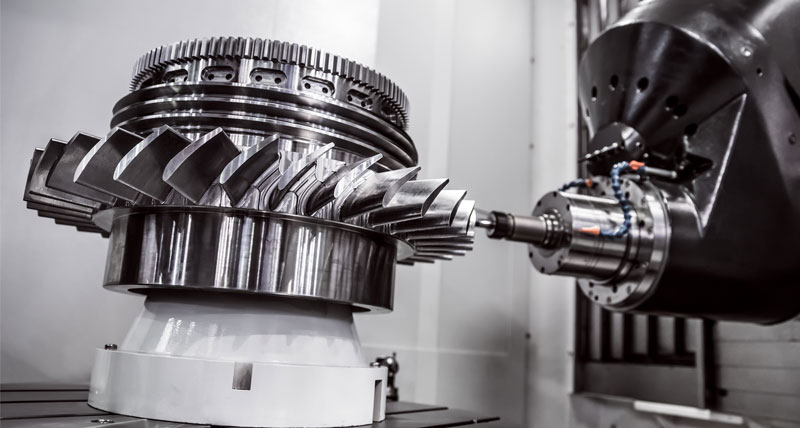

Machine tool probing for aligning aero engine turbine wheels

On-machine probing solutions for the alignment of aero engine turbine wheels during production

Contact us

The turbine wheel is a crucial turbofan component for transmitting rotational energy from the turbine blades to the fan and compressor.

Turbine wheels must withstand intense operation in harsh environments. There is a great deal of centrifugal pressure placed on the turbine wheel due to its high rotational speed, and the strength of its material is reduced by the high temperatures of ignited air. Turbine wheel failure could be highly dangerous if fragments of the disk penetrate the aero engine casing. As such, precise alignment of the turbine wheel when machining its key characteristics is essential to ensure the smooth operation of the wheel and, in turn, the aircraft engine.

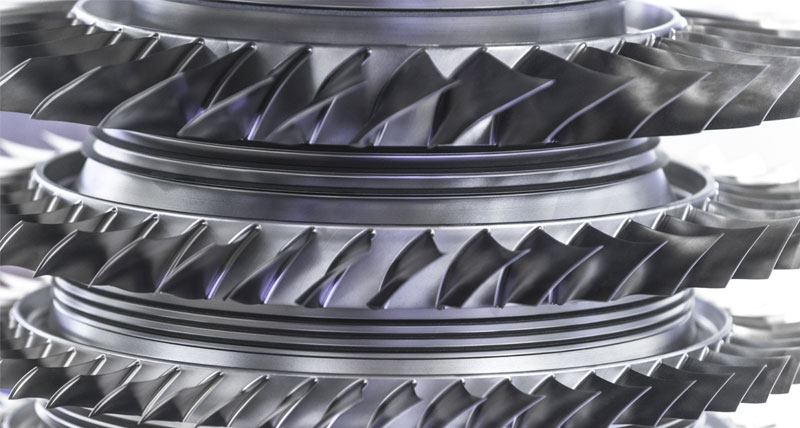

The grooves on the disk that conform to the blade root design need to ensure correct fit with the blades but also allow enough clearance for the thermodynamic expansion of the disk, which is crucial to reducing thermal stress on the wheel. Machine tool measurement is ideal for positioning the part correctly for milling to ensure that the part is finished correctly rather than finding errors after the fact and risking expensive part rejection.

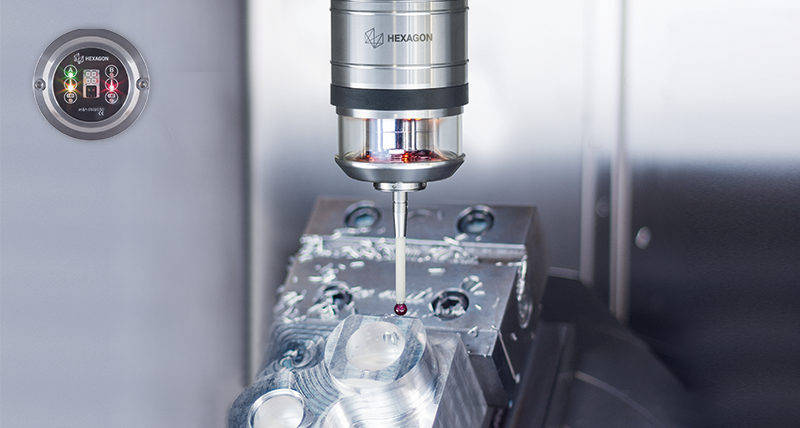

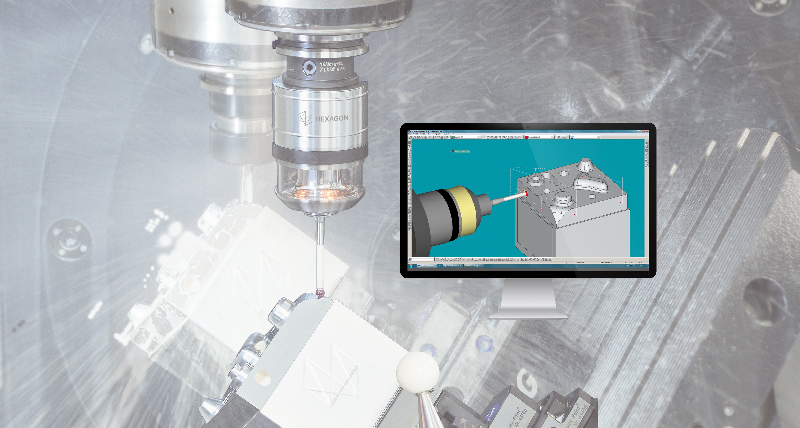

Hexagon offers machine tool probing solutions ideal for on-machine measurement of turbine wheels. A modular touch probe is ideal for measurement and alignment during part finishing, for example positioning of the finished fir-tree root for deburring. The ‘Best Fit’ functionality of Hexagon’s software solution enables zero offset and ensures the position of the machining program adapts to the actual position of the contour elements of the fir tree root profiles. The software gives confidence in the measurement results by enabling manufacturers to secure, align, and log the manufacturing process at any time between measurements of the turbine wheel in the machine tool.

Our solutions

Explore Hexagon solutions for machine tool probing for aligning turbine wheels

Infrared machine tool probes

Software for machine tool probing

Case studies

See how Hexagon solutions are used in the aerospace industry