Optimising sunroof performance

Understanding the impact of design changes on the performance of electro-mechanic products

Contact us

Staying ahead in electronics demands regular design updates to existing products. But changes to electro-mechanical products that combine multiple components can have an unforeseen impact on functionality once a part is manufactured. Material modelling plays an important role in investigating and predicting how the introduction of new materials or components impacts the overall behaviour and performance of electro-mechanical products – without the need to build multiple physical prototypes.

So, when Inteva faced a challenge in designing the ground cable retention feature of a sunroof motor it turned to MSC’s Digimat coupled simulation software to resolve it.

Inteva has combined innovation and high quality to become one of the leading global suppliers of engineered components and systems for the automotive industry. Its areas of expertise include low-mass, low noise, high-performance motors and electronics to support window lift systems, seats, roof systems, glove boxes and cargo covers.

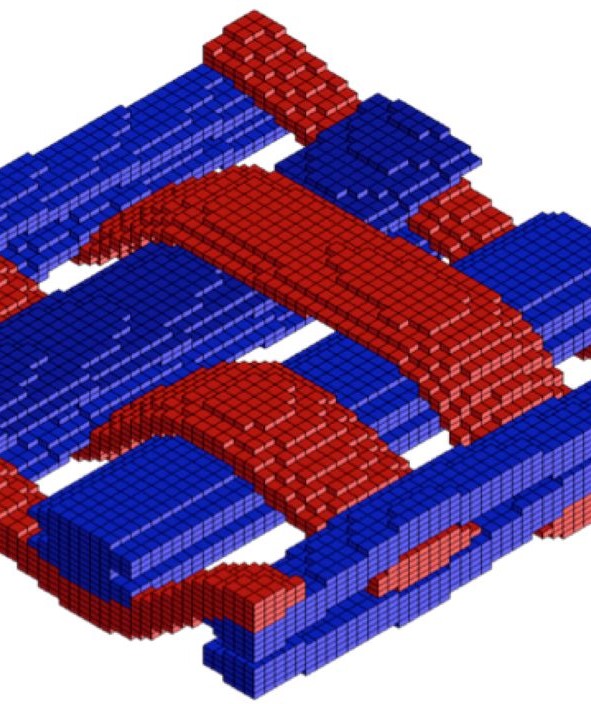

To guarantee that a sunroof motor functioned optimally, Inteva needed to ensure the retention cable remained in constant contact with the stator-can. This involved evaluating the strength of the retention feature during its assembly with the stator-can. But its strength was influenced by the orientation of fibres in the glass-filled components, making it difficult to capture and test. With Digimat coupled simulation software Inteva was able to undertake extended FEA (finite element analysis). The result was an optimal retention cable design and a smooth-functioning sunroof.