AE Aerospace and Edgecam reach new heights

Without Edgecam we wouldn’t be able to look at the new 5-axis work that’s coming through from our customers.

Contact us

AE Aerospace has celebrated the 2nd anniversary following its highly successful MBO by Peter Bruch and Andy Masters in 2014. The Birmingham-based company has established itself as a significant player in the precision components market. It supplies components and assemblies to many of the civil and military aircraft currently in service around the world.

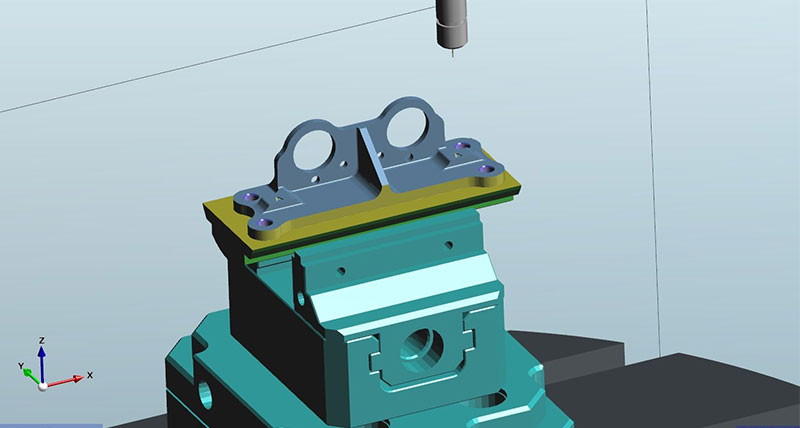

Projects include airframe, power plant, and both fixed and rotary wing. Individual components range from small washers up to complex 5-axis prismatic valve body components. Managing Director Peter Bruch says:

AE Aerospace holds the aerospace industry SC21 bronze award and is aiming to achieve silver in 2016. Production and Engineering Director Andy Masters, says: “The engineering department is constantly working on reducing the cost of each component through improved machining times and techniques, and reduced set-up times. We carefully choose the partners that we work with to ensure that all systems are compatible and help speed production. We’ve recently doubled our Edgecam seats because of its ability to program complex components offline and seamless integration with our latest Mazak 5-Axis VariAxis milling and 5-Axis Integrex mill-turn machine tools.

AE Aerospace holds the aerospace industry SC21 bronze award and is aiming to achieve silver in 2016. Production and Engineering Director Andy Masters, says: “The engineering department is constantly working on reducing the cost of each component through improved machining times and techniques, and reduced set-up times. We carefully choose the partners that we work with to ensure that all systems are compatible and help speed production. We’ve recently doubled our Edgecam seats because of its ability to program complex components offline and seamless integration with our latest Mazak 5-Axis VariAxis milling and 5-Axis Integrex mill-turn machine tools.

“As we sought to develop the business and move up the supply chain by offering complex milling and mill-turn, one of our main differentiators was our ability to get work into production extremely quickly, along with the quality, delivery and cost that the customer is looking for. The combination of Edgecam with Mazak machine tools has been instrumental in our ability to succeed.” Engineering Manager Lester Poxon says: “Without Edgecam we wouldn’t be able to look at the new 5-axis work that’s coming through from our customers. Two years ago we were focused on strangers and aliens and NPI work. We have successfully transitioned this work into OE production and now those same customers are looking for us to take on more complex components and larger packages of work. Edgecam gives us the ability to program complex parts offline.

“With the new investment we have received, it’s a very exciting time for the Engineering Department.

“Edgecam is a very valuable tool, enabling us to be more competitive. It helps us produce accurate costs based on real tool paths and cycle times, meaning we can have programs ready before we even win the contract.”

In addition, they work with cutting tool manufacturer, Seco – who are an Edgecam business partner. “As Seco use Edgecam, their engineers can help us produce the very best cutting strategies, which is a tremendous benefit for our customers.” manufactures over 200 different OE components and a similar number of spares, strangers and alien parts. Over 25,000 parts go through the facility annually.

The company manages its business and drives improvement through a set of metrics for People, Quality, Delivery and Cost. They work to Rolls Royce CDS Supplier Development programme and UTC Supplier Gold. AE Aerospace holds the aerospace industry SC21 bronze award and is aiming to achieve silver in 2016. Production and Engineering Director Andy Masters, says: “The engineering department is constantly working on reducing the cost of each component through improved machining times and techniques, and reduced set-up times. We carefully choose the partners that we work with to ensure that all systems are compatible and help speed production. We’ve recently doubled our Edgecam seats because of its ability to program complex components offline and seamless integration with our latest Mazak 5-Axis VariAxis milling and 5-Axis Integrex mill-turn machine tools. “As we sought to develop the business and move up the supply chain by offering complex milling and mill-turn, one of our main differentiators was our ability to get work into production extremely quickly, along with the quality, delivery and cost that the customer is looking for. The combination of Edgecam with Mazak machine tools has been instrumental in our ability to succeed.”

“As we sought to develop the business and move up the supply chain by offering complex milling and mill-turn, one of our main differentiators was our ability to get work into production extremely quickly, along with the quality, delivery and cost that the customer is looking for. The combination of Edgecam with Mazak machine tools has been instrumental in our ability to succeed.”

Engineering Manager Lester Poxon says: “Without Edgecam we wouldn’t be able to look at the new 5-axis work that’s coming through from our customers. Two years ago we were focused on strangers and aliens and NPI work. We have successfully transitioned this work into OE production and now those same customers are looking for us to take on more complex components and larger packages of work. Edgecam gives us the ability to program complex parts offline.

“With the new investment we have received, it’s a very exciting time for the Engineering Department.

“Edgecam is a very valuable tool, enabling us to be more competitive. It helps us produce accurate costs based on real tool paths and cycle times, meaning we can have programs ready before we even win the contract.”

In addition, they work with cutting tool manufacturer, Seco – who are an Edgecam business partner. “As Seco use Edgecam, their engineers can help us produce the very best cutting strategies, which is a tremendous benefit for our customers.” AE Aerospace’s customer list features a number of first & second tier, including Rolls Royce Derby and CDS, UTC Actuation Systems, Moog, Bombardier, Eaton, BAE Systems and Liebherr.

The success that AE Aerospace has achieved has enabled them to purchase Andover Precision, based in Netherton in the Black Country. Andover Precision specialises in components for marine and power generation applications as well as aerospace. Customers include Rolls Royce Marine, Doncasters and Pattonair. Both companies hold numerous customer approvals, AS9100 approvals and, together, form the TI Dos Aerospace group. Peter Bruch says: “We’re applying the same methodology to Andover Precision as we did to AE Aerospace, which has made it so successful over such a short space of time, investing in our people, equipment and software. This includes installing their first Edgecam seats, new Mazak machine tools and combining our DNAsme ERP system.”

“We have a skilled and dedicated team which has made the difference, enabling us to triple our turnover and order book in the past 2 years, allowing us to make significant investment in our people, equipment and software.”Having almost doubled employment of skilled engineers and introduced an apprenticeship programme, AE Aerospace manufactures over 200 different OE components and a similar number of spares, strangers and alien parts. Over 25,000 parts go through the facility annually.

The company manages its business and drives improvement through a set of metrics for People, Quality, Delivery and Cost.

They work to Rolls Royce CDS Supplier Development programme and UTC Supplier Gold.

AE Aerospace holds the aerospace industry SC21 bronze award and is aiming to achieve silver in 2016. Production and Engineering Director Andy Masters, says: “The engineering department is constantly working on reducing the cost of each component through improved machining times and techniques, and reduced set-up times. We carefully choose the partners that we work with to ensure that all systems are compatible and help speed production. We’ve recently doubled our Edgecam seats because of its ability to program complex components offline and seamless integration with our latest Mazak 5-Axis VariAxis milling and 5-Axis Integrex mill-turn machine tools.

AE Aerospace holds the aerospace industry SC21 bronze award and is aiming to achieve silver in 2016. Production and Engineering Director Andy Masters, says: “The engineering department is constantly working on reducing the cost of each component through improved machining times and techniques, and reduced set-up times. We carefully choose the partners that we work with to ensure that all systems are compatible and help speed production. We’ve recently doubled our Edgecam seats because of its ability to program complex components offline and seamless integration with our latest Mazak 5-Axis VariAxis milling and 5-Axis Integrex mill-turn machine tools. “As we sought to develop the business and move up the supply chain by offering complex milling and mill-turn, one of our main differentiators was our ability to get work into production extremely quickly, along with the quality, delivery and cost that the customer is looking for. The combination of Edgecam with Mazak machine tools has been instrumental in our ability to succeed.” Engineering Manager Lester Poxon says: “Without Edgecam we wouldn’t be able to look at the new 5-axis work that’s coming through from our customers. Two years ago we were focused on strangers and aliens and NPI work. We have successfully transitioned this work into OE production and now those same customers are looking for us to take on more complex components and larger packages of work. Edgecam gives us the ability to program complex parts offline.

“With the new investment we have received, it’s a very exciting time for the Engineering Department.

“Edgecam is a very valuable tool, enabling us to be more competitive. It helps us produce accurate costs based on real tool paths and cycle times, meaning we can have programs ready before we even win the contract.”

In addition, they work with cutting tool manufacturer, Seco – who are an Edgecam business partner. “As Seco use Edgecam, their engineers can help us produce the very best cutting strategies, which is a tremendous benefit for our customers.” manufactures over 200 different OE components and a similar number of spares, strangers and alien parts. Over 25,000 parts go through the facility annually.

The company manages its business and drives improvement through a set of metrics for People, Quality, Delivery and Cost. They work to Rolls Royce CDS Supplier Development programme and UTC Supplier Gold. AE Aerospace holds the aerospace industry SC21 bronze award and is aiming to achieve silver in 2016. Production and Engineering Director Andy Masters, says: “The engineering department is constantly working on reducing the cost of each component through improved machining times and techniques, and reduced set-up times. We carefully choose the partners that we work with to ensure that all systems are compatible and help speed production. We’ve recently doubled our Edgecam seats because of its ability to program complex components offline and seamless integration with our latest Mazak 5-Axis VariAxis milling and 5-Axis Integrex mill-turn machine tools.

“As we sought to develop the business and move up the supply chain by offering complex milling and mill-turn, one of our main differentiators was our ability to get work into production extremely quickly, along with the quality, delivery and cost that the customer is looking for. The combination of Edgecam with Mazak machine tools has been instrumental in our ability to succeed.”

“As we sought to develop the business and move up the supply chain by offering complex milling and mill-turn, one of our main differentiators was our ability to get work into production extremely quickly, along with the quality, delivery and cost that the customer is looking for. The combination of Edgecam with Mazak machine tools has been instrumental in our ability to succeed.”Engineering Manager Lester Poxon says: “Without Edgecam we wouldn’t be able to look at the new 5-axis work that’s coming through from our customers. Two years ago we were focused on strangers and aliens and NPI work. We have successfully transitioned this work into OE production and now those same customers are looking for us to take on more complex components and larger packages of work. Edgecam gives us the ability to program complex parts offline.

“With the new investment we have received, it’s a very exciting time for the Engineering Department.

“Edgecam is a very valuable tool, enabling us to be more competitive. It helps us produce accurate costs based on real tool paths and cycle times, meaning we can have programs ready before we even win the contract.”

In addition, they work with cutting tool manufacturer, Seco – who are an Edgecam business partner. “As Seco use Edgecam, their engineers can help us produce the very best cutting strategies, which is a tremendous benefit for our customers.” AE Aerospace’s customer list features a number of first & second tier, including Rolls Royce Derby and CDS, UTC Actuation Systems, Moog, Bombardier, Eaton, BAE Systems and Liebherr.

The success that AE Aerospace has achieved has enabled them to purchase Andover Precision, based in Netherton in the Black Country. Andover Precision specialises in components for marine and power generation applications as well as aerospace. Customers include Rolls Royce Marine, Doncasters and Pattonair. Both companies hold numerous customer approvals, AS9100 approvals and, together, form the TI Dos Aerospace group. Peter Bruch says: “We’re applying the same methodology to Andover Precision as we did to AE Aerospace, which has made it so successful over such a short space of time, investing in our people, equipment and software. This includes installing their first Edgecam seats, new Mazak machine tools and combining our DNAsme ERP system.”