OPTIV multisensor technology

Enhance efficiency and flexibility in multisensor inspection.

Contact us

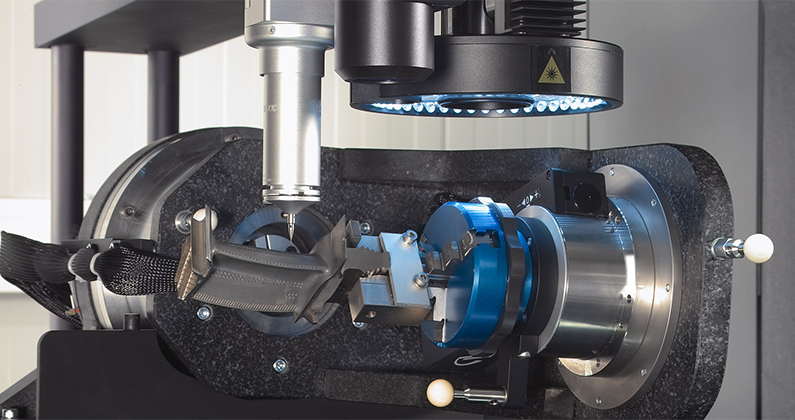

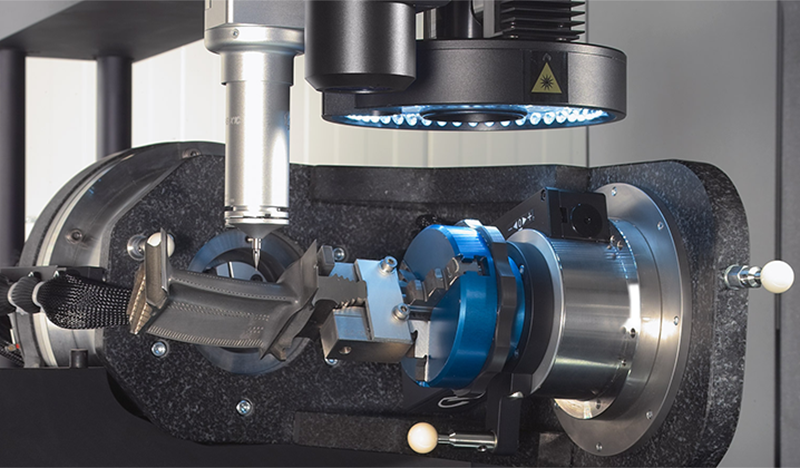

OPTIV Dual consists of three technologies purpose-built for multisensor operations, enabling users to drive productivity by enhancing application flexibility, reducing cycle times, and increasing accuracy.

Each tool has its own particular strengths and focus in terms of productivity enhancement, but all three are united by the fact that they make multisensor measurement simpler, more streamlined, and less time-consuming.

The OPTIV Dual technologies are:

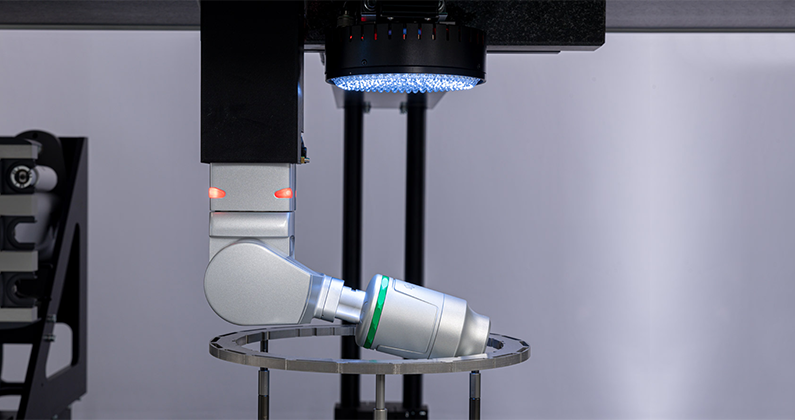

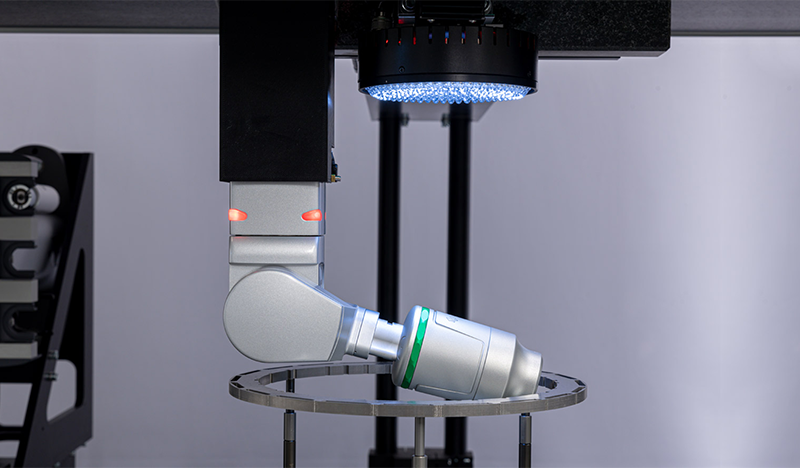

OPTIV Dual Z – offering collision-free accessibility to more measuring positions with two independent vertical axes, reducing the need for re-clamping.

OPTIV Dual Rotary – enabling accessibility to more measuring positions with automatic part rotation.

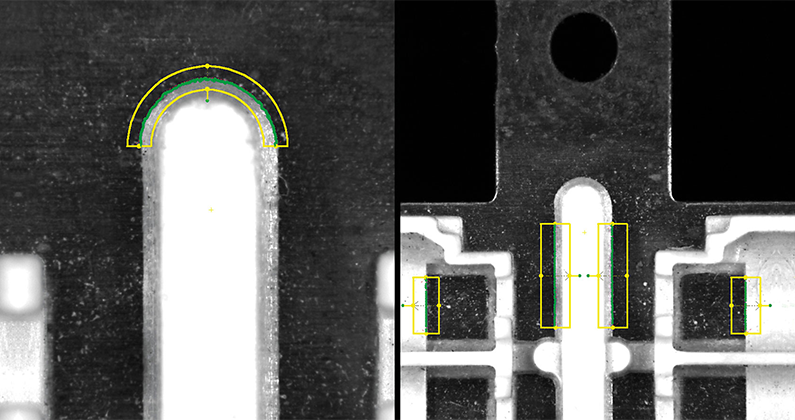

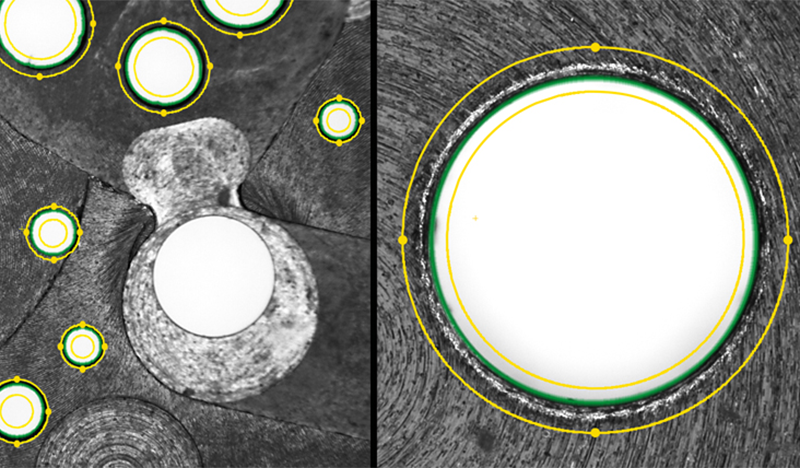

OPTIV Dual Camera – increasing application flexibility with automatic switching between high precision and high throughput zoom modes.

These tools can be installed as options on a range of Hexagon’s multisensor and optical coordinate measuring machines (CMMs).

Click on each of the OPTIV Dual technologies to learn more about how each tool can enhance inspection and increase productivity.