HxGN Visual Detection

Automate quality inspection and detect defects faster

Want to learn more?

What is HxGN Visual Detection?

Explore the HxGN Visual Detection automated surface inspection application.

What is HxGN Visual Detection?

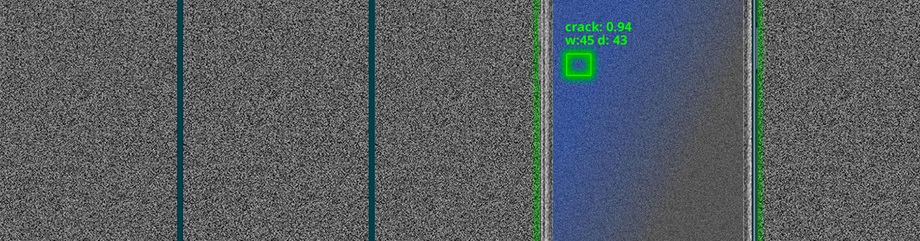

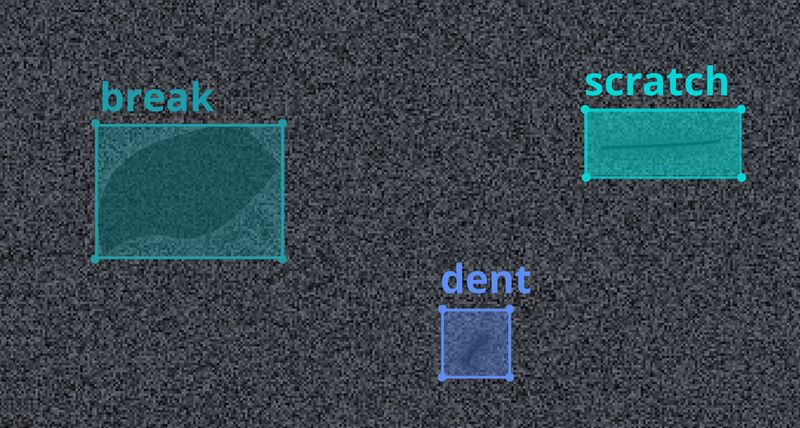

HxGN Visual Detection is an automated surface inspection application capable of detecting defects such as scratches, cracks and dirt, on materials like glass, metal, plastics, ceramics and textiles.

Learn more

Why choose HxGN Visual Detection?

The easy-to-use HxGN Visual Detection application significantly reduces the time and costs associated with automating checks on surface materials.

Flexible and fast

HxGN Visual Detection uses AI to learn from a small set of training images, so it can be quickly reconfigured to support a change of product.

Improve quality

Locate and recognise defects with an excellent level of accuracy. Reduce rework, limit quality-related downtime and minimise project costs.

Simple to use

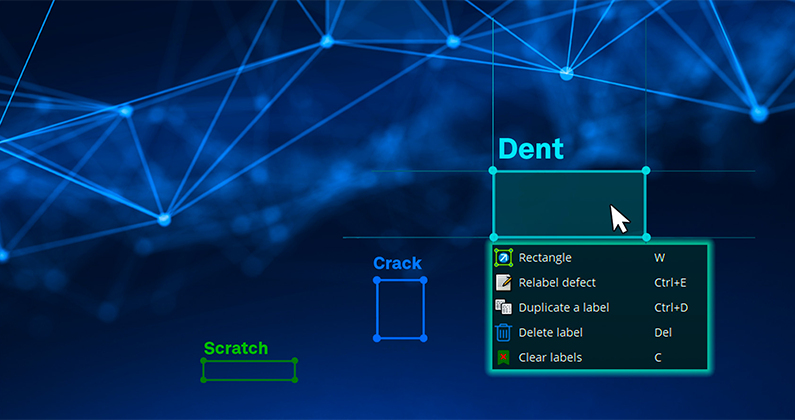

Quickly train HxGN Visual Detection to identify errors by drawing rectangles around scratches or dents in your sample image set.

Extend your quality solution

HxGN Visual Detection can be used as a standalone application or integrated into larger manufacturing cells. See how it integrates with PC-DMIS Vision and Optiv vision systems as part of the wider quality ecosystem.

Learn more

How HxGN Visual Detection works

Explore how HxGN Visual Detection leverages advanced machine learning to recognise surface defects based on training imagery.