Halving cycle times in glass bottle mould machining

How a glass bottle mould manufacturer saved significant time and costs with structured light scanning and CAD CAM machining software

Contact us

Opening its doors in 1993, this family-run shop provides much-needed glass bottle machining and repair services for glass manufacturers. Looking to reduce production cycle times and costs, Omega Enterprises turned to Hexagon 3D scanning technology and CAD CAM software to innovate machining processes.

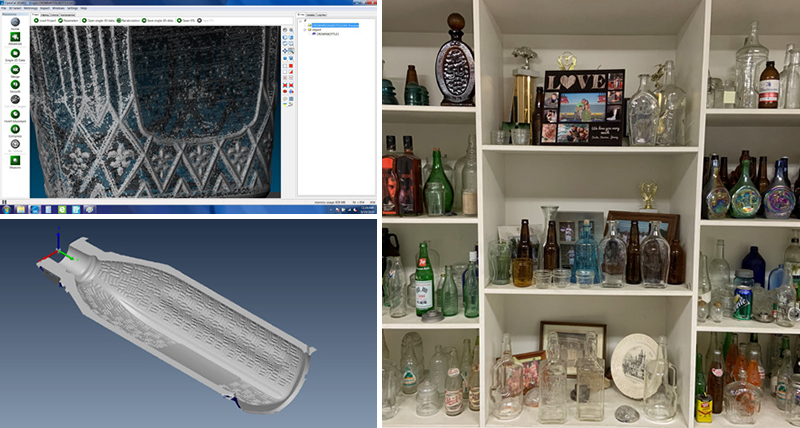

Often featuring complex artistic designs, glass bottle repair and rebuild is an intricate process. Omega Enterprises has been a stalwart of the Indiana glass industry for almost three decades, developing a specialism in this demanding high-demand application.

Given this complexity, glass manufacturers can encounter a number of common challenges that cause inefficiencies. For Omega Enterprises, tracing parts manually on an older milling machine was a significant bottleneck. “We were constantly faced with altering moulds and blanks with multiple compound angles that would require blend,” says James Jarrett, President of Omega Enterprises. “If the customer had an issue, they would modify the equipment by hand at their factory and the only way we would be able to reproduce a copy was by doing the same thing, by hand. This drove the cost up greatly. That’s when we decided to investigate a solution that could innovate our process.”

Given this complexity, glass manufacturers can encounter a number of common challenges that cause inefficiencies. For Omega Enterprises, tracing parts manually on an older milling machine was a significant bottleneck. “We were constantly faced with altering moulds and blanks with multiple compound angles that would require blend,” says James Jarrett, President of Omega Enterprises. “If the customer had an issue, they would modify the equipment by hand at their factory and the only way we would be able to reproduce a copy was by doing the same thing, by hand. This drove the cost up greatly. That’s when we decided to investigate a solution that could innovate our process.”

Speed and precision: the art of 3D scanning

First, Omega Enterprises updated its CAD CAM software. A user of EDGECAM for a number of years, the team updated to the latest version and found a number of advancements and new features. The next step was to find the right 3D scanning solution that could capture parts quickly and accurately, enabling operators to start machining sooner.

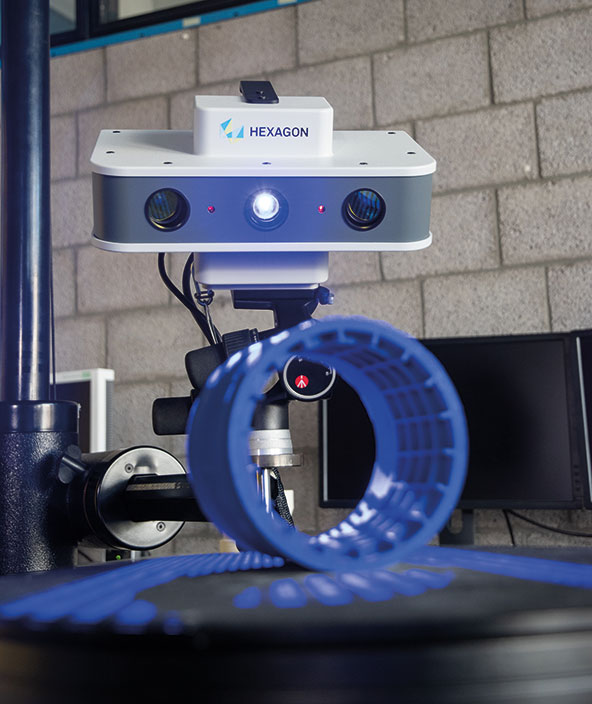

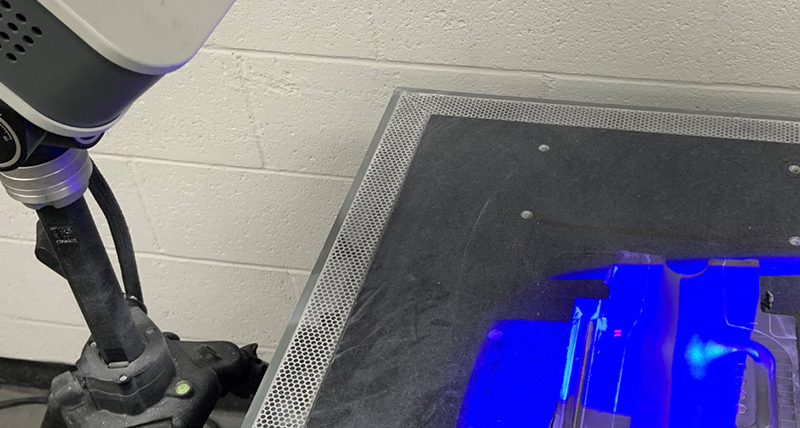

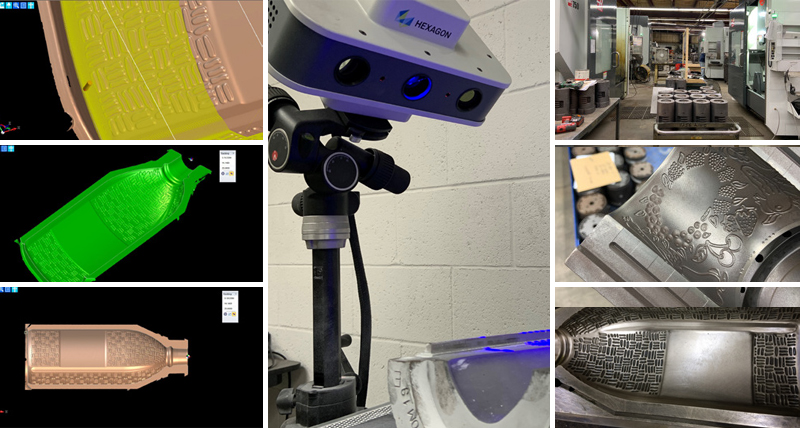

After exploring a number of options, Omega Enterprises opted for Hexagon’s PrimeScan structured light scanner. “We really like the PrimeScan because it proved to offer the highest-quality scan results for our needs,” says Jarrett. “Also, it is compact enough to take it directly to the machine on the shop floor or off-site if required. The scanner opened a big door for us because it has allowed us to be more competitive.”

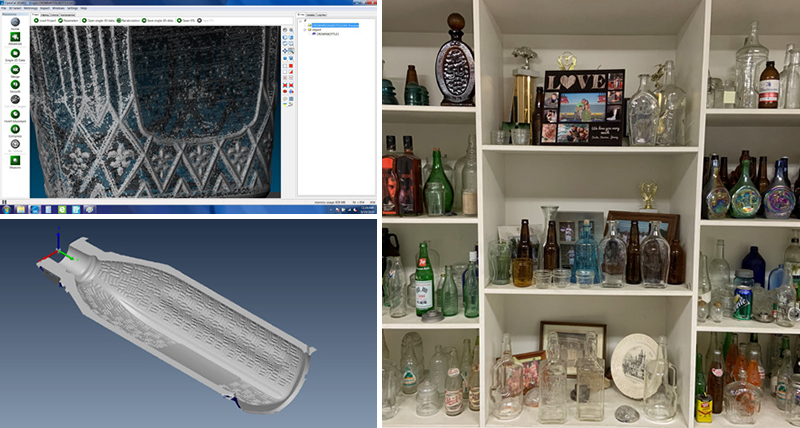

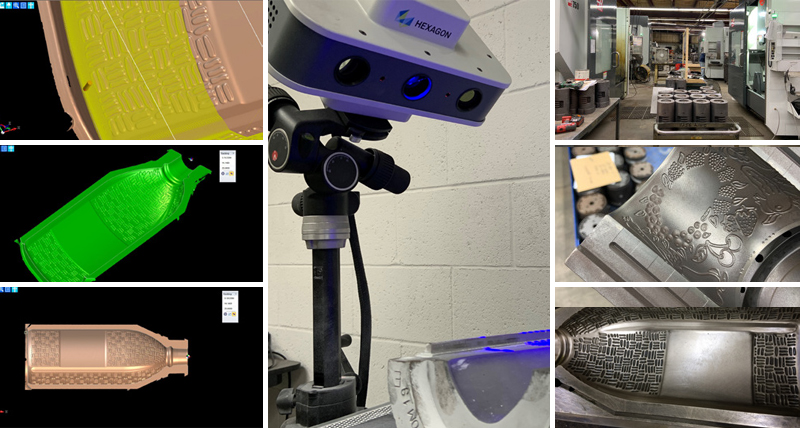

We really like the PrimeScan because it proved to offer the highest-quality scan results for our needs. The integration of the PrimeScan and EDGECAM has greatly simplified and accelerated Omega’s processes, all without the need for high-level reverse engineering. For this process flow, the PrimeScan captures a mould or blank, generates the 3D digital replica, and imports the high-quality STL file into EDGECAM. This enables Omega to create G-code directly from the STL, allowing hybrid machining and saving time by not having to convert the STL into a model or other format.

For Omega Enterprises, PrimeScan and EDGECAM have proven a perfect combination for tackling their complex parts. “The heart of our business is being able to generate machine paths,” says Jarrett. “If we can’t generate good machine paths, we can’t make parts. Many of the parts we work with are highly artistic, with no real means for someone to draw it out and get it right, never mind doing so in a timely fashion. Now we can take any highly detailed part, have it scanned, brought into EDGECAM, then put it right on the mill or lathe.”

Jarrett says that the team has reduced cycle times by up to 50 percent in some cases. “Take a basket weave part, for example. It took 40 hours to duplicate the part in our previous process. Now we are able to do all that and cut parts within half that time. There’s no way we could have done that without PrimeScan and EDGECAM.”

Jarrett says that the team has reduced cycle times by up to 50 percent in some cases. “Take a basket weave part, for example. It took 40 hours to duplicate the part in our previous process. Now we are able to do all that and cut parts within half that time. There’s no way we could have done that without PrimeScan and EDGECAM.”

The Omega Enterprises team was able to start implementing these improvements quickly thanks to the adaptability of the structured light scanner and Hexagon’s service and support. “Having the Hexagon application engineer on-site for the two-day scanner training was outstanding,” says Jarrett. “Not only did my team learn a lot from the training, but the trainer tailored the course to our particular application needs by using parts taken directly off our manufacturing floor!”

Ultimately, as Jarrett notes, PrimeScan and EDGECAM have helped transform Omega Enterprises’ competitiveness. “The high quality of the scan data provides crisp edges and great definition of any art style found on the mould. With the 3D scanner we can duplicate these highly detailed works without hesitation. It really has added a side to our business that we would not be able to do without it.”

Often featuring complex artistic designs, glass bottle repair and rebuild is an intricate process. Omega Enterprises has been a stalwart of the Indiana glass industry for almost three decades, developing a specialism in this demanding high-demand application.

Given this complexity, glass manufacturers can encounter a number of common challenges that cause inefficiencies. For Omega Enterprises, tracing parts manually on an older milling machine was a significant bottleneck. “We were constantly faced with altering moulds and blanks with multiple compound angles that would require blend,” says James Jarrett, President of Omega Enterprises. “If the customer had an issue, they would modify the equipment by hand at their factory and the only way we would be able to reproduce a copy was by doing the same thing, by hand. This drove the cost up greatly. That’s when we decided to investigate a solution that could innovate our process.”

Given this complexity, glass manufacturers can encounter a number of common challenges that cause inefficiencies. For Omega Enterprises, tracing parts manually on an older milling machine was a significant bottleneck. “We were constantly faced with altering moulds and blanks with multiple compound angles that would require blend,” says James Jarrett, President of Omega Enterprises. “If the customer had an issue, they would modify the equipment by hand at their factory and the only way we would be able to reproduce a copy was by doing the same thing, by hand. This drove the cost up greatly. That’s when we decided to investigate a solution that could innovate our process.”Speed and precision: the art of 3D scanning

First, Omega Enterprises updated its CAD CAM software. A user of EDGECAM for a number of years, the team updated to the latest version and found a number of advancements and new features. The next step was to find the right 3D scanning solution that could capture parts quickly and accurately, enabling operators to start machining sooner.

After exploring a number of options, Omega Enterprises opted for Hexagon’s PrimeScan structured light scanner. “We really like the PrimeScan because it proved to offer the highest-quality scan results for our needs,” says Jarrett. “Also, it is compact enough to take it directly to the machine on the shop floor or off-site if required. The scanner opened a big door for us because it has allowed us to be more competitive.”

We really like the PrimeScan because it proved to offer the highest-quality scan results for our needs. The integration of the PrimeScan and EDGECAM has greatly simplified and accelerated Omega’s processes, all without the need for high-level reverse engineering. For this process flow, the PrimeScan captures a mould or blank, generates the 3D digital replica, and imports the high-quality STL file into EDGECAM. This enables Omega to create G-code directly from the STL, allowing hybrid machining and saving time by not having to convert the STL into a model or other format.

For Omega Enterprises, PrimeScan and EDGECAM have proven a perfect combination for tackling their complex parts. “The heart of our business is being able to generate machine paths,” says Jarrett. “If we can’t generate good machine paths, we can’t make parts. Many of the parts we work with are highly artistic, with no real means for someone to draw it out and get it right, never mind doing so in a timely fashion. Now we can take any highly detailed part, have it scanned, brought into EDGECAM, then put it right on the mill or lathe.”

Jarrett says that the team has reduced cycle times by up to 50 percent in some cases. “Take a basket weave part, for example. It took 40 hours to duplicate the part in our previous process. Now we are able to do all that and cut parts within half that time. There’s no way we could have done that without PrimeScan and EDGECAM.”

Jarrett says that the team has reduced cycle times by up to 50 percent in some cases. “Take a basket weave part, for example. It took 40 hours to duplicate the part in our previous process. Now we are able to do all that and cut parts within half that time. There’s no way we could have done that without PrimeScan and EDGECAM.”The Omega Enterprises team was able to start implementing these improvements quickly thanks to the adaptability of the structured light scanner and Hexagon’s service and support. “Having the Hexagon application engineer on-site for the two-day scanner training was outstanding,” says Jarrett. “Not only did my team learn a lot from the training, but the trainer tailored the course to our particular application needs by using parts taken directly off our manufacturing floor!”

Ultimately, as Jarrett notes, PrimeScan and EDGECAM have helped transform Omega Enterprises’ competitiveness. “The high quality of the scan data provides crisp edges and great definition of any art style found on the mould. With the 3D scanner we can duplicate these highly detailed works without hesitation. It really has added a side to our business that we would not be able to do without it.”