Aero engine compressor and turbine blade inspection

Dimensional measurement solutions for the quality assurance of aero engine compressor and turbine blades

Contact us

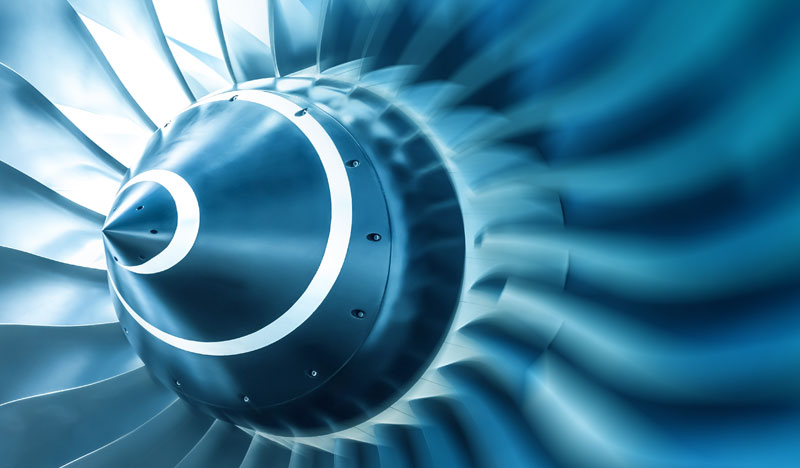

Compressor and turbine blades are essential components of the cold and hot sections in a turbofan, crucial to generating the power that propels the aircraft. Operating for long durations at high speeds and temperatures, the blades have to be produced and inspected to the highest quality.

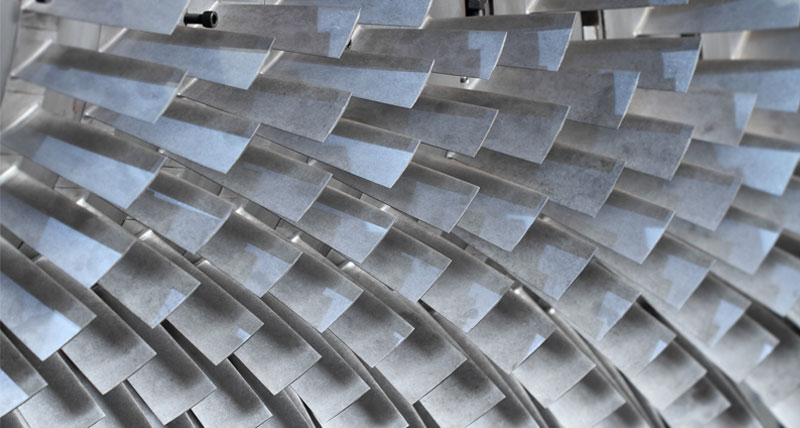

Blade profiles, thickness, and alignment have very tight tolerances to ensure aerodynamic efficiency and optimal energy conversion while avoiding blade failure. High-accuracy measurement is required for a complete check of the blade’s complex geometries, such as the curvature of the aerofoil’s leading and trailing edge, and intricate firtree blade roots. Alongside the challenge of measuring freeform surfaces, the requirement to inspect large volumes of aero engine blades can cause production bottlenecks.

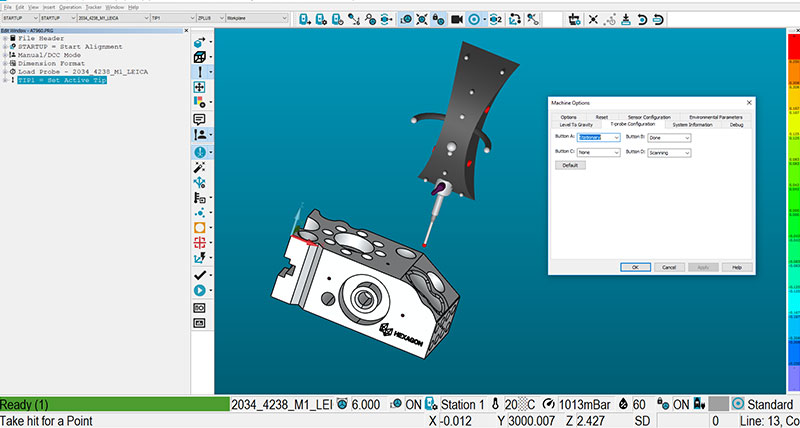

The ideal measurement solution combines high precision with increased throughput. Hexagon enables aero engine manufacturers to bring blade metrology closer to production, reducing inspection times with inline 3D coordinate measuring machines (CMMs) equipped with an automated part loading system. An additional rotary table increases access to blade features to reduce the need for reclamping.

Combining high-accuracy scanning probes with optical measurement helps manufactures achieve the minimised uncertainty and shorter cycle time required for increased blade manufacturing productivity. Hexagon’s blade-specialised CMM accommodates for surface types ranging from rough forged to micro-finish, while blade software enables user-friendly programming and automated measurement of crucial blade characteristics, including twist angle, chord length, and leading radius.

.jpg?h=428&iar=0&w=800&hash=DEECDDA621D750FFA8581DEE4E3C6E22)