Aero engine blisk inspection

Dimensional measurement solutions for the Inspection of aero engine blisks

Contact us

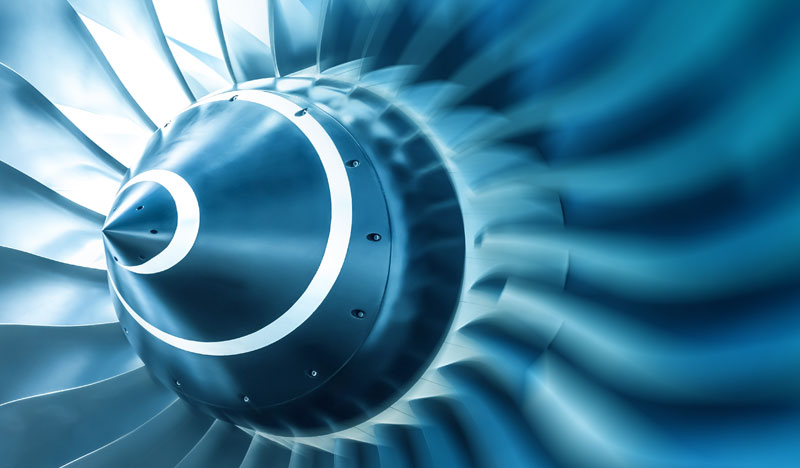

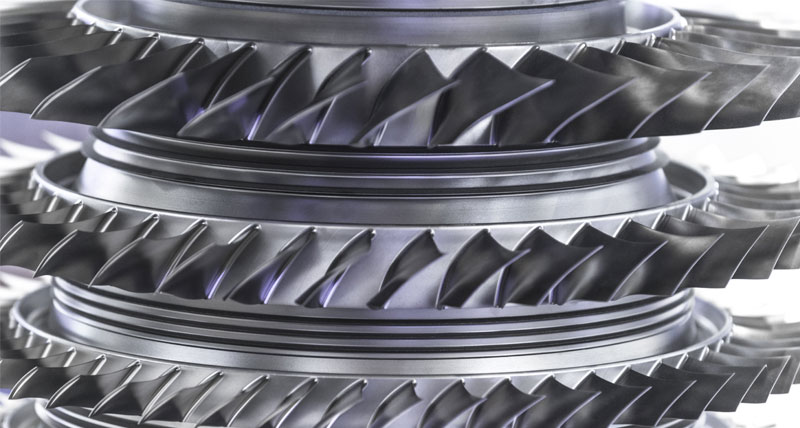

Blisks comprise blades and a rotor disk in a single, integrally manufactured part. Used in fans and compressors, blisks contribute to aero engine performance, driving efficiency and reducing energy consumption and engine noise emissions.

Highly-accurate measurement is essential to ensure that blisk features, such as the locators and fixing holes on the disk, are aligned, preventing unwanted resonances and imbalances that could impact engine performance. At the same time, the long machining cycle time for blisks makes fast inspection solutions highly desirable.

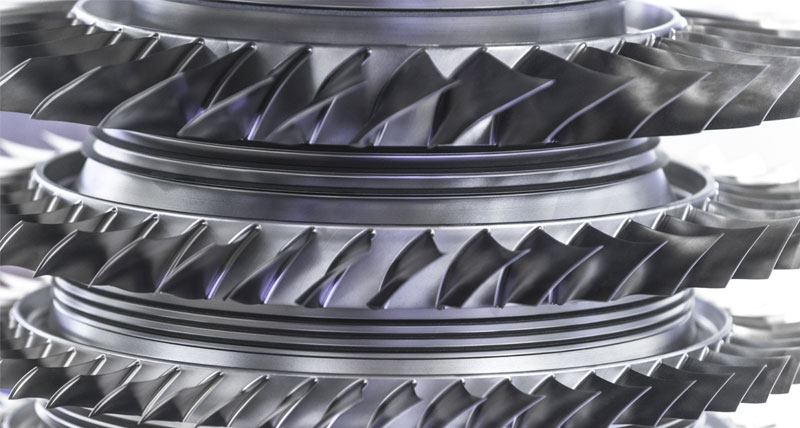

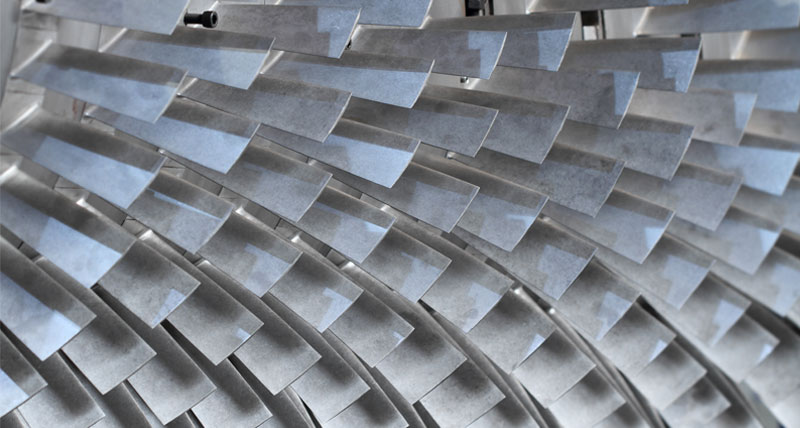

Measuring blisks is highly complicated. As well as their more standard geometries, blisks have freeform surfaces and blades with slim profiles and sharp, rounded edges. The surface profile has a tight tolerance but also might be coated, meaning traditional tactile measuring methods risk marking the part or distorting results.

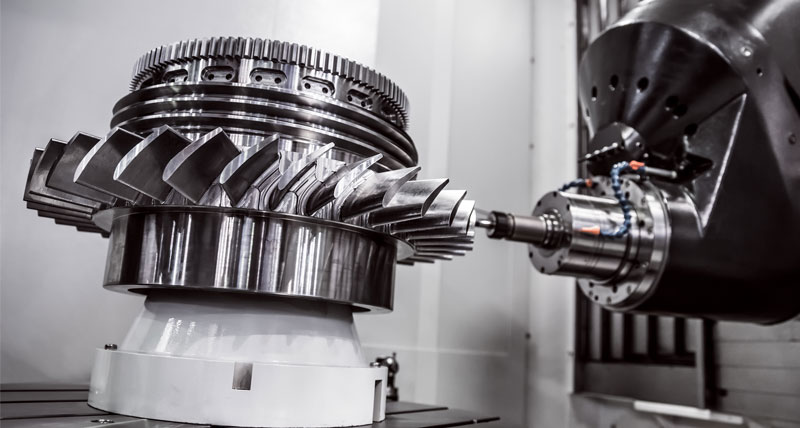

Hexagon’s combined contact and optical measurement is ideal to achieve the faster inspection cycle times and minimised measurement uncertainty required for blisks. Using a highly-precise tactile probe and rotary table on a 3D coordinate measuring machine (CMM), users can enhance part accessibility with 4-axis scanning capabilities while measuring tight tolerance blisk features with accuracy in the sub-micron range. Hexagon’s automatic sensor changing system enables optical scanning for high throughput and capturing the bright surfaces of coated or polished blisks. Gas path features such as the annulus, fillet radii and radial sections are quickly captured in continuous scanning mode.

In addition, specialised blade and blisk software enables a variety of simplified solutions for the automated measurement of special geometries and blade-specific evaluations.

Our solutions

Explore Hexagon solutions for aero engine blisk inspection

Sub-micron accuracy measurement

High throughput optical measurement

Blisk measurement software

Case studies

See how Hexagon aero engine blisk measurement solutions are used by customers