Making productivity gains with CMM asset management

Hexagon’s HxGN SFx | Asset management software gives Paragon Medical the data it needs to maximise CMM utilisation and optimise team performance.

Contact us

Paragon Medical: Improving uptime, utilisation and resource allocation

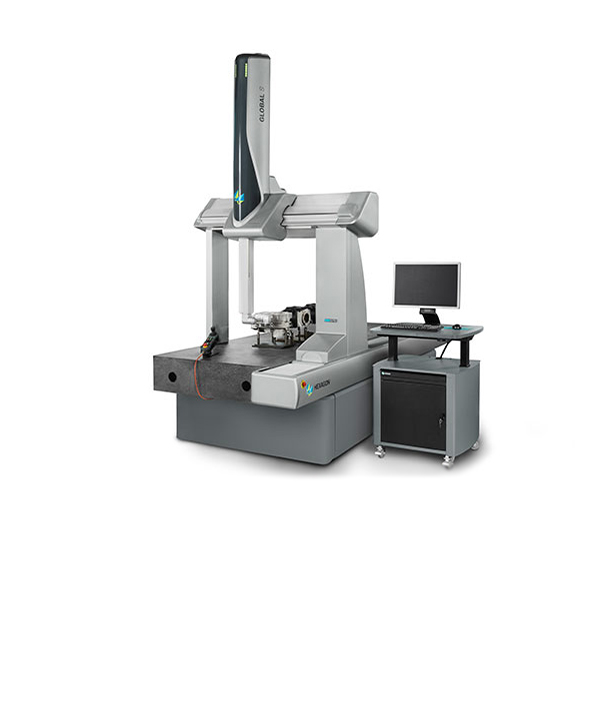

Investment in quality excellence has been a powerful motor behind the success of Paragon Medical. So, when Hexagon’s Manufacturing Intelligence division developed HxGN SFx | Asset Management software to monitor and analyse how key assets are performing via a centralised, user-friendly dashboard, Paragon Medical was keen to deploy it for its coordinate measuring machines (CMMs).

Founded in 1991 in the US, Paragon Medical employs 1300 people in the US, Europe and Asia and is a leading global supplier of cases and trays, surgical instruments, implantable components, and design and development services for the medical device marketplace. The company prides itself on developing and implementing world-class methods of engineering, manufacturing and product verification.

The company uses SFx Asset Management to monitor 14 Hexagon CMMs at its plant in Pierceton, Indiana, with plans to extend deployment to additional machines at another plant.

Real-time notifications

One of the immediate advantages of SFx Asset Management is the delivery of real-time notifications on the performance and status of CMMs, even while the machines are running unattended.“It is in daily use for us,” explains Ashlee Chapman, CMM Programmer, Paragon Medical. “With SFx Asset Management we know what we’re running, how efficiently it’s running; if there are any crashes on the floor, and if we have to help CMM operators with more training.”

And because managers receive notifications remotely, they can save time by being able to identify and rectify issues without having to visit the shop floor.

“We don’t have to step out on to the floor. We get real-time updates that … let us know which cells are having issues, or whether it is something to do with our programme,” says Ashlee.

It is particularly useful to receive real-time updates remotely during the night when there are no CMM programmers available on the shop floor.

“With the notifications we know if we have to make that call in the middle of the night because a machine is down, and we know what we’re stepping into the next day,” says Ashlee.

Improving operations and optimising machine usage

“Supervisors use the information to determine work-load, staffing and how much utilisation they are getting from the equipment in their cell,” says Jeff.

With SFx Asset Management, for example, supervisors are able to spot if operators are using certain measuring cells more than others.

“It is a huge benefit to be able to determine who is coming over to a particular measuring cell and why they are not going to another,” says Jeff.

For example, the team can evaluate whether certain CMMs are more popular because they perform more effectively, or whether it is other factors, such as the floor lay-out, that is driving heavier use of certain machines. With its mix of real-time and historical information SFx Asset Management provides game-changing insights into CMM operation.

“Imagine you have flight recorder information for your CMM.We have that,” says Jeff.