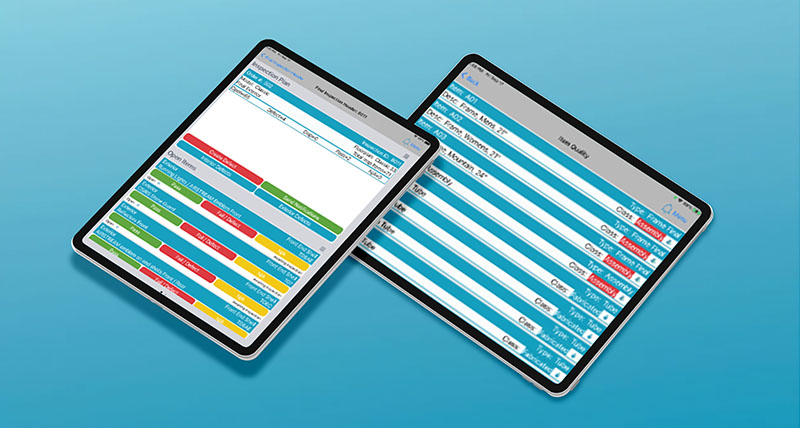

Digital Quality Inspection

A dynamic, adaptable inspection suite for high-complexity manufacturing products which standardise a quality team's means and methods for quality inspections for receiving, mid-stream and final/pre-delivery inspections. These items are reported in real-time to provide insights to management team to properly adjust manufacturing processes.

Standardise inspection methods

We're excited to announce that Hexagon Xalt Solutions is now Nexus Connected Worker!

Nexus Connected Worker solutions are designed to break down information silos and transform manual processes into efficient digital workflows, ensuring manufacturing excellence and efficiency.

Digital Quality Inspection

Digital Quality Inspection digitises your workflow by integrating withy our existing systems of record, promoting collaboration and improving communication throughout your company.

- Eliminate paper, scanning and duplicate data entry

- Derive actions from inspection results automatically

- Immediately notify relevant personnel of defects

- Analyse root cause trends and key issues in real-time

- Access granular data to minimize the cost of poor quality

- Standardise inspection methods across the quality team

- Generate instant internal and external feedback loops

- Automatically generate and assign punch-list items

- Collect objective evidence (photos) of compliance

- Increase speed and accuracy if quality technicians

- Reduce risk and exposure from warrant claims