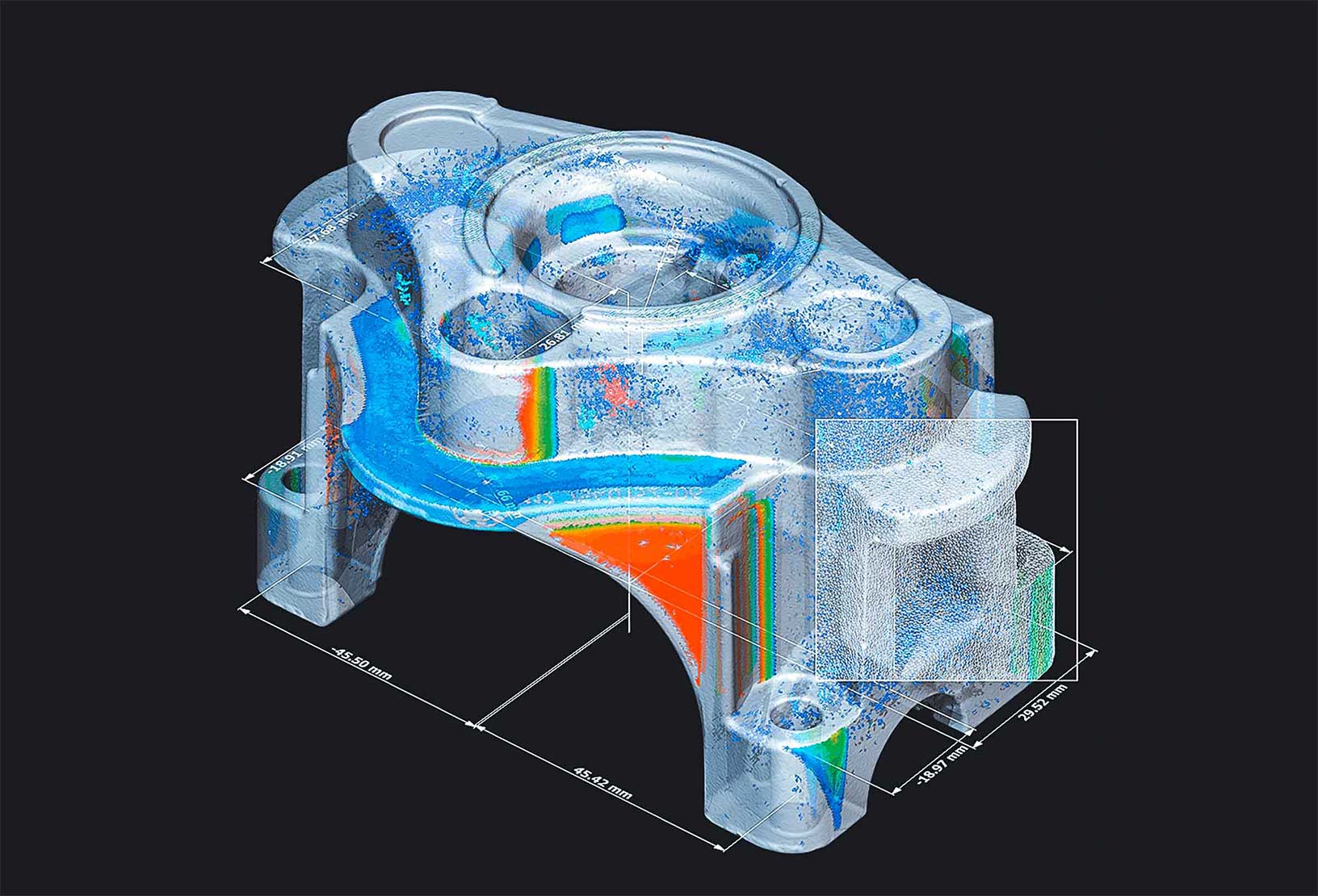

CT analysis

Go under the surface and analyse unseen details with industrial computed tomography (CT) analysis.

Look beyond dimensions with CT analysis software

Volume Graphics, part of Hexagon, provides software for industrial computed tomography. Learn more about CT analysis.

What's on the inside matters. By accurately representing both outer surfaces and inner structures, CT analysis of X-ray images offers unique insights into product quality, from the surface to the core, for non-destructive testing and other applications.

Overview

Industrial computed tomography (CT) scanning offers manufacturers unique insight into their products. X-ray technology captures 2D data from both outer surfaces and internal structures in multiple slices. CT analysis software can reconstruct this 2D data into 3D voxel data, providing a comprehensive 3D visualisation of the scanned object. Advanced CT analysis and visualisation software then enables a range of applications, including measurement, defect detection, mesh creation and simulation, that provide a complete understanding of the product and its structures.

Hexagon’s CT analysis software provides a non-destructive testing solution that offers value throughout the manufacturing process from design prototyping to inline testing and quality assurance. The benefits of CT analysis are particularly relevant for the analysis of parts with complex internal features, those made from materials prone to porosity and other internal defects, and parts produced by additive manufacturing.

$ProductName

$SustainabilityImpactLabel

$SustainabilityCTABandHeadingLabel

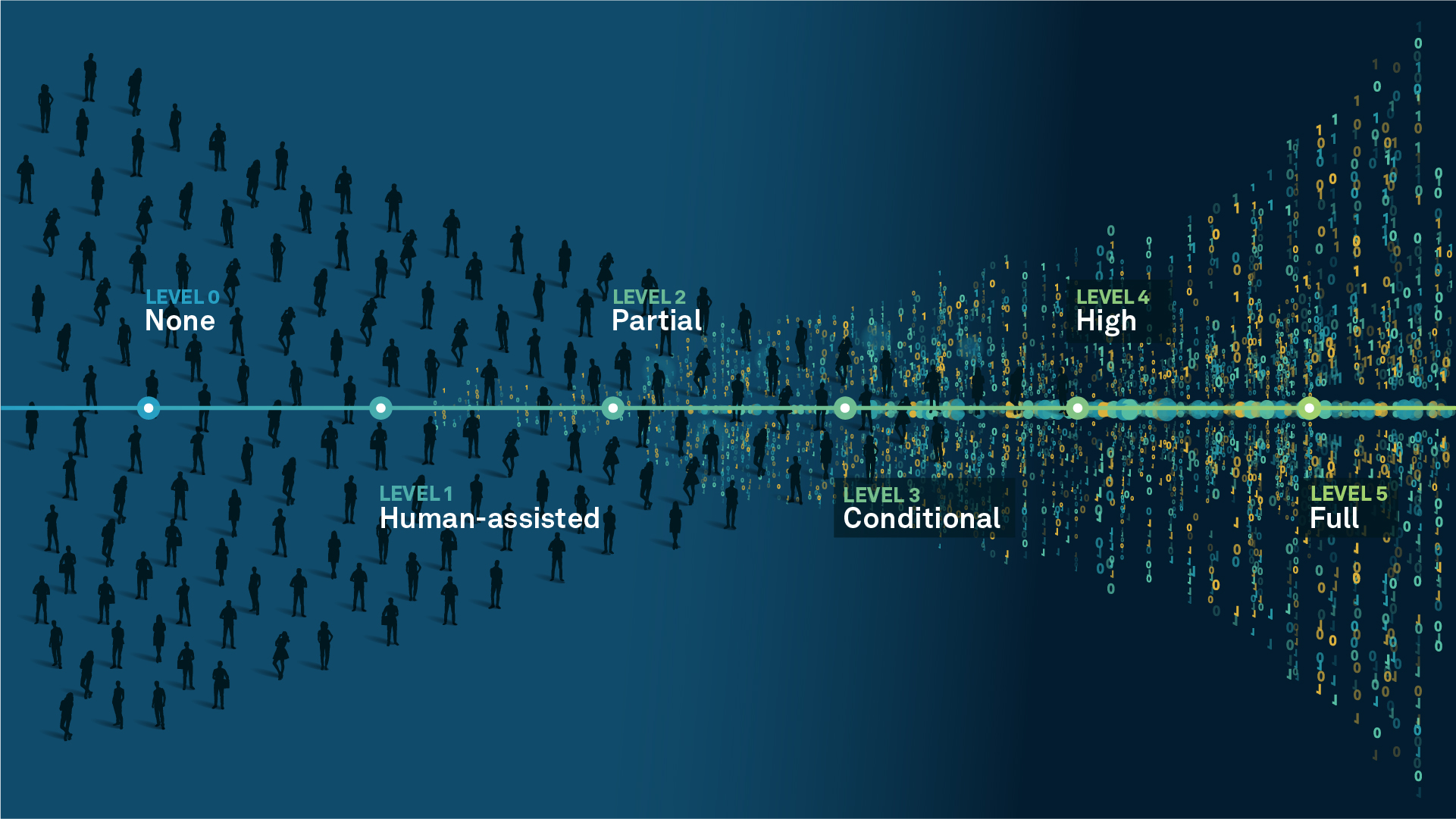

We’re climbing the automation curve

Our transition to Intelligent automation is accelerating. Ultimately, our innovations will give rise to new technologies and applications - many of which we’ve yet to imagine. Today, every Hexagon solution is mapped and tagged according to its level of automation, so customers can clearly track our progress towards the freedom of autonomy.

Human-driven

All tasks completed by human labour; no data is leveraged across the operation.

Human-assisted

Labour is primarily conducted by a human workforce. Some functions have been automated to simplify control.

Partial automation

Some tasks are automated for short periods of time, accompanied by occasional human intervention.

Conditional automation

Human workforce is used for intervention as autonomous operations begin to increase productivity.

Highly autonomous

Autonomous systems complete required tasks within specific bounds, unleashing data and building smart digital realities.

Full autonomy

A smart digital reality™ enables autonomous systems to complete all tasks without human intervention.

Land

Products that make an environmental impact in forest monitoring, material reusability, farming or water usage.

Air

Products that make an environmental impact in renewable energy, noise pollution elimination and e-mobility.

Water

Products that make an environmental impact in saving our oceans, reducing pollution and increasing access to clean water.