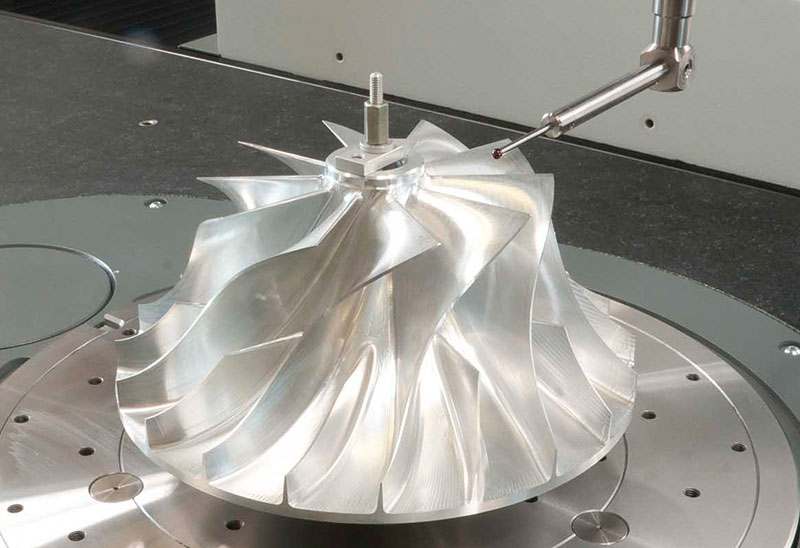

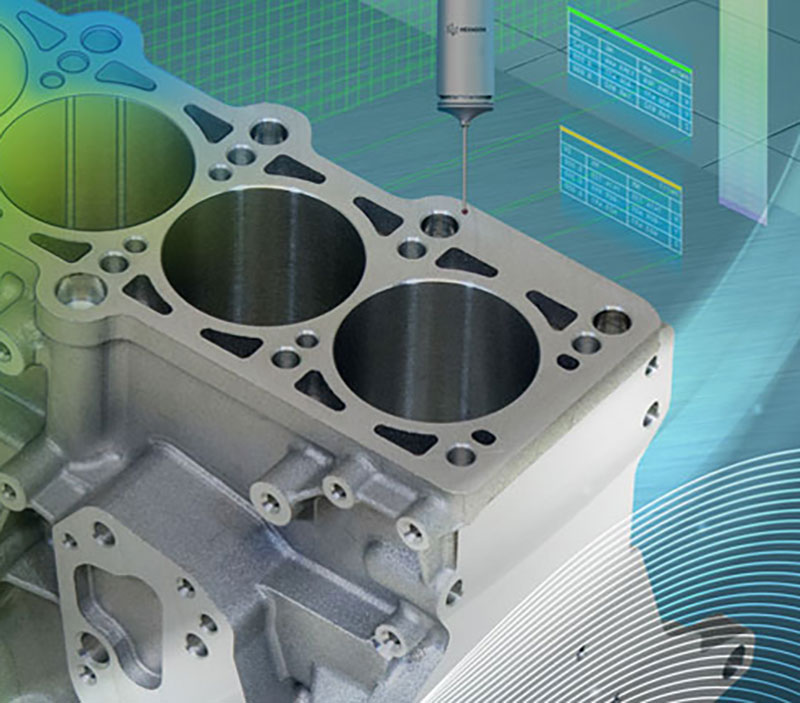

サイクルタイムを短縮した最も複雑な形状の高精度測定

- さまざまな測定要件を持つ多種多様な部品

- 複雑な 3D 形状と厳しい公差

- 部品周辺のアクセスしにくい空間定位における機能的なサイズと形状特徴

- さまざまな材料の種類と表面特性

Leitz Reference Flexible の利点

- 高いスループットと汎用性のあるマルチセンサー測定

- 電動インデックスプローブヘッドで複雑なワークピースにも容易にアクセス

- SENMATION センサー自動システムにより、アプリケーションの適応性を拡張し、将来に対応

- クロマチック白色光、干渉計、レーザースキャンセンサーによる非接触測定

- 光学または触覚式同時 4 軸スキャンとロータリーテーブルの組み合わせ

Leitz Reference Flexible の構成

基本システム

個別のアプリケーションニーズに合わせてカスタマイズされたオプション

Leitz Reference Flexible の各機器は、アプリケーションニーズに最も適したオプションによって、機能をさらにカスタマイズすることができます。CMM 初期構成時にさまざまなオプションを選択するか、後日、ほとんどのオプションを修理中の機械にアップグレードとして設定することができます。

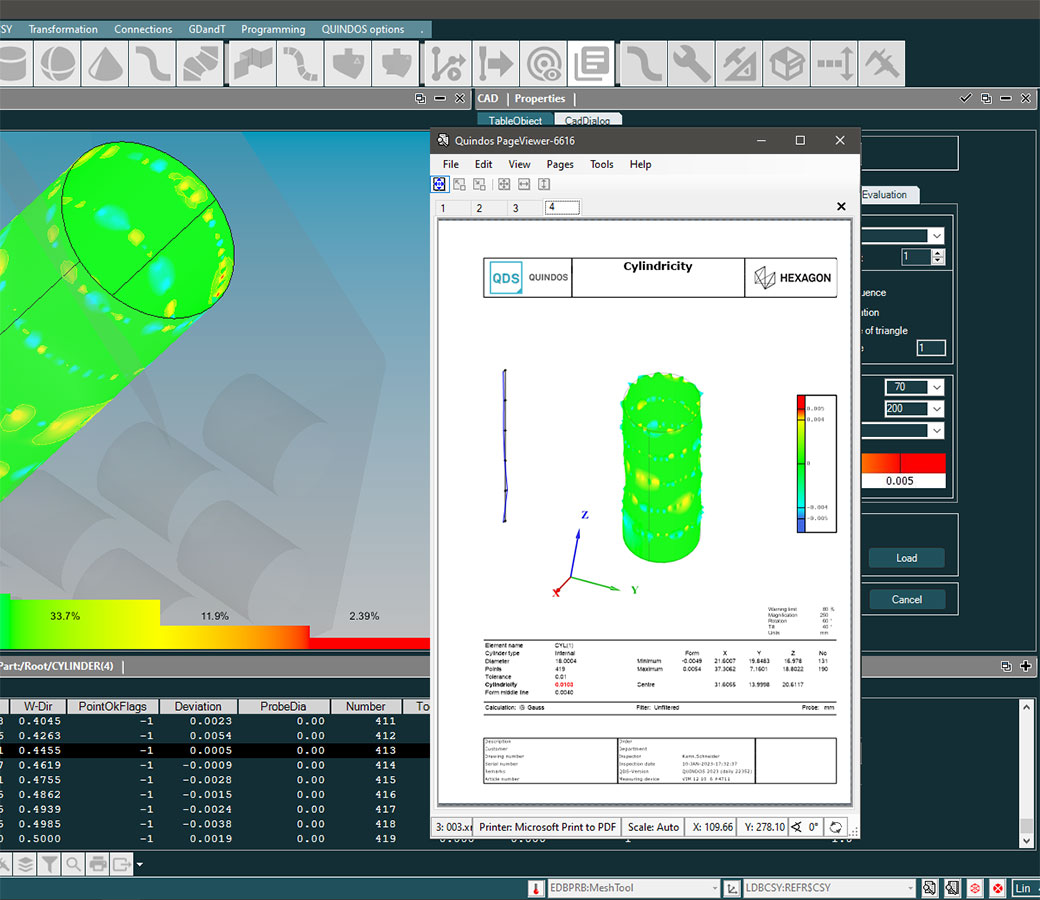

CAD ++ では最も複雑な部品の測定が可能です。CAD の全機能が搭載されており、薄肉のシートメタル、プラスチック、ブレード、ダイ、金型など、複雑なコンター表面も測定できます。CAD++ は多数のスキャン装置とアプリケーションをサポートし、大量のデータを管理するためのアルゴリズムを備えています。CAD とリンクできるため、追随を許さないスピードと精度で測定結果をモデルと直接比較できます。機能が豊富で使いやすい製品です。

Leitz Reference Flexible モデルは、広範囲の分野のアプリケーションで活用できるように、追加のプローブヘッドとセンサーを装備することができます。

HP-S-X5-HD

高精度と高い再現性で、最も厳しい公差でスキャンするための固定触覚プローブヘッド。また、 Profiler R の粗さセンサーを運ぶためにも使用できます。

HP-OW 白色光センサー

最も困難な表面仕上げを含む、ほぼすべての材料に対応する高精度光学センサー。

HP-O 光学センサー

最も厳しい公差に光学干渉法距離測定を使用して、超高速で正確な測定を実施。

PROFILER R

同じ測定設定で表面評価に対応する表面および面粗度センサー。

Leitz Reference CMM 用のロータリーテーブルは、内蔵式または卓上型として利用でき、測定部品へのアクセスを強化して手作業を不要とし、回転対称部品などを測定する際、同時 4 軸スキャンに使用できます。

Leitz Reference マシンは、最も困難な要求を満たすように設計されています。さらに高い正確度と精度要件に対しては、2 つの追加の精度オプションから選択し、より優れた測定結果を得ることができます。

Leitz Reference Flexible モデルは、あらゆるアプリケーションで最大に活用できるように、さまざまなオプションを装備することができます。

XTオプション

このオプションは、過酷な環境や広範な温度範囲でも信頼性が高く正確な CMM 測定を可能にします。

PULSE リアルタイム環境モニタリング

このシステムは、測定結果に影響を与える可能性のある温度、湿度、振動、気圧、光度の変化をユーザーに通知することで測定データの完全性を保証します。

QUINDOS 特殊形状用

QUINDOS は最も困難な計測プロジェクトに対応し、ギヤ、歯切りツール、ブレード、その他の複雑なアプリケーションを含む、規則的な形状、自由形状、特殊形状の測定を取り扱う際、頼りになるソリューションです。

機能と利点

Leitz Reference CMM は、確実性と信頼性を与える高度な設計原則に基づいています。高品質な部品と最先端の技術を組み合わせ、長期的な安定性、測定の不確実性の低減、過酷な測定環境への適応性、迅速な測定ポイントの特定、高度なユーザーエクスペリエンスを実現します。これらの計測ソリューションは、ライフサイクル全体にわたってメーカーに最大の価値を提供します。

堅牢な機械設計

アリ溝ガイドが統合された堅固な花崗岩ベースにより、長期間のシステム安定性と測定体積全体にわたる一貫した精度が保証されます。

三角クロスビーム付きブリッジ

正方形または長方形のトラバースに対して剛性質量比が改善されたこの設計は、最高の動特性および高速測定を可能にします。

全軸に設置された予荷重空気軸受

非接触、低摩擦、低摩耗の軸運動により、あらゆる速度と加速度で迅速で再現可能な位置決めを確保し、測定の不確実性を低減します。

低メンテナンスのベルトドライブシステム

平ベルトおよび Vリブドベルトにより、滑らかで振動の少ない軸動作が実現します。

温度補償

スケールおよびワークピースの温度を検出する際、熱によって起こされた測定偏差をリアルタイムに補償することで、信頼できる測定結果を保証します。

拡張動作温度範囲 (オプション)°

環境からの影響に高い抵抗性を発揮して部品を測定します。拡張動作温度の範囲が (15 - 30°C) であるため、CMM に高価な温度調節室が不要になり、製造ラインの近くで操作することできます。

リアルタイム環境モニタリング(オプション)

PULSEにより、CMM周辺の環境条件をモニターおよび記録し、リアルタイムで機械情報を受け取ることができます。

メッセージライト

メッセージライトは、オペレーターが離れた場所から機械の状態を監視することを可能にし、時間とリソース管理を最適化することができます。

高速度と安全性

CMM 周囲に設定された安全エリアを継続的にモニタリングすることで、 CNC モードによる安心な高速測定が可能になります。ユーザーや物体が安全エリアに侵入すると、機械は自動的に減速します。

マルチセンサーの汎用性

この CMM は Hexagon の汎用センサーインターフェースと最も広範な接触および光学センサーを使用し、最も複雑な測定作業に適応可能なマルチセンサー検査装置です。

将来に対応するコンセプト

事前配線は将来に対応し、高価なダウンタイムを回避しながら CMM を将来の測定業務に容易に適応させることできます。CMM の初期構成中にさまざまな適応性オプションを柔軟に選択するか、後日アップグレードとして設定することができます。

-

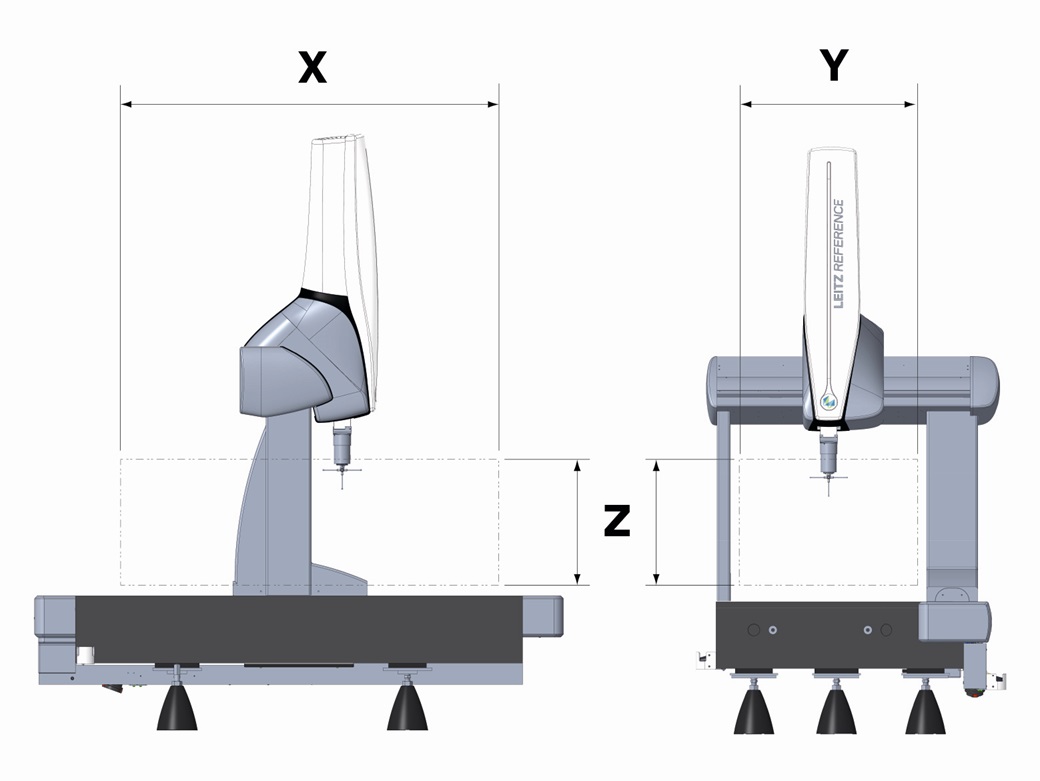

体積測定

シリアル番号 X (幅) Y (奥行き) Z (高さ) * 7.7.5 700 mm 700 mm 420 - 500 mm ** 10.7.6 1000 mm 700 mm 580 - 650 mm ** 12.9.7 1200 mm 900 mm 700 - 770 mm **

560 - 640 mm ***15.9.7 1500 mm 900 mm 700 - 770 mm **

560 - 640 mm ***20.9.7 2000 mm 900 mm 700 - 770 mm **

560 - 640 mm ***15.12.9 1500 mm 1200 mm 940 - 970 mm **

800 -880 mm ***22.12.9 2200 mm 1200 mm 940 - 970 mm **

800 - 880 mm ***30.12.9 3000 mm 1200 mm 940 - 970 mm **

800 - 880 mm ***40.12.9 4000 mm 1200 mm 940 - 970 mm **

800 - 880 mm **** 値は選択したセンサー構成により異なります

**SENMATION 非搭載の機械の値

***SENMATION 搭載の機械の値 -

Downloads