QUINDOS 2019.2

Second release of QUINDOS’ two main versions per year adds the new VCMM II option to verify feature-specific measurement uncertainty.

Contact us

QUINDOS 2020.1 is the latest release of Hexagon’s world leading analysis tool which combines the metrological core competencies of the aerospace, energy, automotive, and engineering industries.

QUINDOS is a trusted partner due to its backward compatibility and provides a range of options developed in projects in an industrial setting. The core offers a comprehensive range of functions to realise metrological solutions for standard geometries and complex tasks.

QUINDOS 2019.2 launches the new option QUINDOS Virtual CMM – VCMM II for determining the specific measurement uncertainty of test features. The Physikalisch-Technische Bundesanstalt (PTB) verified model is based on the latest mathematical models and technological standards using the computer-based simulation according to VDI/VDE 2617 Sheet 7.

Click on ‘Features & Benefits’ below to learn more about the new option.

The QUINDOS version 2019 extends the functionality of the gearing modules:

- Determination of the grinding/cutting tool offset.

- Evaluation of the lead of the gradually narrowing tooth form in the direction of the face for the inspection of the grinding strategy for Broaches with ring grooves.

- Optimised and updated Hirth option serration.

- QUINDOS Gears offers a new all-in-one plot graphically which visualises the evaluations of helix and profile for a gear in a condensed format and the special measurement dimension over 3 balls has also been added.

-

Features & benefits

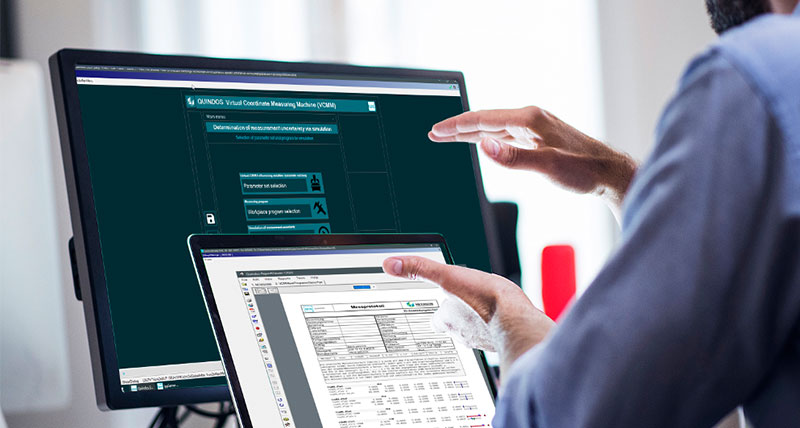

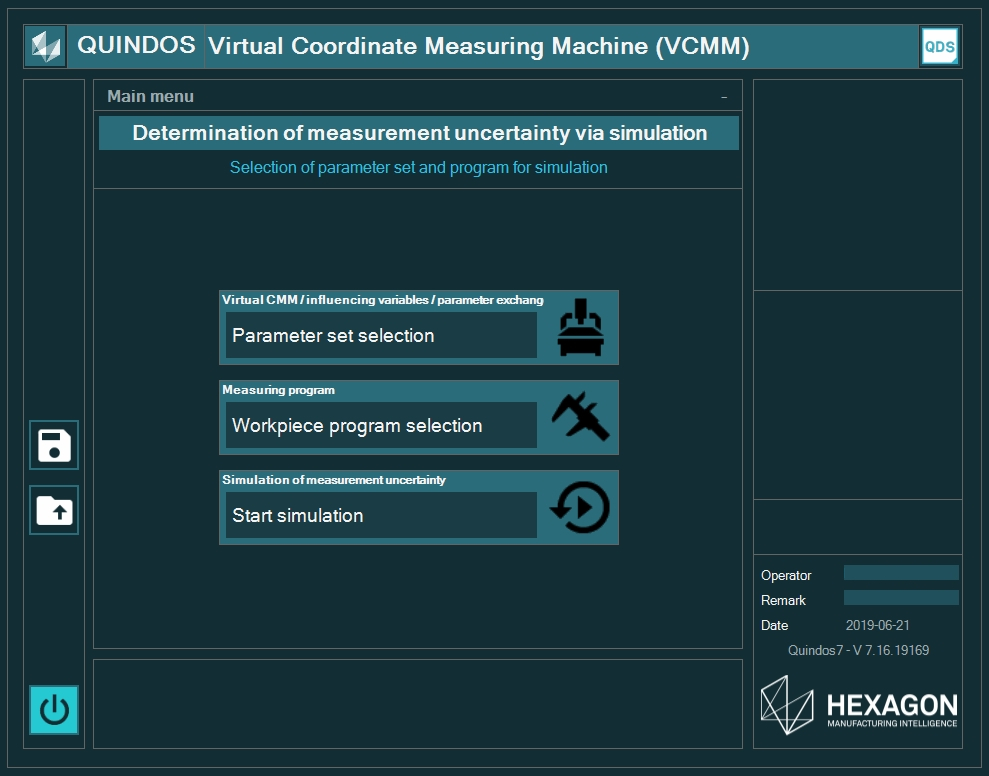

NEW: QUINDOS Virtual CMM – VCMM II option available

PTB verified Virtual CMM to simulate the feature-specific measurement uncertainty

The VCMM II option is used to determine and document the task-specific measuring uncertainty of tactile measurements on CMMs without rotary tables. The individual measuring uncertainty of the test features is determined according to the latest mathematical models from the PTB. The PTB’s numerical simulation is the current standard. It takes new influences and their correlations into consideration to reflect the demands of complex measurement tasks using the technological standards of today’s measuring devices. The influence of scanning, tools, tool changes, ambient conditions, and the workpiece itself are all part of this determined measuring uncertainty. The VCMM II option offers an efficient, reliable methodology to monitor and verify conformity of the measurements with current standards.

Simulation of feature-specific measuring uncertainty is carried out for each individual test feature after measurement. The simulation is based on the factors influencing measuring uncertainty determined on a real CMM. These are stored in a parameter set as a digital twin of the CMM.

The service team provides assistance during initial determination of the parameter set and carries out the residual error determination at the machine. The ambient conditions (temperature) and influencing factors are determined and documented. The residual error determination requires a valid acceptance test according to EN ISO 10360-2:2002-05. The measuring machine must be verified to be in specification.

Application-relevant influencing factors can be regularly recorded independently by the operator. Our personnel can provide the necessary training. You will receive information on best practices when creating the part programs and instructions on how to use the individual commands in the option. The duration (number of simulation runs) and timing of the simulation depend on the type of application.

They can be adjusted according to the individual measuring tasks in order to react flexibly to accuracy and efficiency demands. This QUINDOS solution provides a structured user interface to guide the user through the relevant steps from task definition to the final report. The measuring uncertainty can be output as a value individually for each feature on the report and also graphically. The graphical output can be differentiated for incoming and outgoing inspection, or according to the conventional QUINDOS graphic without separate illustration of the uncertainty. -

Technical data

Recommended System Requirements

Operating System

QUINDOS 2019.2 operates under 64-bit Windows 10. The minimum requirement is Windows® 10 Version 1607 and the recommended version is Windows® 10 Version 1803. This QUINDOS version can be used also on Windows 7® 64-bit, but the support and fixes for operating system related bugs will be limited.

Microsoft .NET Framework

If you do not have Microsoft .NET Framework 4.7.1 for Windows, the QUINDOS installer will install it for you.

Hardware

We recommend the following hardware configuration when using the QUINDOS software package including CAD options and when using QUINDOS in connection with the QUINDOS Reshaper option or the I++Simulator software package.- Processor:2GHz;4C and 8,25MB Cache

- RAM:32 GB, 2.666 MHz

- Graphic card:NVIDIA® Quadro® P4000, 8 GB, 4 DP (5820T)

- Hard drive:1 x 256 GB SSD HD, 1 x 1 TB SATA HD

- TFT-Monitor:24-inch (monitor resolution 1920 x 1200)

We recommend a second TFT-Monitor.

A second network interface card (required for machine communication)

Please check whether or not a serial interface is required for connecting to an older machine.

Please also note the information in the Release Notes.Release Notes