What is HxGN Visual Detection?

HxGN Visual Detection is an automated surface inspection application ideal for defect detection.

Product enquiry

HxGN Visual Detection

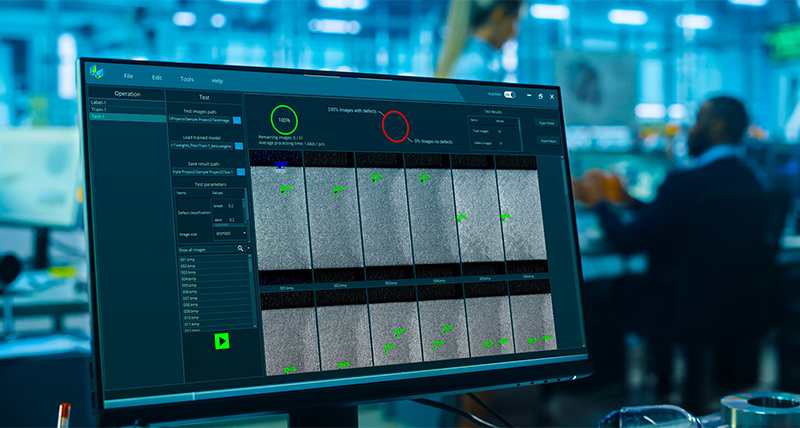

HxGN Visual Detection is an automated surface inspection application capable of detecting defects across a wide range of materials such as glass, metal, plastics, ceramics and textiles. It uses advanced AI to quickly learn from just a few sample images featuring a range of defects. The software can be deployed to support a wide range of use cases and can manage high-speed throughput within a large manufacturing cell or when checking small numbers of high value components during a proof of concept.

Create new inspection plans in just a few clicks via an intuitive, user-friendly interface based on Hexagon’s common UI design. Quickly draw rectangles or polygons around defects in training images and apply labels. Access quality reports for full details on defect location, size and classification. The HTML formatted quality reports are easy to share with colleagues and stakeholders.

Beneath the surface

Surface is the primary indicator of quality. The cost of poor quality (CoPQ) is a constant issue for many manufacturers. Product recalls and rework impact revenue. Brand reputation and commercial relationships suffer when businesses fail to detect surface defects.

Setting up a vision system to identify scratches or flaws often mandates expensive projects and bespoke coding to configure the system for a specific part. HxGN Visual Detection significantly reduces the time and costs associated with establishing quality control checks by harnessing the power of machine learning to quickly understand the difference between normal and abnormal surfaces, and then identify them in-line, near-line or off-line.

In any industry or application where surface integrity or surface finish is essential, HxGN Visual Detection gives you the automation, accuracy and speed to reduce waste, improve profitability and stay ahead of the competition.

- Reduce waste by correcting errors faster

- Fast to deploy, easy to train

- Flexible to meet specific manufacturing needs

- Simple to use, with minimal operator training

- Rapid quality control with machine learning powered defect identification

- Integrated with an existing ecosystem of Hexagon products

- Fully automatable for custom integration to production systems

-

Features & benefits

Increased production speeds

Whether put to work in the quality room or installed on the factory floor, HxGN Visual Detection delivers faster quality control throughput by automatically detecting surface errors and anomalies at speed. The machine learning process is simple and guided. New products can be added to a manufacturing cell quickly with little involvement from product specialists or quality engineers.

Flexes for a wide range of use cases

Thanks to convolutional neural network (CNN) machine learning, HxGN Visual Detection can be trained to recognise target defects present on a wide range of materials. Automated quality control checks can be quickly configured for many components commonly used in consumer electronics, computing, aerospace, medical and automobile manufacturing. Monitor high-speed throughput in-line within a large manufacturing cell or when validating small batches of high value components during a proof of concept.

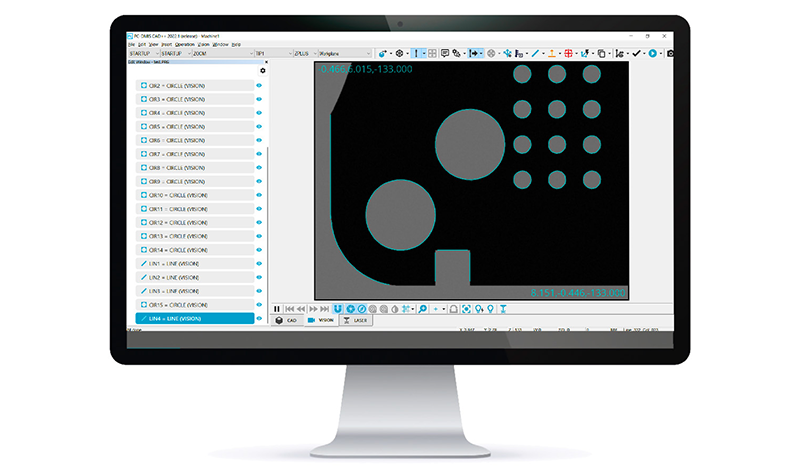

Plug into your existing Hexagon metrology workflow

HxGN Visual Detection is part of a wider ecosystem which embraces automated quality processes for smarter manufacturing across the business. It is ready for use with Hexagon’s Optiv vision CMMs and can be incorporated into PC-DMIS measurement workflows to increase autonomy, accuracy and efficiency.

Integrate to automate

Go for simple or sophisticated. HxGN Visual Detection can be easily added into any production system as a standalone application which monitors a directory of images for analysis. Alternatively, it can be integrated with third-party applications via an API to create a fully automated surface detection system.

-

Technical data

- Works with PC-DMIS and OPTIV vision CMMs: Add surface inspection to your Hexagon metrology workflow.

- Fast set up and configuration: Off the shelf setup with no coding required.

- Choose from a range of CNN models: Choose the most useful machine learning model for your application.

- Built on YOLO (you only look once) CNN principles: Leading neural network for fast object detection.

- Image deformation, normalisation and filtering algorithms: Advanced image analysis for accurate defect detection.

- Easy to use hyperparameters: Fine-tuned image analysis without coding.

- Integrated with local GPU: Direct access to computer processing power for high-speed rendering and detection.

- Quality reports: Easily access and share reports via convenient HTML format.

- Easy to integrate with dimensional analysis systems: Incorporate into vision CMM and other metrology workflows via Bridge application.