Mine Production Drilling

Streamline the drill and blast workflow from design to reconciling, planning and fragmentation.

Introducing a Data-Driven Approach to the Drill And Blast Workflow

Keep production crews and other stakeholders directly informed of your planned and designed blast holes.

Hexagon can help you integrate and streamline the drill and blast workflow with tools for blast design, safety exclusion zones, charge information and reconciliation between planned and actual fragmentation.

Overview

Planning blast holes without feedback or a direct way to share design data with production crews can lead to costly misunderstandings.

Hexagon provides a holistic, data-driven approach to all facets of the drill and blast process, including mine production drilling. This approach comprises a rapid design utility that allows you to create and store templates, complete bootleg analysis and create safety exclusion zones for equipment and personnel based on actual terrain in a 3D environment.

Charge information per hole is assigned based on rock hardness, ore type classification or other factors to optimise fragmentation. Survey, timing and charge instructions can be viewed in the application and communicated to other stakeholders.

Once holes are drilled and loaded in the field, actual results can be imported back to the utility for tracking plan versus actual Key Performance Indicators (KPIs), such as horizontal, vertical, depth and charge compliance.

Explore

$ProductName

$SustainabilityImpactLabel

$SustainabilityCTABandHeadingLabel

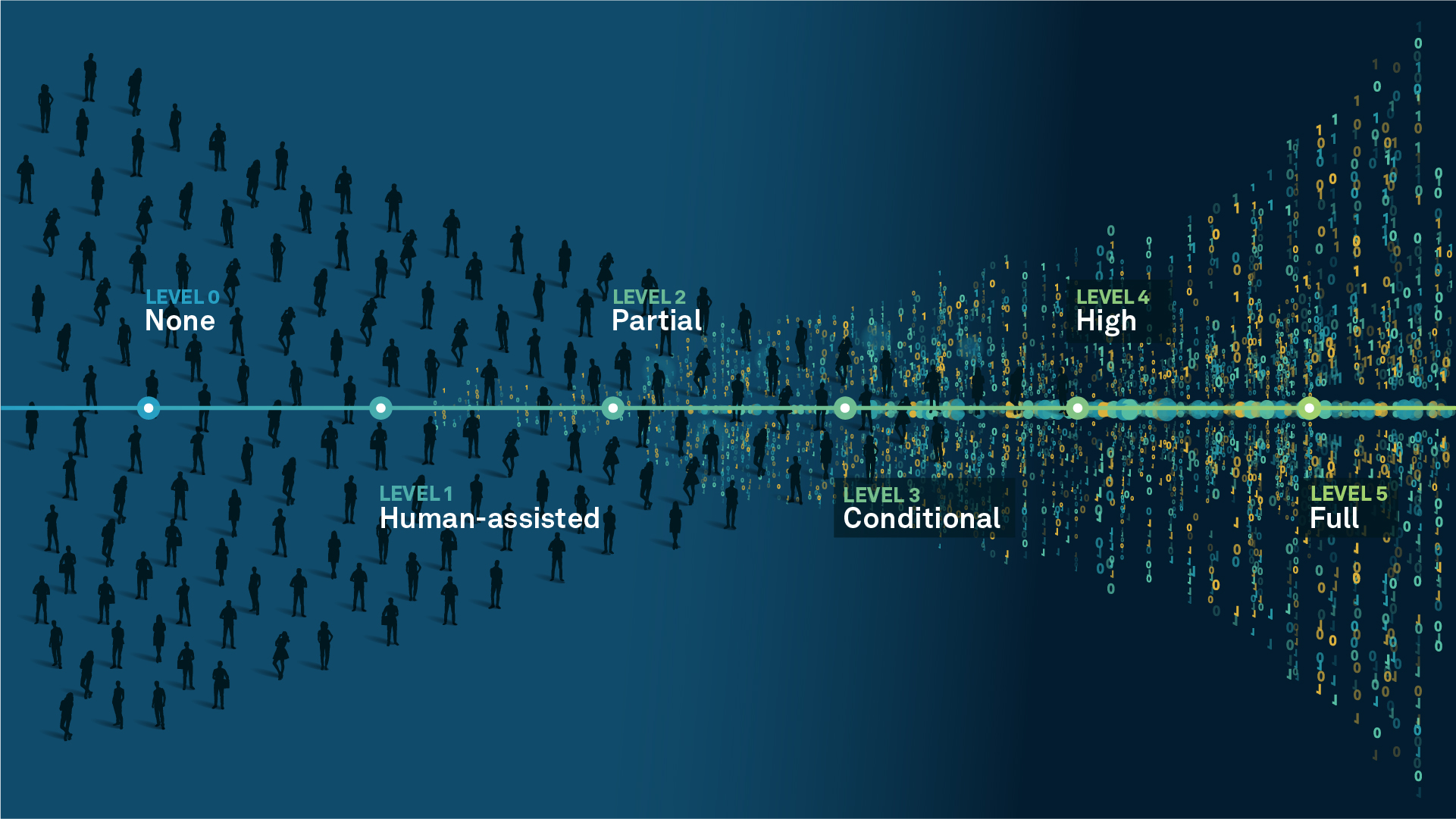

We’re climbing the automation curve

Our transition to Intelligent automation is accelerating. Ultimately, our innovations will give rise to new technologies and applications - many of which we’ve yet to imagine. Today, every Hexagon solution is mapped and tagged according to its level of automation, so customers can clearly track our progress towards the freedom of autonomy.

Human-driven

All tasks completed by human labour; no data is leveraged across the operation.

Human-assisted

Labour is primarily conducted by a human workforce. Some functions have been automated to simplify control.

Partial automation

Some tasks are automated for short periods of time, accompanied by occasional human intervention.

Conditional automation

Human workforce is used for intervention as autonomous operations begin to increase productivity.

Highly autonomous

Autonomous systems complete required tasks within specific bounds, unleashing data and building smart digital realities.

Full autonomy

A smart digital reality™ enables autonomous systems to complete all tasks without human intervention.

Land

Products that make an environmental impact in forest monitoring, material reusability, farming or water usage.

Air

Products that make an environmental impact in renewable energy, noise pollution elimination and e-mobility.

Water

Products that make an environmental impact in saving our oceans, reducing pollution and increasing access to clean water.