Reducing material waste generated by electronics batch production

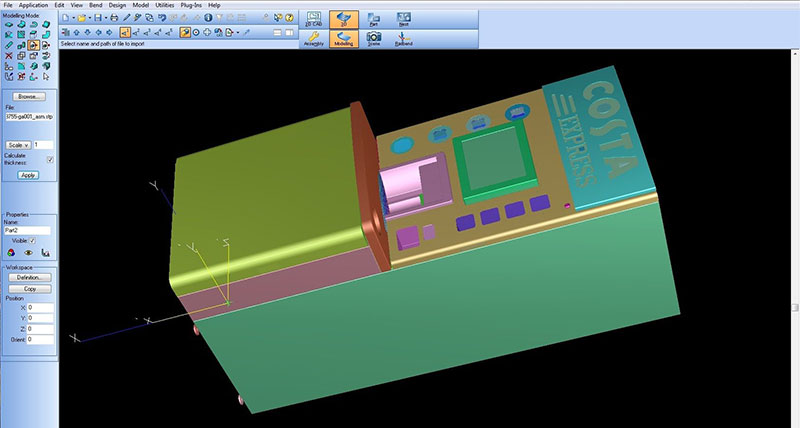

Hexagon’s sheetmetal CAD/CAM systems give electronic manufacturers the insight they need to make more efficient use of materials when manufacturing.

Contact us

Whether manufacturing large quantities of components, or small sample batches, sheet metal manufacturers serving the electronics sector can reduce costs and improve sustainability by reducing scrap.

Several techniques exist to reduce the waste of sheet metal during production of electronics equipment such as metal enclosures. Nesting, for example, enables electronic component manufacturers to lay out cutting patterns in ways that minimize material waste. Other methods include simulating the full bending sequence of a metal part before starting to fold it.

With Hexagon’s RADAN CAD/CAM software specialised for the sheet metal industry, electronic component manufacturers can manage 2D and 3D design, part nesting, punching, profiling, bending, production control and cost estimation of sheet metal components in a single environment.