MSC CoSim

Where multiphysics gets real

MSC CoSim

Overview

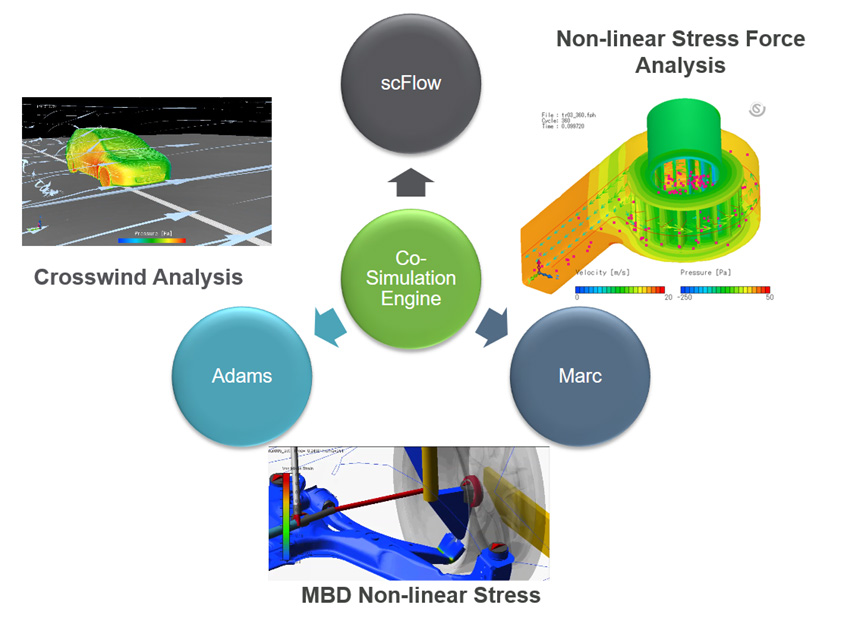

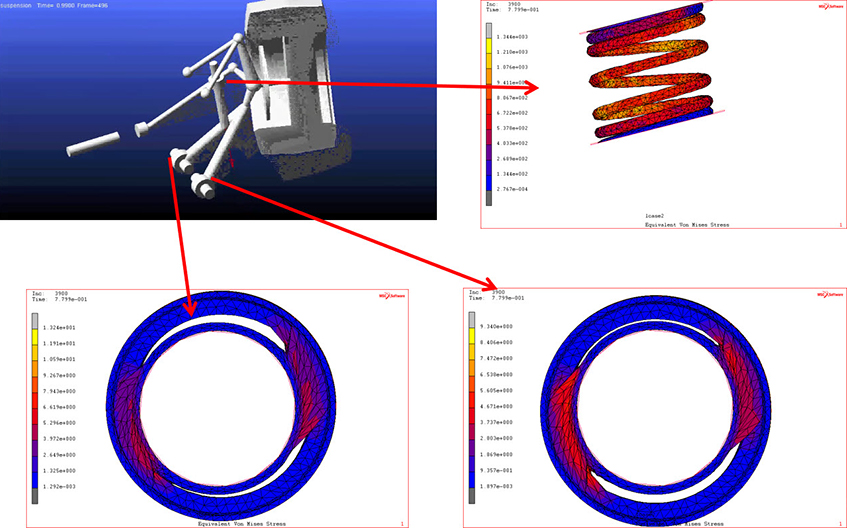

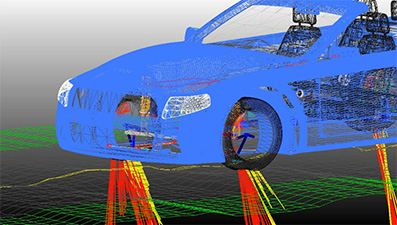

Co-simulation provides engineers with a unique, more complete & holistic performance insight by coupling together multiple simulation disciplines. Multibody dynamics (MBD), Computational Fluid Dynamics (CFD), and structural analysis (FEA) can be connected thanks to MSC CoSim. Depending on the type of analysis, engineers can use Hexagon’s solutions in two ways – Co-Simulation (applying multiple physics to the model simultaneously) or Chained Simulation (passing load case results from one analysis to the next).

Increased accuracy and precision

"The ability to quickly and easily look at alternatives with co-simulation at a time when we are not locked into any particular approach should make it possible to meet performance requirements with a lighter suspension that can improve the fuel economy of the vehicle." - Technical Expert at Endurance Attribute and Chassis CAE Department, Volvo

Faster analysis performance

"The Adams-Marc co-simulation capability more than satisfies our guideline of 'reasonable results in a reasonable time.' With up to a 90% reduction in computation time, optimization using advanced nonlinear FEA becomes practical. Such development provides a great benefit and is crucial for our product development and we are proud to work together with MSC in advancing the technology." - Chief Engineer, Litens Automotive Group

MSC Co-Simulation techniques

Depending on the type of analysis, engineers can use MSC solutions in two ways – Co-Simulation (applying multiple physics to the model simultaneously) or Chained Simulation (passing load case results from one analysis to the next).

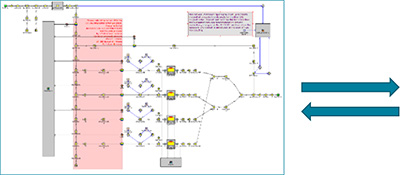

1. MSC CoSim engine

The MSC CoSim engine has been developed to provide a co-simulation interface for the direct coupling of different solvers/disciplines with a multiphysics framework. MSC CoSim enables engineers to set up co-simulation models between Adams, Marc, MSC Nastran, scFLOW and scSTREAM.

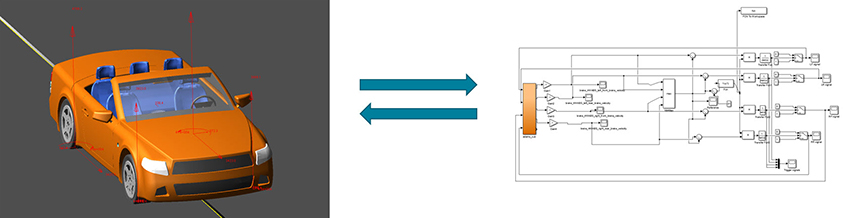

2. Other open co-simulation solutions

Besides the CoSim engine, Hexagon also supports a list of other co-simulation methodologies, including the Functional Mock-up Interface (FMI), Adams Marc Co-Simulation Interface (ACSI) and so on.

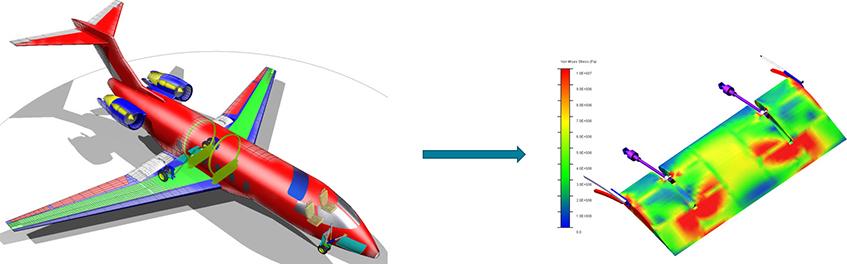

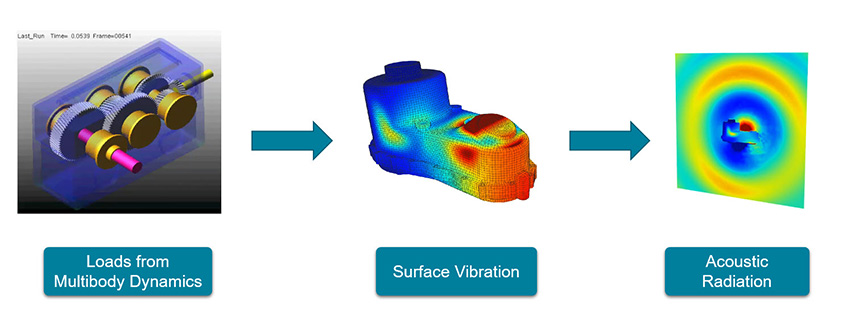

3. Chained simulation

Chained simulation allows CAE engineers from different departments to integrate multiple disciplines sequentially and improve the overall simulation accuracy. For example, passing the road loads data from an Adams Full Vehicle model to the downstream MSC Nastran model for the stress and durability analyses.

MSC Co-Simulation applications:

-

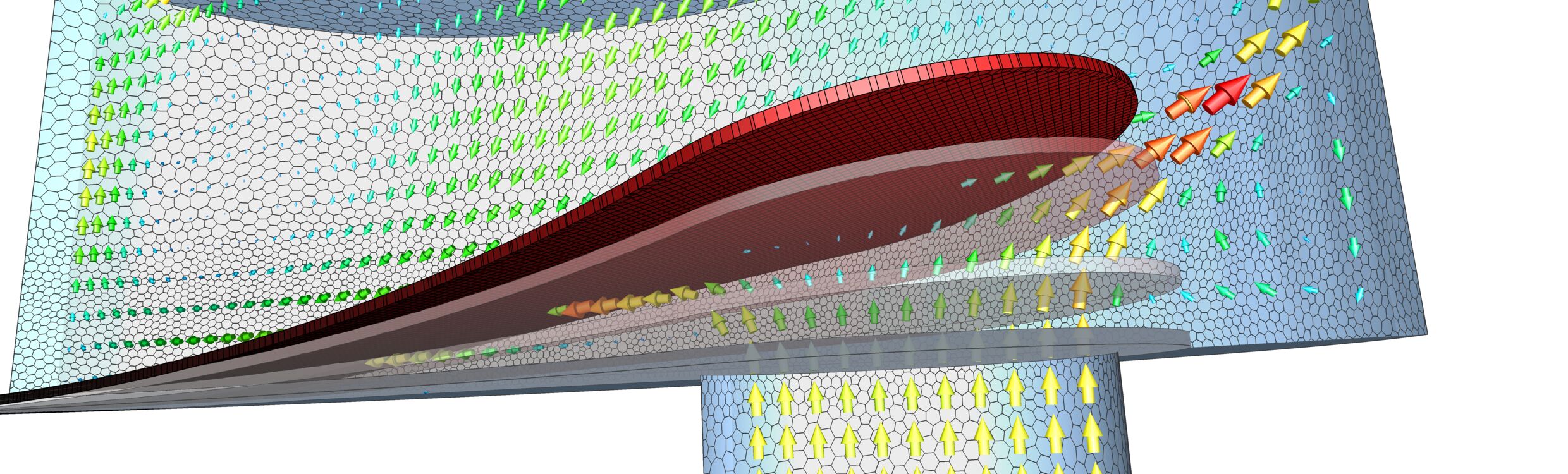

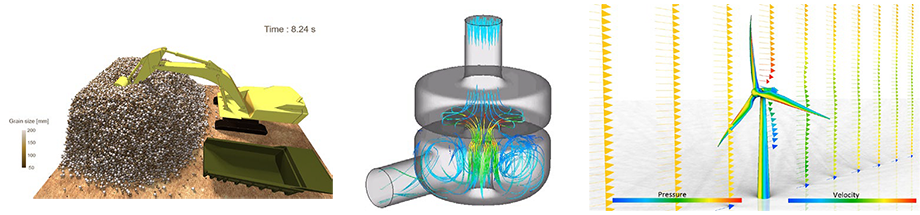

Fluids + Multibody Dynamics

Deployment of flaps on an aircraft wing

Crosswind Impact on Vehicle Dynamics

Vehicle driving through water puddle

Fuel tank sloshing

Buoyant logs floating under a bridge

-

Fluids + Structures

Flexible plate in a crossflow

Flag on a flag pole fluttering in a wind

Valve in a tank opening

Diaphragm valve distorting due to fluid force

Ship propeller simulation with fluid-structure interaction

Water jet hitting a pivoting flat plate

-

Multibody Dynamics + Structures

Vehicle battery scratched by obstacle

Wiper blade mechanism simulation

ATV hitting a curb

Forming process simulation

Suspension system simulation with nonlinear bushing

-

Multibody Dynamics + Controls

Validating control algorithms for industrial robots

-

Multibody Dynamics + 3D Environment

ADAS and Autonomous Driving Simulation

-

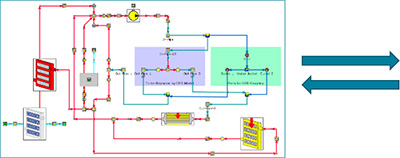

Fluids + 1D Simulation

Detailed combustion gasses simulation integrated with 1D system modeling

Detailed cooling water 3D analysis incorporated in the 1D system model

-

Multibody Dynamics + Structures + Acoustics

Noise prediction for gearbox/transmission systems

-

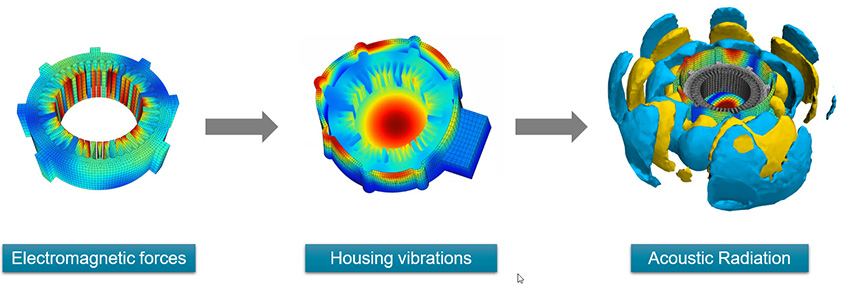

Electromagnetics + Structures + Acoustics

Acoustic analysis for electric motors

-

Fluids + Acoustics (Aero-acoustics)

Noise study for exhaust system