Pioneer in wire technology

Kokinetics deploys tube measuring system for measuring bent wire parts

Contact us

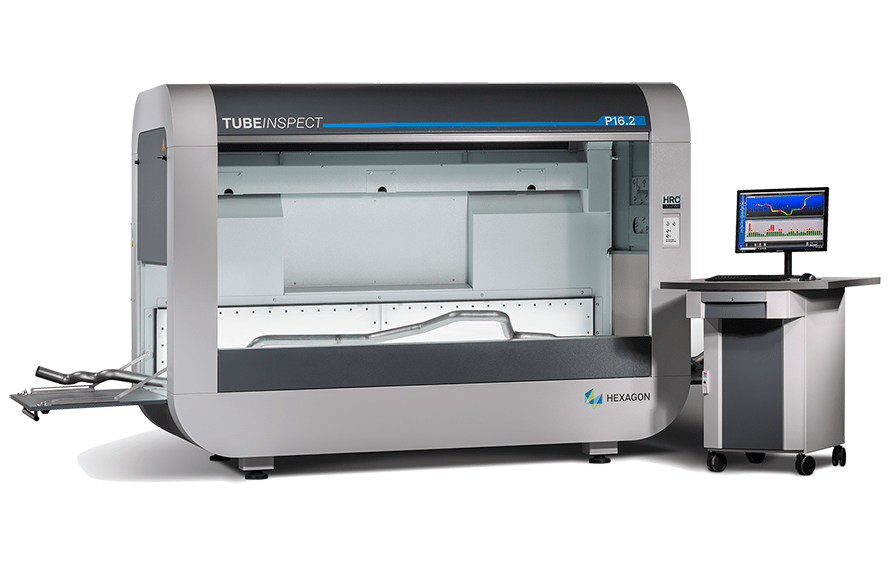

Can wire be measured using a tube measuring system? This was the question hanging in the air in 2007 when Kokinetics GmbH was considering the procurement of an optical tube measuring system as an alternative to their conventional gaging checks. The question was quickly answered with a clear “Yes”. Kokinetics purchased a TubeInspect S optical measuring system and since spring 2008 the system has proven successfully in the routine testing of bent wires, making Kokinetics a pioneer in wire bending industry.

A company with a future

Kokinetics GmbH, based in Kriftel near Frankfurt on the Main, can look back on a long and successful company history. Founded in 1890, the company made a name for itself after World War II as supplier to the aviation industry and as a tool manufacturer. The company gradually developed a concentration on the automotive sector following its success in the product categories of seat structures, seat mechanics, transmission parts, hinges and locks. Today Kokinetics has a workforce of 250 employees. From product development to prototype construction, tool manufacturing and jig making all the way to series production, every division relevant for production is operated directly in the company.

Kokinetics’ global customer base - including seat manufacturers like Johnson Controls and Faurecia and big automobile corporations like Volkswagen, General Motors and Audi - all rely on the high quality of Kokinetics products.

Expensive gaging routines are outdated

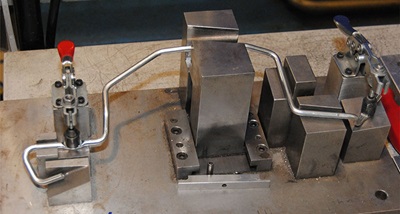

A high standard of quality coupled with optimum flexibility is essential for competitive viability as a supplier to the automotive industry. Quality checks in the past relied on mechanical gauges into which the bent wires were placed and visually checked. However, as even slight changes in geometry make readjustment of the gauges necessary, this checking routine is inflexible and cost-intensive. A major contract for seat mechanics was acquired in 2007, which led Kokinetics to consider installing an innovative and, above all, flexible checking concept.

Harald Helling, production manager for the wire division, remembers: “The fundamental issue was: Do we invest in the tried and tested, or in the future? The traditional gauges for the new products would require an investment of approximately 90.000 €, plus numerous ongoing expenses for product changes and storage costs. So we simply had to come up with something completely new.”

And Kokinetics found it in TubeInspect, the optical tube measuring system from AICON. But wire is not the same as tube. Compared to tube bends, the bent wire components required adherence to tighter tolerances: 0.5 to 0.3 mm! Nevertheless, through intensive discussions and scores of comparative measurements, AICON was able to demonstrate its capability to measure wire in a tube measuring device. Moreover, the new technology even delivered an additional advantage: it supports readjustment of the wire bending machines with the calculated correction values. As a result, set-up times can subsequently be drastically reduced.

Quality control 24/7

TubeInspect S has been in use at Kokinetics since the spring of 2008 and has contributed substantially to reducing production costs. The manufacture of the bent parts with the three CNC bending machines, which include a Robomac made by Latour (today Numalliance) and a Macsoft F37 from Numalliance, is done in three shifts. The machines are in operation around the clock: 24 hours a day, 7 days a week. This means continuous operation for TubeInspect as well.

Checking the parts with the optical measuring device is easy. For non-contact measurement of the geometry, the wire to be measured is simply placed in the measuring cell.

TubeInspect only needs a few seconds to scan the component with high-resolution digital cameras and evaluate the test specimen. If a bent wire fails to meet specifications, the deviations are reported by the TubeInspect software and subsequently analyzed. The correction values calculated by TubeInspect are then transmitted to the bending machine. Set-up or readjustment of the bending machine is accomplished in seconds! With an average of up to five product changes per day, the savings in time and costs for Kokinetics is thus substantial. Valentin Medvedkins and Oleg Sjasin, who have been operating the TubeInspect S since 2008, agree: “Back then, setting-up the bending machine was a complex process, and the manual gauging test was really time-consuming. Thanks to TubeInspect, testing goes very fast and set-up and readjustment of the CNC bending machines is done in the blink of an eye. Everything become much easier!”

TubeInspect: An all-around carefree package

TubeInspect S, owing to its wide range of possibilities and user-friendliness, has led to a streamlining of the entire production process at Kokinetics. From setting-up the bending machines before start of production, to quality control for series production, all the way to the transmission of correction data to the bending machine without interruption to production – TubeInspect S is distinguished through its enormous time-saving benefits. Past doubts have given way to the conviction that the path taken has assured the future viability of this branch of production. Harald Helling puts it in a nutshell: “Procuring TubeInspect was simply a very good decision.”