PRESTO

Enabling the future of automated inspection

End-to-end automated inspection in a turnkey package

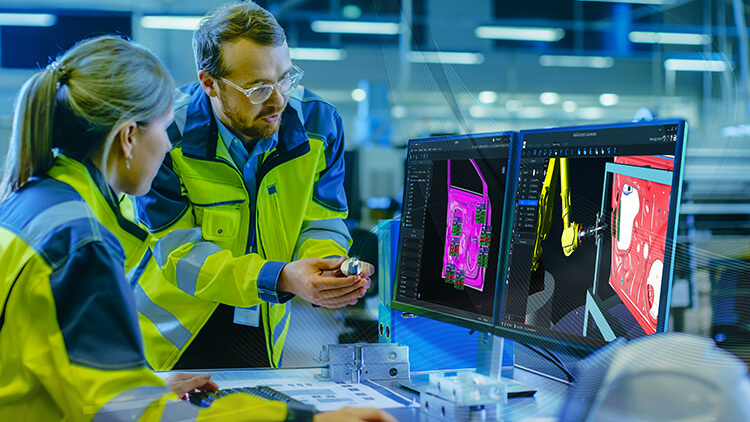

As a combination of proven solutions from the Hexagon’s manufacturing technology portfolio, PRESTO is an automated inspection cell that enables start-to-end throughput – a seamless and efficient 3D scanning workflow for part inspection.

Designed to be seamlessly integrated into your shop-floor workflows

The PRESTO concept is all about simplicity – making it easier for anyone to run the process that delivers the data that makes manufacturing better.

- Programmed with intuitive built-in workflows, PRESTO is accessible for users who are non experts in robotics and metrology.

- As PRESTO is software-agnostic, your teams do not have to learn and use a new software.

- However, our large installed base of PC-DMIS users get superior benefits with seamless connectivity throughout the entire inspection process.

All operators – no matter their training – are only a few clicks away from the metrology report.

Get the best of your inspection asset

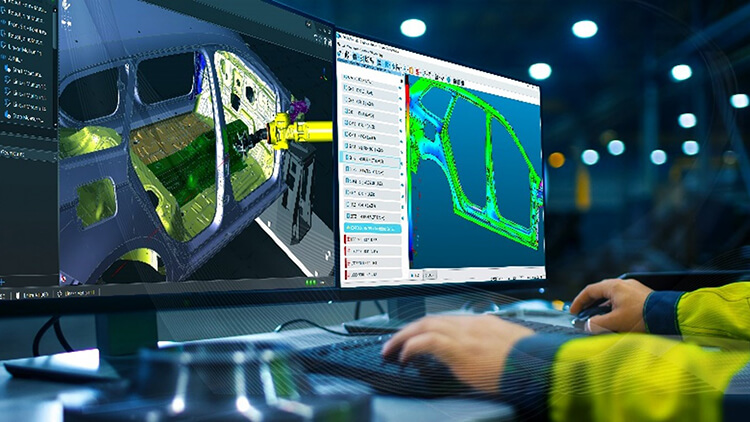

Cell modelling is no longer needed

- PRESTO cell is pre-engineered as a factory setting.

- Simply import your CAD or PMI files from your preferred metrology software with one direct button.

Reduce inspection downtime

- Enable offline programming mode to free the cell for actual inspection program

No need for a robot engineer

- Choose Automatic Anti-Collision Path programming and let the software work for you

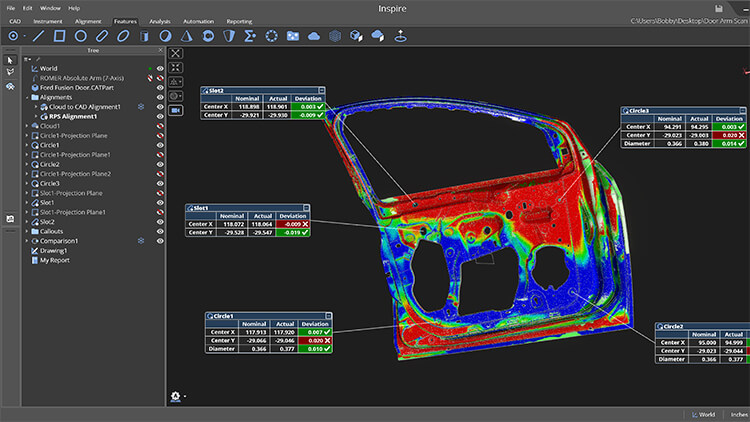

Cut inspection time, by half*

Paired with Leica Absolute Tracker AT960, the Absolute Scanner AS1 is a blue laser line scanner that captures 1.2 million points per second, and is therefore fundamental in allowing PRESTO to collect high definition inspection data at very high speed

- Minimal setup time : start scanning directly, since no part preparation is required

- Scan any surface, even highly reflective material finishes, without using any spray

- High, proven accuracy thanks to Absolute Measurements

* Pending internal lab tests, performed on a door, achieving 100% part coverage :

- Horizontal arm + Optical scanner : 12 min

- PRESTO : 6 min

![]()

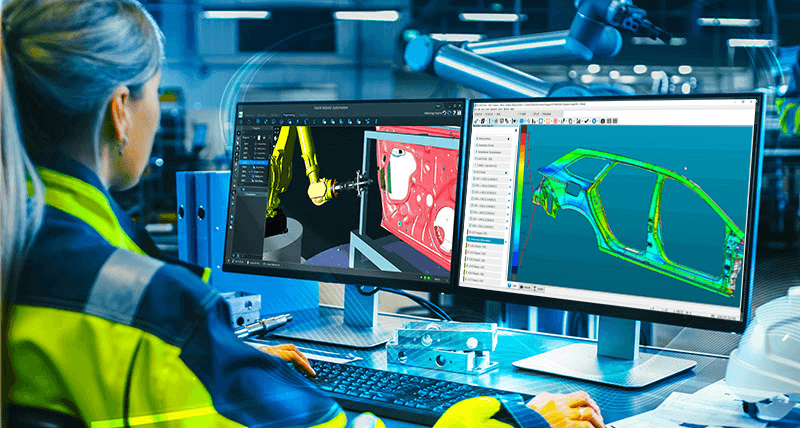

Contribute to insights

Data collected during the inspection process collates a wealth of data that can be leveraged by both the inspection department and the wider organisation.

Over time, the growing compilation of inspection data will create an abundance of customer insights and knowledge – this is data with the potential to unlock new pathways and processes, creating a pipeline for future actions across the business

- True digital twins: high quality data to generate your product digital twin and optimise the product lifecycle management

- Process Data Traceability : collected data incorporates all metadata, recording the complete story of any inspected part

- Data interoperability: increase the effi ciency and accuracy of data-driven decisions with data that remains accessible and usable over time.

- Learn more

-

Success storyTwo new robotic measuring cells from Hexagon represent a new generation of innovative automated optical 3D measurement across the entire Volkswagen Group.