Operate and Maintain

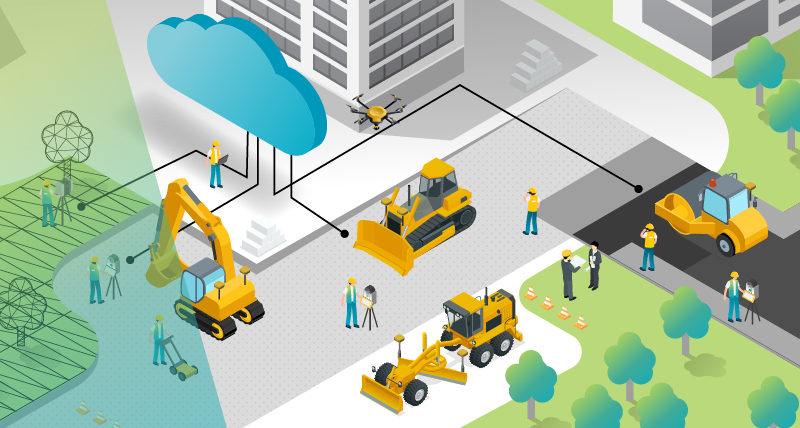

Monitoring infrastructures properly requires continuous reliable, real-time data that assesses if structures are performing safely and efficiently.

Increase the lifetime value of your infrastructure

Structures last longer when they’re well built and well taken care of. Heavy construction projects need to be regularly monitored to ensure operational safety. Regular monitoring also enabled effective management of project progress and asses any potential impacts on the environment.

Long-term monitoring ensures the stability of existing structures. This maintenance looks at the impacts of ageing, as well as the potential effects coming from nearby construction activity, seismic activity and other natural hazards.

A proactive maintenance strategy with routine and preventive maintenance schedules will also help extend the lifespan of assets by ensuring servicing is done when due.

The best maintenance strategies for heavy construction

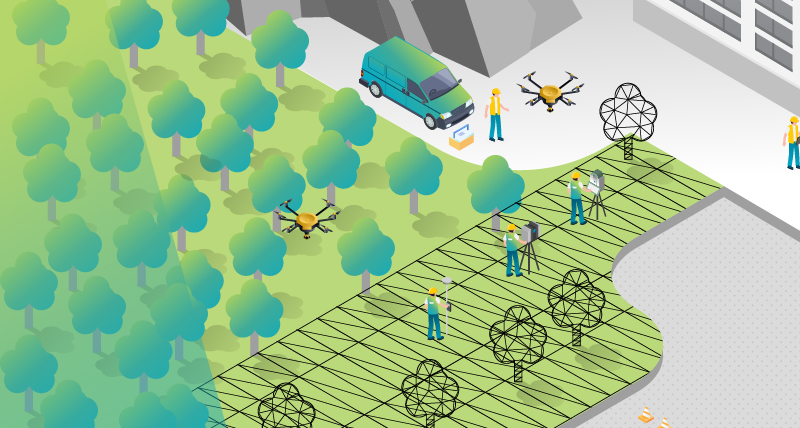

Every construction project is unique, with different maintenance needs. To help shape your operate and maintenance strategy consider:

- If the technology is versatile and flexible for your projects requirements (keeping safety, performance and sustainability in mind)

- Preventative maintenance to increase lifetime value of your infrastructure by regularly capturing the conditions of your built assets

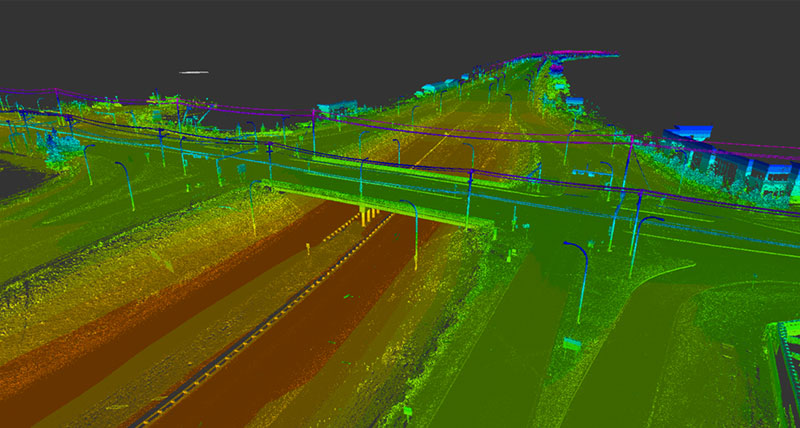

There are a wide range of solutions you can choose from. Most heavy construction projects use a variety of survey methods such as total stations, GNSS, terrestrial laser scanning or mobile mapping. These tools are used for all types of projects to review potential dilapidation, asset management, crack detection and various machine learning applications.

Learn more about the best operate and maintenance approaches below: