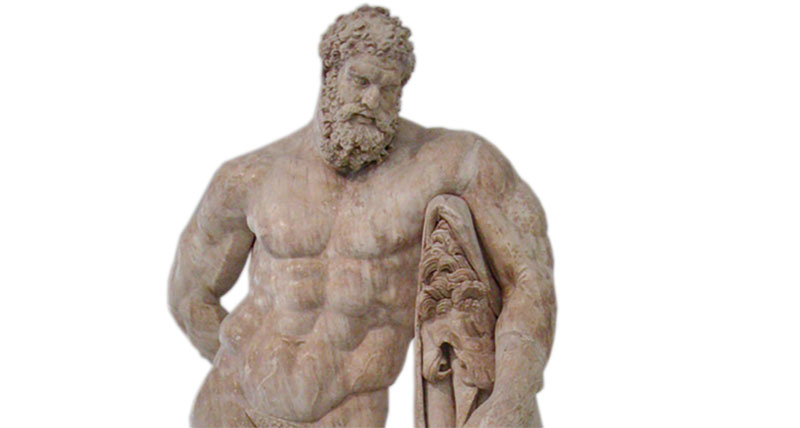

The “Weary Heracles”

Boston Museum of Fine Arts - USA

Contact us

An extraordinary story lies behind a broken “Weary Heracles” statue made of marble whose lower and upper part have been in two geographically opposing parts of the world for decades. The objective of a 3D scanning project in 2005 was to digitally record both parts of the statue and to combine the respective 3D models on the computer.

Objective and measuring object

The original larger than life-size bronze statue of the Greek demigod Heracles was created approximately 330 - 320 BC by the Greek master Lysippus of Sicyon. Because of his unusual posture of repose, it is generally referred to as the “Weary Heracles” statue. A replica made of marble was found in two geographically totally different parts of the world. To date, the questions of time and circumstances for the cause of the damage have not been able to be solved.

The upper half of the statue was acquired by the Boston Museum of Fine Arts (USA) in 1981; the lower part is on display in the Antalya Archaeological Museum (Turkey). The objective of the scanning project was to digitally capture both parts of the statue and to merge the digital models. This way, at least a complete virtual model of the statue would be available to be viewed and analysed. Unfortunately, the Boston Museum denied the access to the upper part for a digitisation at that time. With the assistance and cooperation of the Antalya Museum and the Turkish authorities, at least the bottom part of the statue could be fully digitised.

The upper half of the statue was acquired by the Boston Museum of Fine Arts (USA) in 1981; the lower part is on display in the Antalya Archaeological Museum (Turkey). The objective of the scanning project was to digitally capture both parts of the statue and to merge the digital models. This way, at least a complete virtual model of the statue would be available to be viewed and analysed. Unfortunately, the Boston Museum denied the access to the upper part for a digitisation at that time. With the assistance and cooperation of the Antalya Museum and the Turkish authorities, at least the bottom part of the statue could be fully digitised.

The project was carried out by our sales partner Info(+)TRON in cooperation with the Division of Photogrammetry (Yildiz Technical University, Turkey), the Institute ‘Photogrammetry and Remote Sensing’ (ETH Zurich, Switzerland) and the company Breuckmann.

Measuring system and setup

The 3D digitisation of the statue’s lower part was carried out in September 2005 at the Archaeological Museum in Antalya. A preceding model to the white light scanner AICON SmartScan was chosen for this scanning task. The system is especially designed to fulfil the demanding requirements involved in the three-dimensional data acquisition of objects and structures in arts and cultural heritage: They not only deliver precise 3D models at a prime level of resolution and accuracy, but moreover allow for texture mapping of the object surface in the object’s authentic colour.

The 3D scanner consist of a sensor bar fitted with a projector unit and a colour camera (in this case 1.4 megapixels) mounted on a tripod, a calibration plate, and a control unit. Lenses covering a field of view of 489 x 360 mm were chosen from the flexible adjustable measuring fields for this project, resulting in a lateral and depth resolution of approximately 360 µm and 20 µm, respectively.

Workflow

With the statue featuring numerous concave and hidden areas, the positioning of the scanner as well as the arrangement of the scan overlay required careful preparation. For the digitisation of the lower part of the “Weary Heracles” (height around 1.1 m), a total of approximately 60 scans (83.75 M points at a spacing of 0.5 millimetres) were taken during one and a half working days.

With the statue featuring numerous concave and hidden areas, the positioning of the scanner as well as the arrangement of the scan overlay required careful preparation. For the digitisation of the lower part of the “Weary Heracles” (height around 1.1 m), a total of approximately 60 scans (83.75 M points at a spacing of 0.5 millimetres) were taken during one and a half working days.

Upon completion of the scans, the AICON software OptoCat was used for the alignment of the single scans and the data post-processing. OptoCat offers a variety of powerful post-processing functions, e.g. for the generation of a combined polygon mesh from single scans (merging), calculation of cross-sections, data reduction and compression, filtering and filling of holes and gaps, or the addition of texture information based on separately captured images. The recorded 3D data is visualised in a shaded format (optionally with overlapping texture or colour information) and saved in standard file formats, such as STL or PLY. OptoCat’s “Texture Mapping” module allows for geometry and image data to be stored together as OBJ format.

Conclusion

The 3D documentation of cultural heritage is increasingly gaining in importance. For these projects, the AICON Scanner offer a non-contact three-dimensional image capturing method at highest level of accuracy which is also suitable for delicate objects. Also in the case of finds which must be kept in a climate chamber, the precise 3D data allows for comprehensive scientific research while at the same time ensuring protecting the original.

The 3D documentation of cultural heritage is increasingly gaining in importance. For these projects, the AICON Scanner offer a non-contact three-dimensional image capturing method at highest level of accuracy which is also suitable for delicate objects. Also in the case of finds which must be kept in a climate chamber, the precise 3D data allows for comprehensive scientific research while at the same time ensuring protecting the original.

The processing results with an accuracy level of about 50 µm fully complied with the performance requirements of the scanning system. Various software packages were used to carry out the modelling steps, each of which providing particular functions and advantages.

The digitisation of the statue’s lower part provides scientists with the opportunity to study and document its structures and characteristics without the need to access the original.

After the two original halves of the statue were finally reunited in 2011, fund raising is planned for a subsequent 3D scanning project with the focus on also digitally completing the “Weary Heracles”.

Our special thanks go to Prof. Dr. Orhan Altan for his support especially in the initial phase of the project. We would also like to thank the Antalya Archeological Museum for their kind permission and assistance to scan the lower part of the statue as well as the Visual Computing Lab of ISTI-CNR for providing their Weaver software for the texture mapping.