The new life of an old radiator mascot

Rapid Prototyping with the AICON SmartScan

Contact us

Ford, Rolls Royce, Daimler and Benz – only a small selection of the illustrious names of the early beginnings of automotive manufacturing. Nowadays, car enthusiasts all over the world lovingly maintain and restore the few remaining classic cars, some of which are over 100 years old. Preserving the roadworthiness of these valuable antique cars however comes with a catch: Over the past years, it has become increasingly difficult to meet the demand for original fully functional spare parts.

In the context of engine and vehicle components, the scan data can be converted into a surface model with the help of the reverse engineering software Rapidform XOR3 which is then used, for instance, for the creation of aluminum cast molds.

This very problem also applies to the American luxury automobiles of the Packard Motor Car Company manufactured in the first half of the 20th century. Apart from the spare parts for engine components, in particular the meticulously detailed decorative items of the various classic car models are much sought after among the Packard automobile owners.

This very problem also applies to the American luxury automobiles of the Packard Motor Car Company manufactured in the first half of the 20th century. Apart from the spare parts for engine components, in particular the meticulously detailed decorative items of the various classic car models are much sought after among the Packard automobile owners.

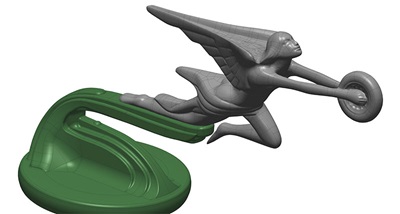

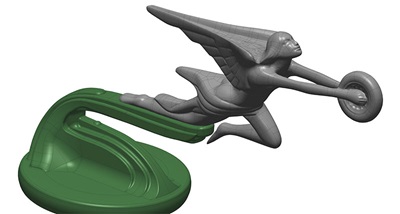

The „Goddess of Speed“ which graces a number of Packard models of the nineteen thirties and forties as a bonnet mascot is one of these much sought after objects of desire. A technologically easily feasible alternative to the often tedious and costly acquisition of the original component is the creation of true to detail replica. To do so, there are basically two major production methods: On the one hand, there is the rapid prototyping approach in combination with a 3D printer, on the other hand, there is the reverse engineering approach for the fabrication of cast molds of the original object. The generation of the three-dimensional data sets of the original specimen required for each of these methods is accomplished with the help of an AICON SmartScan.

The data acquisition of the mascot is carried out with the aid of a turntable, allowing for a predominantly automated digitization of the measuring object. Occasional areas which were missed out during the digitization process are easily filled in with additional data captures.

Signs of scratches or holes on the original figurine which have also been captured in the scanning process, are easily rectified simply by removing these flaws in the respective digitized data sets or within the reverse engineering process: Every single time, therefore, the result is an impeccable and unspoilt surface. The digital image of the mascot is provided in various standard data formats, one of which being the STL format required for the subsequent 3D print generation.

Signs of scratches or holes on the original figurine which have also been captured in the scanning process, are easily rectified simply by removing these flaws in the respective digitized data sets or within the reverse engineering process: Every single time, therefore, the result is an impeccable and unspoilt surface. The digital image of the mascot is provided in various standard data formats, one of which being the STL format required for the subsequent 3D print generation.

For the production of cast molds, a 3D data set (polygon mesh) is calculated upon completion of the data acquisition of the entire object and then exported to the reverse engineering software Rapidform XOR3. The three-dimensional model of the object is acquired from the scanning process in order to perform the reverse engineering process and to generate a complete CAD data set. To verify the reverse engineering, the 3D model (polygon mesh) and the reversed data set (CAD model) are compared against each other within a matter of seconds; any identified deviations from the original are visualized using the method of false color mapping.

Thanks to the highly accurate digitization results using the AICON SmartScan, also an engine component can, for example, be three-dimensionally reproduced at very high level of precision, and with the aid of the specialized software Rapidform be prepared for the subsequent production.

In cases in which original parts are no longer available in sufficient quantities, modern technologies thus offer new and efficient alternatives, for example the production of replica using the methods of rapid prototyping or mold casting.

In cases in which original parts are no longer available in sufficient quantities, modern technologies thus offer new and efficient alternatives, for example the production of replica using the methods of rapid prototyping or mold casting.

For each process, the AICON SmartScan easily, swiftly and reliably generates the required 3D data. Thanks to this ingenious approach, the „Goddess of Speed“ will also in the future be able to grace the occasional stately Packard classic car model which has already lost its original bonnet mascot in its long ‘automobile life’.

We would like to express our appreciation to Mr. Peter Herzog for kindly loaning us one of the rare originals of the „Goddess of Speed“.

Newly produced desired unique pieces

The contact free scanning process is also ideally suited for very sensitive or fragile objects, whereby the digitization project consists of two main phases: In a first step, the SmartScan is used to produce a three-dimensional data capture of the radiator mascot. The resulting product, a virtual image (STL data set) of the original figurine, serves as basis for the creation of the replica with the aid of a 3D printer (rapid prototyping method).In the context of engine and vehicle components, the scan data can be converted into a surface model with the help of the reverse engineering software Rapidform XOR3 which is then used, for instance, for the creation of aluminum cast molds.

This very problem also applies to the American luxury automobiles of the Packard Motor Car Company manufactured in the first half of the 20th century. Apart from the spare parts for engine components, in particular the meticulously detailed decorative items of the various classic car models are much sought after among the Packard automobile owners.

This very problem also applies to the American luxury automobiles of the Packard Motor Car Company manufactured in the first half of the 20th century. Apart from the spare parts for engine components, in particular the meticulously detailed decorative items of the various classic car models are much sought after among the Packard automobile owners.The „Goddess of Speed“ which graces a number of Packard models of the nineteen thirties and forties as a bonnet mascot is one of these much sought after objects of desire. A technologically easily feasible alternative to the often tedious and costly acquisition of the original component is the creation of true to detail replica. To do so, there are basically two major production methods: On the one hand, there is the rapid prototyping approach in combination with a 3D printer, on the other hand, there is the reverse engineering approach for the fabrication of cast molds of the original object. The generation of the three-dimensional data sets of the original specimen required for each of these methods is accomplished with the help of an AICON SmartScan.

Contact-free automated measurement

The contact-free scanning process is also ideally suited for very sensitive or fragile objects, whereby the digitization project consists of two main phases: In a first step, the AICON SmartScan is used to produce a three-dimensional data capture of the radiator mascot. The resulting product, a virtual image (STL data set) of the original figurine, serves as basis for the creation of the replica with the aid of a 3D printer (rapid prototyping method). In the context of engine and vehicle components, the scan data can be converted into a surface model with the help of the reverse engineering software Rapidform XOR3 which is then used, for instance, for the creation of aluminum cast molds.The data acquisition of the mascot is carried out with the aid of a turntable, allowing for a predominantly automated digitization of the measuring object. Occasional areas which were missed out during the digitization process are easily filled in with additional data captures.

Signs of scratches or holes on the original figurine which have also been captured in the scanning process, are easily rectified simply by removing these flaws in the respective digitized data sets or within the reverse engineering process: Every single time, therefore, the result is an impeccable and unspoilt surface. The digital image of the mascot is provided in various standard data formats, one of which being the STL format required for the subsequent 3D print generation.

Signs of scratches or holes on the original figurine which have also been captured in the scanning process, are easily rectified simply by removing these flaws in the respective digitized data sets or within the reverse engineering process: Every single time, therefore, the result is an impeccable and unspoilt surface. The digital image of the mascot is provided in various standard data formats, one of which being the STL format required for the subsequent 3D print generation.For the production of cast molds, a 3D data set (polygon mesh) is calculated upon completion of the data acquisition of the entire object and then exported to the reverse engineering software Rapidform XOR3. The three-dimensional model of the object is acquired from the scanning process in order to perform the reverse engineering process and to generate a complete CAD data set. To verify the reverse engineering, the 3D model (polygon mesh) and the reversed data set (CAD model) are compared against each other within a matter of seconds; any identified deviations from the original are visualized using the method of false color mapping.

Thanks to the highly accurate digitization results using the AICON SmartScan, also an engine component can, for example, be three-dimensionally reproduced at very high level of precision, and with the aid of the specialized software Rapidform be prepared for the subsequent production.

Fast 3D date for faithful replicas

Even involving large scale data volumes, thanks to using an automated digitization approach an efficient and reliable workflow is guaranteed for each scanning project. The AICON SmartScan digitization system generates a straightforward and fast evaluation of the measuring results, providing the user with a comprehensive data base for further processing. This not only guarantees an efficient material usage in the production process, but also ensures that down to the smallest detail, every copied mascot in its final result is an exact replica of its original. In cases in which original parts are no longer available in sufficient quantities, modern technologies thus offer new and efficient alternatives, for example the production of replica using the methods of rapid prototyping or mold casting.

In cases in which original parts are no longer available in sufficient quantities, modern technologies thus offer new and efficient alternatives, for example the production of replica using the methods of rapid prototyping or mold casting.For each process, the AICON SmartScan easily, swiftly and reliably generates the required 3D data. Thanks to this ingenious approach, the „Goddess of Speed“ will also in the future be able to grace the occasional stately Packard classic car model which has already lost its original bonnet mascot in its long ‘automobile life’.

We would like to express our appreciation to Mr. Peter Herzog for kindly loaning us one of the rare originals of the „Goddess of Speed“.