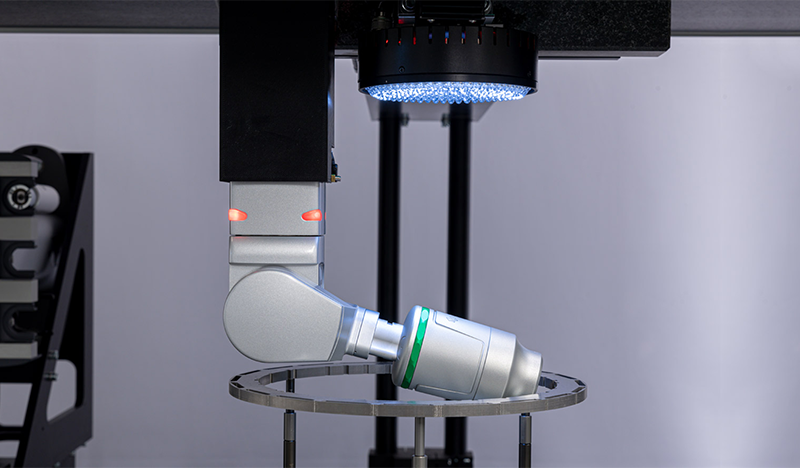

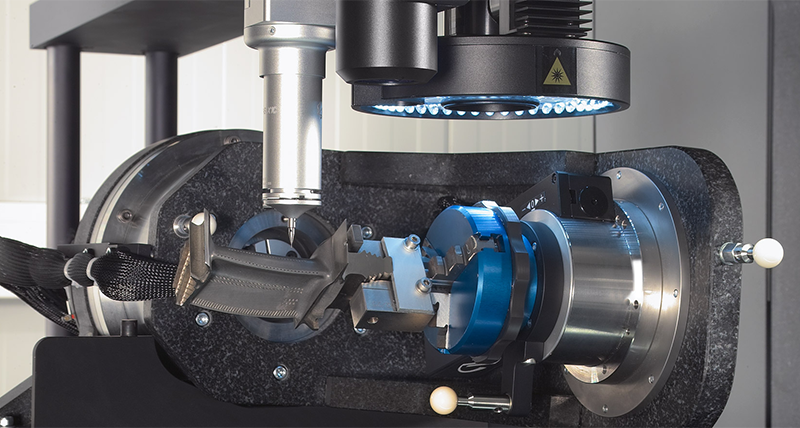

OPTIV Dual Rotary

Optimised part positioning offering single-setup-measurement.

Product enquiry

OPTIV Dual Rotary quickens inspection times by reducing the need for probe changes and the number of required translational axis (bypass) movements. During measurement, the part is rotated by defined angles; features that have already been measured are rotated automatically, maintaining original alignment of the workpiece.

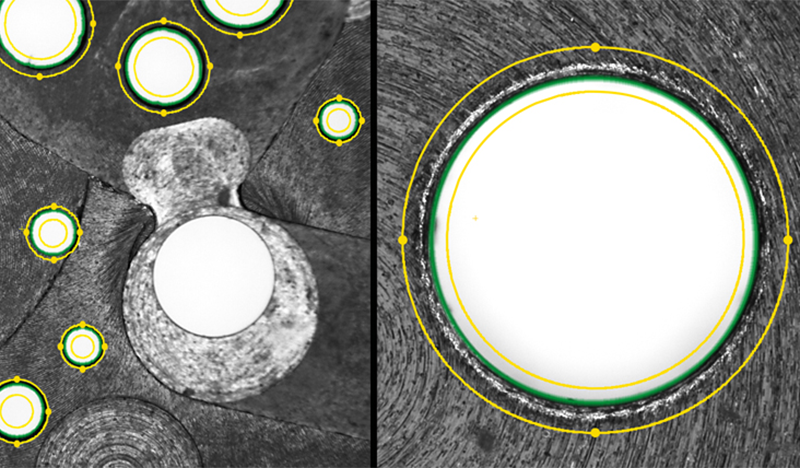

OPTIV Dual Rotary reduces measurement uncertainty by referencing measurements between features from different rotational positions. The tool also simplifies routine creation in PC-DMIS.

OPTIV Dual Rotary tables are built of stainless steel, offering high stiffness without compromising dynamic performance. It is perfect for inspecting drilling tools, injection nozzles, sleeves, gearwheels and other parts with features distributed around their circumference.

-

Features & benefits

Faster cycle times

Reduced reclampings, part repositioning, and probe changes.

Reduced measurement uncertainty

References measurements between features from different rotational positions. -

Downloads

-

Buy CMM accessories online

Buy CMM accessories online

Identify your spare parts with confidence and benefit from fast UPS delivery.