RWP20.50-G-UTP ultrasonic measurement solution

Complete solution for wall thickness measurement directly on the machine tool

Ready to get started?

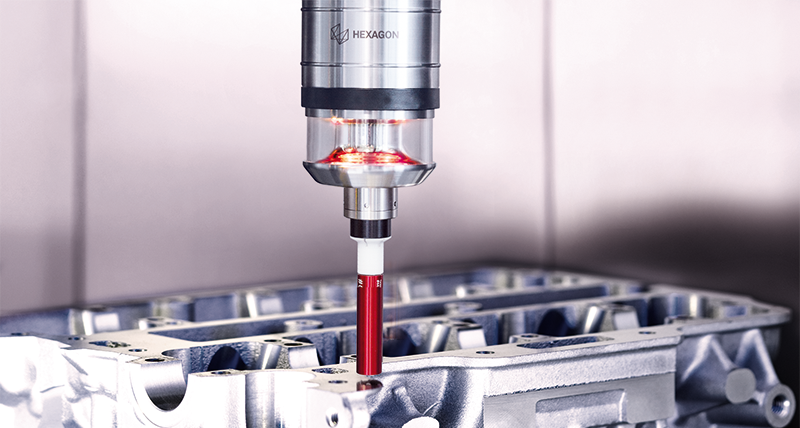

The RWP20.50-G-UTP ultrasonic touch probe makes it simple to automatically measure the thickness of the walls of larger parts directly on the machine tool, resulting in significantly faster inspections and enhanced data capture.

Measuring the wall thickness of parts manually is a time-consuming process that generates machine tool down-time. The RWP20.50-G-UTP ultrasonic touch probe transforms the procedure by using ultrasound to automatically measure wall thickness within the machine tool installation.

Supported by dedicated thickness measurement software, the RWP20.50-G-UTP is compatible with the control software for Siemens, Heidenhain and Fanuc tooling machines, making it easy to capture and visualise measurement data directly on the shop floor and to export it for use in other programs.

Integrating Hexagon’s robust, proven radio-wave technology, the RWP20.50-G-UTP operates in the 2.4GHz frequency range. Like other probes from Hexagon, the RWP20.50-G-UTP has a robust, modular design and can be converted into a dimensional or temperature probe simply by changing the measuring unit, opening it up to a wider range of applications integrated into the machine tool. And in contrast to other ultrasonic solutions, the RWP20.50-G-UTP works without any coupling fluids, which simplifies operations and helps keep parts cleaner.

Depending on the application, the RWP20.50-G-UTP works either with or without coupling fluids. The version that works with coupling fluid is available in two different measurement ranges.

Extend the possibilities of your machine tool with the RWP20.50-G-UTP ultrasonic measurement solution for thickness measurements on machine tools.

-

Features & benefits

Innovative measurement technology

Deploying ultrasonic measurement technology directly on the machine tool automates, speeds up and simplifies thickness measurements.

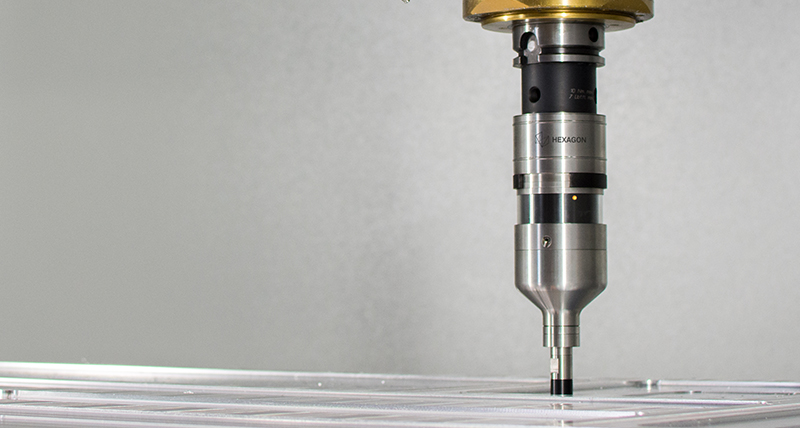

Modular and robust design

The probe can be converted into a regular probe simply by changing the measuring unit. All components are protected to IP68 standards.

No need for any coupling medium

Unlike other ultrasonic solutions, the RWP20.50-G-UTP works without any coupling fluids, which simplifies operations and helps keep parts cleaner.Wet or dry coupling

There is a choice of sensor heads, adapted to different customer requirements and applications. For wet applications, customers can opt for a sensor head with a measurement range of either 0.7 – 9 mm or 1.5 – 30 mm, using the cooling lubricant from the machine tool as the coupling fluid.

Additionally, a sensor for dry applications is available for the measurement range of 0.7 – 9 mm, which does not need any coupling fluids.Extensive report and export functions

Captured data can be viewed in the form of clear reports or can be exported for further use in data bases, tables and statistic software.

Familiar, reliable communication

RWP20.50-G-UTP communicates with the RWR95.51 radio-wave receiver, which also supports communication to tactile and temperature probes. -

Technical data

Technical data Transmission Frequency 2400-2483,5 MHz (2,4GHz) Transmission/Reception Range Up to 18 m Power supply 1x 9 V battery, block, 6LR61,

Lithium: 1200 mAh, Alkaline: 550 mAhMaterial Stainless steel, POM Weight without Shank Approx. 920 g Temperature Range Operation: 10°C - 50°C, Storage: 5°C - 70°C Sealing IP68: EN60529 Transmission pulse voltage V50 -70 V ±10% an 50 Ω Pulse rise time tr to 5 ns Pulse fall time tf 2 to 5 ns Pule length td 100 ±5 ns Effective output impedance 8 Ω ±20% Equivalent input impedance 50 Ω ±18% Nominal frequency range 1,0 to 30 MHz (-3 dB) Measurement or pulse repetition frequency 500 Hz Sensing Directions -Z Maximum Stylus Overtravel -6 mm Trigger Force 12 N Recommended Probing Feedrate 500 mm/min Measuring accuracy* ±10 µm (at 47.10-UTP-D-0.7-9) Measuring Range (aluminium) 0.7 - 9 mm (47.00-UTP-D-0.7/9)

0.7 - 9 mm (47.00-UTP-W-0.7/9)

1.5 - 30 mm (47.00-UTP-W-1.5/30)Maximum Battery Life with Lithium Battery at

5% ProbingOperation: 200 h

Standby: 1 year

* The measuring accuracy depends on the condition (surface finish, surface parallelism) and calibration of the workpiece.

-

Downloads

-

Buy machine tool accessories online

Buy Machine Tool accessories online

Identify your spare parts with confidence and benefit from fast UPS delivery -

Related informationRWP20.50-G – The modular probing system

The modular, bidirectional probing system RWP20.50 can be used for a range of applications. It can be easily modified by simply screwing in various measuring units. Extensions and cross-probes can both be used.

Reliability and precision are the key to consistently high quality with optimised processing times. Due to the fact that the RWP20.50 can be used as a probe, a temperature sensor and a ultrasonic-probe, the warehousing costs for replacement devices are much lower than for separate device types. This is another advantage, particularly in lean production.

Hexagon’s probes fulfil all requirements in the machine tool in tried and tested fashion. Extreme accelerations, high positioning speeds, constant vibrations, hard tool changes, increased temperatures and coolants pose no problems for Hexagon’s touch probes. The precision mechanics can continue to switch without wear and extremely precisely for years under all these conditions.