How Hexagon creates value for the automotive industry

Harnessing data for a smarter and more sustainable automotive future

From electric and hydrogen powertrains to fully autonomous vehicles, the automotive industry is developing new generations of smarter, more sustainable vehicles.

Hexagon accelerates innovation with a digital-first, data-driven approach in design, manufacturing and operations.

The new mobility paradigm

The automotive industry is facing a digital revolution. Digital transformation of consumer technologies is driving demand for smarter, more connected and increasingly autonomous transportation, transforming the way vehicles are designed, developed and manufactured.

Future vehicles present new challenges. Where electric vehicles have fewer parts than combustion engine equivalents, complexity is added in systems such as power electronics and onboard computers. The supply chain needs to evolve and adapt to these changing requirements amid uncertainty about which innovations consumers will be willing to adopt.

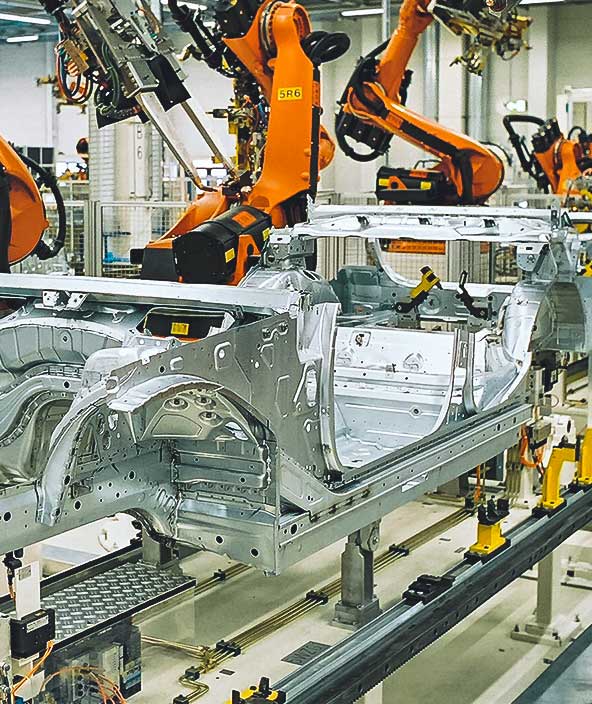

Automotive manufacturers are responding to this unpredictability by turning to increasingly digitalised business models. By digitally connecting every stage of the product lifecycle using advanced manufacturing solutions, automakers gain the agility and resilience they need to compete in the new mobility paradigm.

Driving future mobility forward

- Empowering automotive to address the challenges of human transportation with data-driven solutions is Hexagon’s commitment to the industry. Our smart manufacturing solutions are helping automotive industry players— including OEMs, suppliers, start-ups and big tech — to navigate the shift to electric and imagine new business models that deliver success for the industry and create value for the consumer.

- CAE simulation tools create digital twins that enable new vehicle design concepts to be tested faster, reducing development costs. Virtual design validation and optimisation help reduce physical prototyping, which lowers costs and reduces waste.

- Manufacturing process simulation ensures manufacturability and predicts issues prior to production.

- New designs are informed by measured quality data from previous iterations for shorter design cycles and faster issue resolution.

- Connected data-sharing throughout the vehicle lifecycle provides insights to inform future development.