Partnership adds muscle to gym equipment production

Watson Gym Equipment - U.K.

Contact us

A partnership between Mazak and the powerful market-leading RADAN CAD/CAM software has slashed the time taken by a gym equipment manufacturer to build a piece of apparatus from two days to half a day.

Watson Gym Equipment works exclusively in the fitness industry, supplying strength equipment to high-end PT gyms, for training professional and Olympic athletes. Operating with 40 employees out of premises totalling 40,000 square feet, the company ships around 30 per cent of its products to Australia with another 30 per cent going to the USA. Twenty-five per cent stays in the UK (some of which is for top-end home gyms – for example, footballer John Terry is a customer), with the remainder destined for Europe and the Middle East.

Their product range of around 200 machines is geared towards those where weights and weight plates are added, focusing on anaerobic exercises to increase strength. They are manufactured from sheet metal, and box section steel.

Their product range of around 200 machines is geared towards those where weights and weight plates are added, focusing on anaerobic exercises to increase strength. They are manufactured from sheet metal, and box section steel.

Managing Director Simon Watson says a partnership between their CNC machine tool supplier Mazak, and CAD/CAM specialist RADAN, has completely transformed the way they now cut that box section steel.

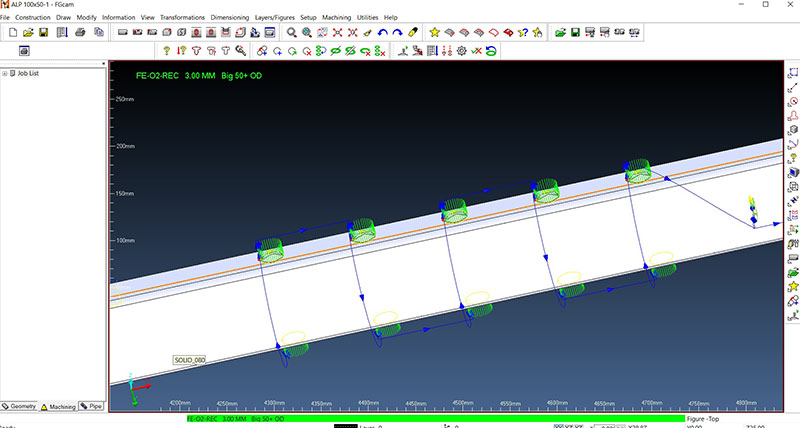

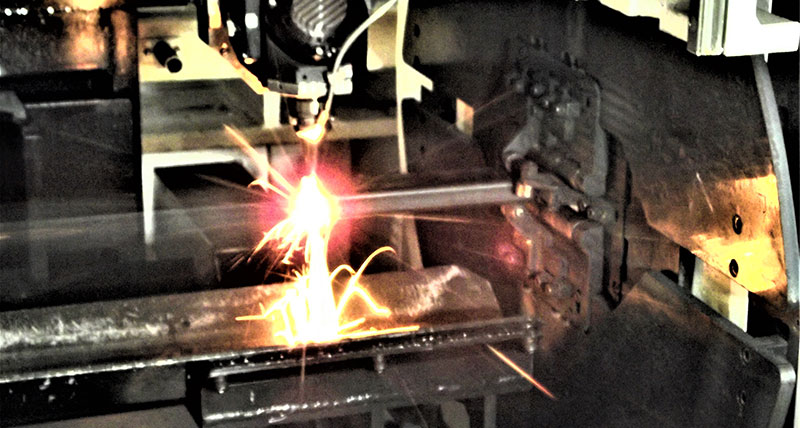

It is all carried out on a Mazak Fabri Gear 220 ll laser tube cutter, pre-installed with Mazak’s FG-CAD/CAM, a software powered by RADAN’s laser tube system, Radtube. This processes the most complex pipe and box section shapes in a fraction of the time taken by traditional methods.

“It replaces what we used to do manually, which was to take an eight-metre length of steel, cut it to the length we needed for the component on our piece of apparatus, mitre it and put the holes in.”

Another major advantage is that it enables tabs to be created in a style that the apparatus can only be put together one way. “We use different sized tabs and make them non-symmetrical, so when the welder comes to fit the pieces together it’s like a jigsaw puzzle, completely eliminating human error at the assembly stage,” says Simon Watson.

The software can also readily program a scalloping out procedure, giving added strength to the joints. “It does everything we were doing by hand…and a lot more besides, such as the tabbing. Previously we had to draw both the tabs and slots. But now I just click where I want the tab, input the gap around it, and it automatically inserts the slot immediately. The software really is phenomenal. It’s definitely transformed the way we manufacture, by automating around 80 per cent of the manual work the welders were doing on cutting and preparation.”

Another part of the process that the Radtube-powered FG-CAD/CAM speeds up is where Simon Watson is designing box section components which are identical, except for the addition of holes...mainly for the frames of their weight machines. “One side may have numerous holes in it, but none in the other. Instead of having to draw it twice, I draw it once with the holes, create a mirror image, and put everything into FG-CAD/CAM and simply take out the holes.”

The company has used a Mazak mill, flatbed laser and two lathes to cut other components for several years. But it was seeing how much time the welders spent manually cutting and processing the box sections that prompted him to take the next step and invest in a laser tube cutter. “As well as the actual cutting being so time consuming, there was a lot of downtime for changing blades and maintaining saws. Also, when someone’s cutting lengths of steel 20 times, they’re not going to get all 20 to the exact same length.

The company has used a Mazak mill, flatbed laser and two lathes to cut other components for several years. But it was seeing how much time the welders spent manually cutting and processing the box sections that prompted him to take the next step and invest in a laser tube cutter. “As well as the actual cutting being so time consuming, there was a lot of downtime for changing blades and maintaining saws. Also, when someone’s cutting lengths of steel 20 times, they’re not going to get all 20 to the exact same length.

“But with the laser tube cutter CNC machine and specialist software we noticed massive improvements in time and accuracy right from the start. And it’s so easy to use. I felt quite comfortable doing basic tasks after just one day’s training. Within a couple of weeks I was completely comfortable doing anything.”

Concluding, Simon Watson says: “The Fabri Gear and FG-CAD/CAM makes everything consistent and uniform, and also means if we need to replace any parts on an existing piece of apparatus we know the new part will be completely accurate.”

Watson Gym Equipment works exclusively in the fitness industry, supplying strength equipment to high-end PT gyms, for training professional and Olympic athletes. Operating with 40 employees out of premises totalling 40,000 square feet, the company ships around 30 per cent of its products to Australia with another 30 per cent going to the USA. Twenty-five per cent stays in the UK (some of which is for top-end home gyms – for example, footballer John Terry is a customer), with the remainder destined for Europe and the Middle East.

Their product range of around 200 machines is geared towards those where weights and weight plates are added, focusing on anaerobic exercises to increase strength. They are manufactured from sheet metal, and box section steel.

Their product range of around 200 machines is geared towards those where weights and weight plates are added, focusing on anaerobic exercises to increase strength. They are manufactured from sheet metal, and box section steel.Managing Director Simon Watson says a partnership between their CNC machine tool supplier Mazak, and CAD/CAM specialist RADAN, has completely transformed the way they now cut that box section steel.

It is all carried out on a Mazak Fabri Gear 220 ll laser tube cutter, pre-installed with Mazak’s FG-CAD/CAM, a software powered by RADAN’s laser tube system, Radtube. This processes the most complex pipe and box section shapes in a fraction of the time taken by traditional methods.

“It replaces what we used to do manually, which was to take an eight-metre length of steel, cut it to the length we needed for the component on our piece of apparatus, mitre it and put the holes in.”

Another major advantage is that it enables tabs to be created in a style that the apparatus can only be put together one way. “We use different sized tabs and make them non-symmetrical, so when the welder comes to fit the pieces together it’s like a jigsaw puzzle, completely eliminating human error at the assembly stage,” says Simon Watson.

The software can also readily program a scalloping out procedure, giving added strength to the joints. “It does everything we were doing by hand…and a lot more besides, such as the tabbing. Previously we had to draw both the tabs and slots. But now I just click where I want the tab, input the gap around it, and it automatically inserts the slot immediately. The software really is phenomenal. It’s definitely transformed the way we manufacture, by automating around 80 per cent of the manual work the welders were doing on cutting and preparation.”

Another part of the process that the Radtube-powered FG-CAD/CAM speeds up is where Simon Watson is designing box section components which are identical, except for the addition of holes...mainly for the frames of their weight machines. “One side may have numerous holes in it, but none in the other. Instead of having to draw it twice, I draw it once with the holes, create a mirror image, and put everything into FG-CAD/CAM and simply take out the holes.”

The company has used a Mazak mill, flatbed laser and two lathes to cut other components for several years. But it was seeing how much time the welders spent manually cutting and processing the box sections that prompted him to take the next step and invest in a laser tube cutter. “As well as the actual cutting being so time consuming, there was a lot of downtime for changing blades and maintaining saws. Also, when someone’s cutting lengths of steel 20 times, they’re not going to get all 20 to the exact same length.

The company has used a Mazak mill, flatbed laser and two lathes to cut other components for several years. But it was seeing how much time the welders spent manually cutting and processing the box sections that prompted him to take the next step and invest in a laser tube cutter. “As well as the actual cutting being so time consuming, there was a lot of downtime for changing blades and maintaining saws. Also, when someone’s cutting lengths of steel 20 times, they’re not going to get all 20 to the exact same length.“But with the laser tube cutter CNC machine and specialist software we noticed massive improvements in time and accuracy right from the start. And it’s so easy to use. I felt quite comfortable doing basic tasks after just one day’s training. Within a couple of weeks I was completely comfortable doing anything.”

Concluding, Simon Watson says: “The Fabri Gear and FG-CAD/CAM makes everything consistent and uniform, and also means if we need to replace any parts on an existing piece of apparatus we know the new part will be completely accurate.”