Gear manufacturer by tradition

BP Riduttori – Italy

Contact us

Experience, specialisation, product customisation – these are the three mainstays of BP Riduttori, a family-owned company based in the province of Venice. A small company but one with great technical expertise, for years many renowned companies in the transport, railway and pharmaceutical industries have relied on BP Riduttori to supply a vast array of gears and gear teeth.

The company, established in 1968, manufactures high-quality gears and gearboxes. Over time it has developed and consolidated an in-depth expertise in the manufacturing of gears based on a customer’s drawing or on a sample, often producing small lots rather than large batches.

This is the reason that BP Riduttori products are extremely diverse and cover a wide range of different gears, from the most common spur gears and helical gears to Gleason spiral bevel gears, differential reduction gears, bevel gears, worm screws, drive shafts, gearbox speed multipliers, angled gear units and worm screw jacks.

Federico Bortolami, second-generation owner and technical director of the company explains: “The applications of gears in the real world are extremely varied and although gears may meet specifically defined requirements, they are subject to a good deal of variation. When the kinematic system that the gear is a component of has relatively simple characteristics, you can use off-the-shelf gears. However, as the system gets more complex and accuracy requirements get higher, dedicated gear profiles and couplings become necessary. They allow the correct, efficient and effective transmission of motion and minimise the wear, noise and loss of precision. As a result, the mechanical designer will create the gear geometry as a function of the characteristics of the machine that is going to hold the gear, not vice-versa. From the most traditional but more and more demanding applications for powertrains through to high-accuracy machines for the pharmaceutical industry, to gyro control mechanisms, each of them has different characteristics and requirements. “Our company did not want to step on the throttle with mass production. On the contrary, we wanted to make our experience of over 40 years available to those who require specialised components and consultancy at the design and manufacturing stage. We often support the technical departments of our customers to assess the best solution as early as the design stage. Less frequent, but not uncommon, are cases in which we have to reproduce and possibly alter existing gears whose geometric characteristics or mathematical models are unknown, and real reverse engineering is therefore required.”

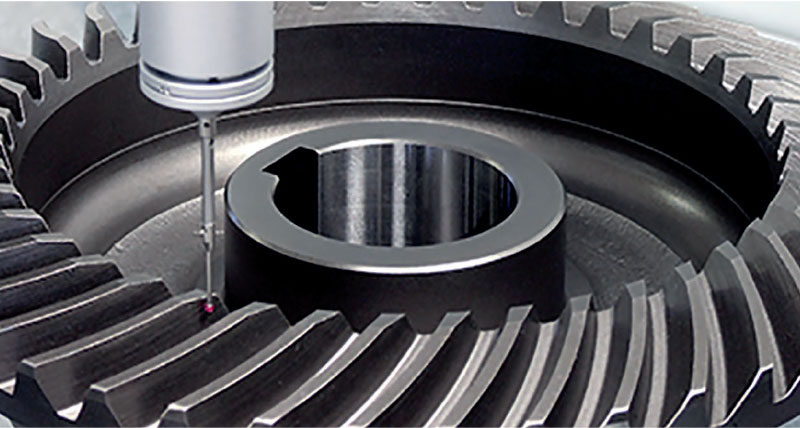

As a solution to their dimensional inspection challenge, BP Riduttori recently purchased a DEA Global Silver 9.12.8 coordinate measuring machine, equipped with a TesaStar-sm indexable probe head, a Leitz LSP-X1 continuous scanning sensor and QUINDOS 7 software. Bortolami said: “Before acquiring a measuring machine, we used traditional measuring tools and equipment. These were certainly very reliable, but less effective on the other hand, and sometimes they struggled to provide an overall evaluation of not only gears but also drive shafts, slots and bearing seats. Opting for a tool like a measuring machine has therefore been the obvious choice. Our DEA Global Silver has a comprehensive range of equipment as regards to both sensors and software. We have a continuous scanning sensor, which is essential for the accurate probing of profiles. It is attached on an indexable head, allowing repeatable orientation in hundreds of positions in space. This enables us to access and measure even the most complex gears. With the high degree of specialisation in the field, we’ve opted for the QUINDOS measurement software, complete with several application modules dedicated to the various types of gears. This gives us a full detailed analysis of every gear type and allows us to generate inspection reports that go with our products and certify their quality. We can also rely on Curve Analyzer, a very useful application package for the quick analysis of the 2D profiles that are typical of our daily work”

The measuring system supplied by Hexagon Metrology supports various stages of the manufacturing process for the BP Riduttori gears. Some measurements are performed on drive shafts and bearing seats after the turning operations that are carried out before the gear teeth are cut. After machining and final processing of the gear teeth there is the metrological sampling of the lots, and in case of very particular gears or limited quantity runs, the certification of every individual part. The QUINDOS software and its application modules have been created with attention to the specific requirements of gear manufacturers, and this is apparent,” Bortolami continues, “It is unlike other more general packages, which require more processing and are not always capable of providing all the results we need. Moreover, a measuring machine is a general purpose tool that allows you to inspect not only the gear tooth characteristics, but also the geometry of drive shafts and wheels – all with a single system.”

The staff have gradually learnt how to operate the measurement system with one-on-one training from skilled Hexagon Metrology engineers. Bortolami goes on: “The measuring machine and the control and inspection software are very easy to use, but our applications are often rather complex and above all very varied. The advice provided by the Hexagon Metrology application engineers has been essential for us. They’ve helped us to better define methods and strategies for measuring components that would be very difficult to analyse. One of the future steps will be the inspection and reverse engineering of gear teeth that we have only physical samples of, which our customers want to reproduce and possibly improve. We rely on our measuring machine to perform these tasks in a more efficient and accurate way than we’ve been able to do so far with traditional tools”.

The company, established in 1968, manufactures high-quality gears and gearboxes. Over time it has developed and consolidated an in-depth expertise in the manufacturing of gears based on a customer’s drawing or on a sample, often producing small lots rather than large batches.

This is the reason that BP Riduttori products are extremely diverse and cover a wide range of different gears, from the most common spur gears and helical gears to Gleason spiral bevel gears, differential reduction gears, bevel gears, worm screws, drive shafts, gearbox speed multipliers, angled gear units and worm screw jacks.

Federico Bortolami, second-generation owner and technical director of the company explains: “The applications of gears in the real world are extremely varied and although gears may meet specifically defined requirements, they are subject to a good deal of variation. When the kinematic system that the gear is a component of has relatively simple characteristics, you can use off-the-shelf gears. However, as the system gets more complex and accuracy requirements get higher, dedicated gear profiles and couplings become necessary. They allow the correct, efficient and effective transmission of motion and minimise the wear, noise and loss of precision. As a result, the mechanical designer will create the gear geometry as a function of the characteristics of the machine that is going to hold the gear, not vice-versa. From the most traditional but more and more demanding applications for powertrains through to high-accuracy machines for the pharmaceutical industry, to gyro control mechanisms, each of them has different characteristics and requirements. “Our company did not want to step on the throttle with mass production. On the contrary, we wanted to make our experience of over 40 years available to those who require specialised components and consultancy at the design and manufacturing stage. We often support the technical departments of our customers to assess the best solution as early as the design stage. Less frequent, but not uncommon, are cases in which we have to reproduce and possibly alter existing gears whose geometric characteristics or mathematical models are unknown, and real reverse engineering is therefore required.”

As a solution to their dimensional inspection challenge, BP Riduttori recently purchased a DEA Global Silver 9.12.8 coordinate measuring machine, equipped with a TesaStar-sm indexable probe head, a Leitz LSP-X1 continuous scanning sensor and QUINDOS 7 software. Bortolami said: “Before acquiring a measuring machine, we used traditional measuring tools and equipment. These were certainly very reliable, but less effective on the other hand, and sometimes they struggled to provide an overall evaluation of not only gears but also drive shafts, slots and bearing seats. Opting for a tool like a measuring machine has therefore been the obvious choice. Our DEA Global Silver has a comprehensive range of equipment as regards to both sensors and software. We have a continuous scanning sensor, which is essential for the accurate probing of profiles. It is attached on an indexable head, allowing repeatable orientation in hundreds of positions in space. This enables us to access and measure even the most complex gears. With the high degree of specialisation in the field, we’ve opted for the QUINDOS measurement software, complete with several application modules dedicated to the various types of gears. This gives us a full detailed analysis of every gear type and allows us to generate inspection reports that go with our products and certify their quality. We can also rely on Curve Analyzer, a very useful application package for the quick analysis of the 2D profiles that are typical of our daily work”

The measuring system supplied by Hexagon Metrology supports various stages of the manufacturing process for the BP Riduttori gears. Some measurements are performed on drive shafts and bearing seats after the turning operations that are carried out before the gear teeth are cut. After machining and final processing of the gear teeth there is the metrological sampling of the lots, and in case of very particular gears or limited quantity runs, the certification of every individual part. The QUINDOS software and its application modules have been created with attention to the specific requirements of gear manufacturers, and this is apparent,” Bortolami continues, “It is unlike other more general packages, which require more processing and are not always capable of providing all the results we need. Moreover, a measuring machine is a general purpose tool that allows you to inspect not only the gear tooth characteristics, but also the geometry of drive shafts and wheels – all with a single system.”

The staff have gradually learnt how to operate the measurement system with one-on-one training from skilled Hexagon Metrology engineers. Bortolami goes on: “The measuring machine and the control and inspection software are very easy to use, but our applications are often rather complex and above all very varied. The advice provided by the Hexagon Metrology application engineers has been essential for us. They’ve helped us to better define methods and strategies for measuring components that would be very difficult to analyse. One of the future steps will be the inspection and reverse engineering of gear teeth that we have only physical samples of, which our customers want to reproduce and possibly improve. We rely on our measuring machine to perform these tasks in a more efficient and accurate way than we’ve been able to do so far with traditional tools”.

So, what does Federico Bortolami see in the future of his company? “We strive to be a supplier of highly specialised components, as we have been so far. Those who turn to us do not require just any gear. They have a problem to solve that requires expertise, analytical skills and flexibility, both in terms of quantities and quality. This is the added value we offer our customers and that we want to continue to offer”.